Understanding Pipe End Grinding Machines Importance and Applications

In the world of pipe fabrication, precision and quality are paramount. Among the various processes involved in pipe manufacturing and preparation, end grinding is a critical operation aimed at achieving the desired finish and specifications for pipes. This article explores the significance of pipe end grinding machines, their applications, benefits, and key features that make them indispensable in the fabrication industry.

What is a Pipe End Grinding Machine?

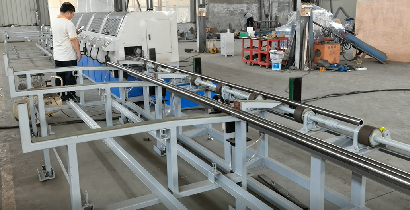

A pipe end grinding machine is a specialized piece of equipment designed to grind and finish the ends of pipes. This process is essential for ensuring that the pipe ends are uniformly smooth, properly aligned, and meet the required mechanical and aesthetic specifications. The machines utilize various grinding techniques and tools to remove imperfections, burrs, and other irregularities from the pipe ends, rendering them ready for further processing or installation.

Importance of Pipe End Grinding

1. Quality Assurance One of the primary reasons for employing pipe end grinding machines is to ensure the quality of the final product. Smooth and correctly aligned pipe ends facilitate better fittings, which are crucial for preventing leaks and ensuring the structural integrity of piping systems.

2. Increased Safety Properly ground pipe ends are less likely to cause accidents during handling and installation. Rough or jagged edges can pose significant safety risks for workers, especially in environments where pipes are frequently moved and connected.

3. Enhanced Performance The performance of piping systems can be negatively affected by poorly finished pipe ends. By ensuring that the ends are ground to precise specifications, the overall efficiency of fluid transport can be improved. This is particularly vital in industries such as oil and gas, chemical processing, and water treatment.

Applications of Pipe End Grinding Machines

Pipe end grinding machines find applications across a variety of industries

- Construction In construction, these machines help finish pipes used in structural frameworks, plumbing, and HVAC systems. Properly prepared pipe ends ensure easier installation and reduce the risk of failures in joint connections.

pipe end grinding machine quotes

- Manufacturing In manufacturing facilities, pipe end grinding machines are utilized to process raw pipes before they are integrated into larger machines or systems. This aids in maintaining quality control and adherence to industry standards.

- Shipbuilding The shipbuilding industry employs pipe end grinding to ensure that all piping systems aboard vessels are safe, efficient, and reliable. Given the harsh environments marine vessels operate in, properly finished pipe ends are crucial for longevity and performance.

- Oil and Gas In the oil and gas sector, where pipes transport fluids under high pressure, the necessity for smooth and uniformly ground pipe ends cannot be overstated. These operations are subject to stringent industry regulations regarding safety and integrity.

Key Features of Pipe End Grinding Machines

Modern pipe end grinding machines come equipped with several advanced features that enhance their functionality and efficiency

- Automated Operation Many machines are designed with automation capabilities, allowing for consistent and efficient grinding without the need for constant manual intervention. This not only saves time but also reduces human error.

- Versatility Some machines are capable of handling various pipe sizes and materials, making them suitable for diverse industrial applications. This adaptability is essential for manufacturers dealing with different types of piping.

- Precision Engineering High-quality grinding machines utilize precision engineering techniques to ensure that each pipe end is ground to exact specifications. This level of accuracy is crucial for industries where tolerances are tight and standards are strict.

- Safety Features Modern machines often incorporate safety features such as automatic shut-off functions and protective guards to ensure operator safety during the grinding process.

Conclusion

Pipe end grinding machines represent an essential component of the pipe fabrication process, promoting quality, safety, and performance across various industries. As technological advancements continue to evolve in this field, the capabilities and applications of these machines will expand, further emphasizing their importance in modern manufacturing and construction practices. Investing in a reliable and efficient pipe end grinding machine is not just a choice for manufacturers; it is a necessity for those committed to delivering quality products to their clients.