The Emergence of Pipe Polishing Machines A Key Player in Manufacturing

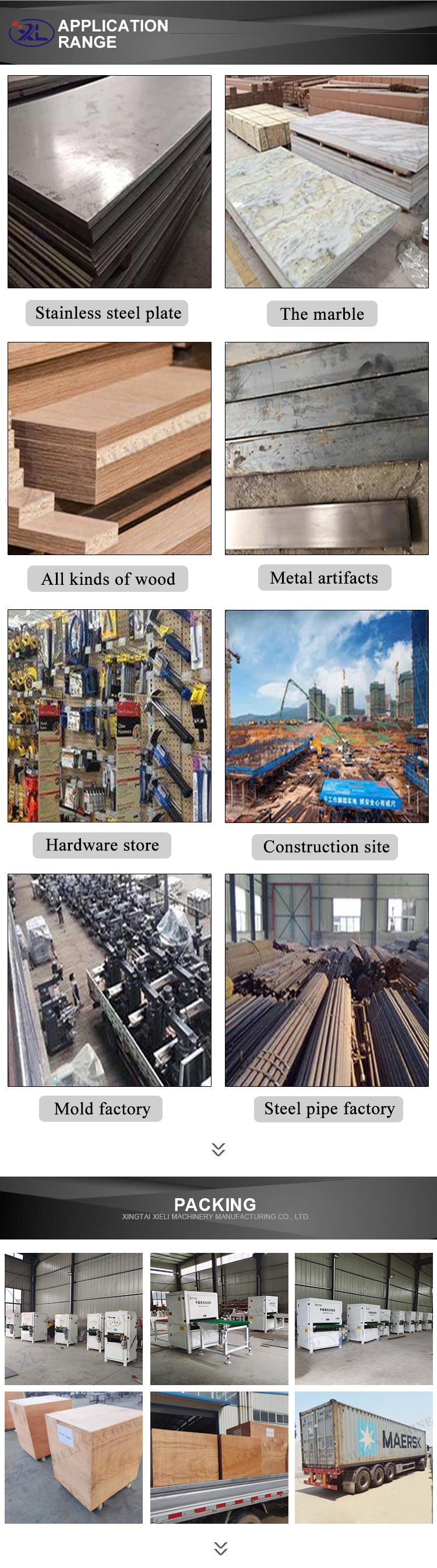

In the modern manufacturing landscape, precision and efficiency are paramount. Among the vital equipment that facilitates these requirements are pipe polishing machines. These machines have gained significant prominence in various industries, including automotive, aerospace, and construction, for their essential role in enhancing the quality of metal pipes. The demand for high-quality pipe polishing machines has spurred numerous manufacturers to cater to this evolving market, offering sophisticated solutions tailored to specific needs.

Understanding Pipe Polishing Machines

Pipe polishing machines are specialized tools designed to polish and finish the surfaces of metal pipes. They are essential for removing rough edges, burrs, and oxidation, which can negatively impact both the appearance and performance of the pipes. These machines employ various techniques, including mechanical polishing, grinding, and buffing, ensuring that the final product meets industry standards for smoothness and aesthetics.

There are several types of pipe polishing machines available, such as automatic and semi-automatic models, each suited for different production scales and requirements. Automatic machines offer higher efficiency and consistency, making them ideal for large-scale manufacturing operations. In contrast, semi-automatic machines provide more flexibility for smaller batches, allowing manufacturers to customize their processes according to specific customer demands.

The Advantages of Using Pipe Polishing Machines

Investing in a high-quality pipe polishing machine carries numerous advantages. Firstly, it significantly enhances the surface finish of the pipes, making them more appealing for consumers. A well-finished pipe can make a product stand out in the market, particularly in industries where aesthetics are also important.

pipe polishing machine for sale manufacturer

Secondly, proper polishing can improve the pipe's resistance to corrosion and wear. By eliminating imperfections and creating a smoother surface, manufacturers can extend the lifespan of the pipes. This attribute is particularly crucial in industries like construction and automotive, where durability and reliability are paramount.

Additionally, these machines can boost productivity by streamlining the polishing process. Instead of relying on manual labor, which can be time-consuming and prone to errors, pipe polishing machines can operate at high speeds with consistent results. This leads to lower operational costs and faster turnaround times, allowing manufacturers to meet the increasing demands of their customers.

Selecting the Right Manufacturer

With a multitude of manufacturers available, choosing the right pipe polishing machine supplier is critical. Key factors to consider include the manufacturer’s experience in the industry, the technology used in their machines, and the level of customer support they provide. Reputable manufacturers often offer warranties, service packages, and training for their machines, ensuring that clients can operate them effectively.

Moreover, it is essential to assess the customization options available. A variety of industries may require specific polishing techniques or machine configurations, and a good manufacturer should be able to cater to those unique needs.

Conclusion

The rise of pipe polishing machines has transformed manufacturing processes across various sectors. Their ability to deliver high-quality finishes while enhancing productivity makes them invaluable assets for any business involved in pipe production. As the demand for advanced manufacturing solutions continues to grow, the role of specialized equipment, particularly pipe polishing machines, will only become more critical. Investing in a reliable pipe polishing solution from a reputable manufacturer can provide manufacturers with a significant competitive edge, ensuring they can meet market demands with efficiency and excellence.