The Role of Pipe Buffing Machine Companies in Manufacturing

In the intricate world of manufacturing, precision and finishing are paramount. Among the various tools and equipment that contribute to achieving a polished and refined product, pipe buffing machines hold a significant position. These machines are designed to smooth and polish the surface of pipes of varying materials, ensuring they not only meet aesthetic standards but are also free from imperfections that might affect their performance. In this article, we explore the role of pipe buffing machine companies in the manufacturing sector, their offerings, and the impact of their technology on industry standards.

What Are Pipe Buffing Machines?

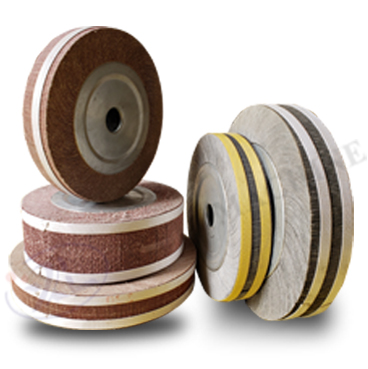

Pipe buffing machines are specialized equipment used to refine the surfaces of pipes, tubes, and other cylindrical objects. These machines utilize various abrasive materials, including buffing wheels, belts, and pads, to polish the surfaces to a high sheen. The primary objective is to eliminate any scratches, blemishes, or oxidation, thus enhancing not only the appearance of the products but also their durability and resistance to corrosion.

The Importance of Pipe Buffing Machine Companies

The significance of companies producing pipe buffing machines cannot be overstated. These enterprises invest in research and development to design machines that are both efficient and effective. They focus on creating machines that can cater to different materials, including stainless steel, aluminum, and copper, thus expanding their client base across diverse industries such as automotive, aerospace, and construction.

Furthermore, these companies often prioritize automation and user-friendliness in their designs. Modern pipe buffing machines are equipped with advanced technology that allows operators to execute polishing tasks with minimal manual intervention. This development is vital in today’s fast-paced manufacturing environment, where efficiency can significantly affect production timelines and overall costs.

Product Offerings

pipe buffing machine companies

Pipe buffing machine companies typically offer a range of products to address various polishing needs. Some machines are designed for heavy-duty industrial applications, capable of handling large volumes of pipes, while others cater to smaller-scale operations. Additional features may include adjustable speed settings, varying buffing attachments, and integration capabilities with existing production lines.

Besides standalone machines, many companies also provide comprehensive solutions, including buffing compounds and training resources for operators. This holistic approach ensures that clients not only acquire the right equipment but also the knowledge needed to operate these machines effectively and maintain them for longevity.

Innovation and Sustainability

As industries increasingly focus on sustainability, pipe buffing machine companies are also adapting to these changes. Many are developing environmentally-friendly polishing materials and methods that reduce waste and lower the carbon footprint associated with manufacturing processes. These innovations not only align with global sustainability goals but may also provide cost benefits to clients through reduced material usage and energy consumption.

Moreover, the integration of smart technology in manufacturing processes, including the use of IoT (Internet of Things) for monitoring and predictive maintenance, is becoming more prevalent. Pipe buffing machine companies are beginning to incorporate these technologies into their machines, allowing for real-time data collection and analysis. This capability enables businesses to optimize operations and reduce downtime, further enhancing efficiency.

Conclusion

In conclusion, pipe buffing machine companies play a crucial role in the manufacturing industry by providing the essential equipment needed for surface finishing. Their continuous innovation in design, automation, and sustainability is vital in advancing manufacturing processes and meeting modern industry demands. As manufacturing continues to evolve, the contributions of these companies will not only impact product quality but also drive efficiency and environmental responsibility in manufacturing practices. Whether in automotive production, aerospace components, or construction materials, the significance of pipe buffing machines cannot be overlooked.