The Significance of Pipe Buffing Machines in Manufacturing A Focus on Exporters

In the world of manufacturing, maintaining quality and finishing is integral to ensure the longevity and aesthetic appeal of products. One particular machine playing a crucial role in this domain is the pipe buffing machine. As industries worldwide increasingly emphasize quality, the demand for pipe buffing machines has surged, particularly among exporters who are tapping into international markets.

Understanding Pipe Buffing Machines

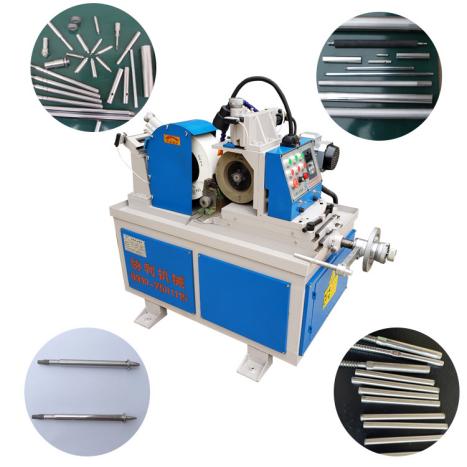

A pipe buffing machine is specifically designed to polish and buff pipes made from various materials, including metal, plastic, and composites. This machine enhances the surface finish, removing imperfections such as scratches, oxidation, and other blemishes that can occur during production or handling. The use of buffing machines leads to a brighter, smoother surface, improving not only the visual appeal of the pipes but also their resistance to corrosion and wear.

The Role of Exporters

Exporters of pipe buffing machines play a vital role in meeting the global demand for high-quality manufacturing equipment. They bridge the gap between manufacturers in different countries and the advanced technology needed for effective production. By ensuring the availability of these machines, they contribute significantly to enhancing the overall manufacturing processes in various sectors, including automotive, construction, and even decorative works.

Market Trends

The market for pipe buffing machines has been influenced by several trends. One notable shift is the increased use of automation in manufacturing processes. Many exporters are focusing on providing automated buffing machines that require minimal human intervention, thereby increasing production efficiency and reducing labor costs. This trend aligns with the overarching move towards Industry 4.0, where smart machines and automated processes dominate the manufacturing landscape.

Another trend is the growing environmental consciousness among manufacturers. Exporters are responding by offering eco-friendly buffing solutions, which not only reduce energy consumption but also incorporate sustainable materials in their manufacturing processes. This alignment with environmental regulations is particularly relevant as companies worldwide strive to meet stricter environmental standards.

pipe buffing machine exporter

Technological Advancements

Technological advancements have significantly impacted the performance and capabilities of pipe buffing machines. Modern models are equipped with features like variable speed motors, which allow manufacturers to adjust the buffing process according to the specific material and desired finish. This versatility is a significant selling point for exporters, as it caters to a diverse clientele with varying needs.

Moreover, enhanced safety features are now standard in many pipe buffing machines, addressing industry concerns about worker safety. Exporters that provide machines with built-in safety protocols not only demonstrate their commitment to employee well-being but also enhance their marketability.

Challenges Faced by Exporters

Despite the growing demand, exporters of pipe buffing machines face several challenges. Fluctuating global economic conditions can impact sales, and trade regulations differ significantly across countries, complicating the logistics of exporting machinery. Additionally, maintaining quality standards is crucial; any defects can lead to costly returns or damage to a brand’s reputation.

Exporters must also be attuned to the changing needs of the market. As manufacturers increasingly seek customized solutions, being able to offer tailored machines that meet specific requirements can significantly influence an exporter's success.

Conclusion

The importance of pipe buffing machines in the manufacturing sector cannot be understated. They serve as essential tools that enhance quality and durability, ultimately leading to better products. As a direct link to the global manufacturing community, exporters play an indispensable role in facilitating access to these machines, keeping pace with technological advancements, and responding to evolving industry trends. By addressing current challenges and leveraging opportunities in the market, exporters of pipe buffing machines are paving the way for a brighter future in international manufacturing.