The Importance of Pipe Belt Polishing Machines in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, achieving high-quality finishes on metal products is crucial. Among the various tools and machines used in this domain, pipe belt polishing machines have emerged as indispensable equipment for the fabrication and finishing of metal pipes and tubes. This article delves into the importance, functionality, and advantages of pipe belt polishing machines and why they are vital to modern manufacturing processes.

Understanding Pipe Belt Polishing Machines

A pipe belt polishing machine is specially designed to polish and finish metal pipes and tubes, ensuring a smooth, aesthetically pleasing surface that is free from imperfections and welding marks. These machines utilize an abrasive belt that moves swiftly around a roller, allowing for efficient material removal and polishing. The process not only enhances the visual appeal of pipes but also improves their resistance to corrosion and wear.

Applications in the Industry

Pipe belt polishing machines are widely used across various sectors, including

1. Construction In the construction industry, polished pipes are often used for railings, scaffolding, and structural supports. The smooth finish enhances safety by providing better grip and minimizing sharp edges.

2. Automotive The automotive sector utilizes polished pipes for exhaust systems and decorative trims. A refined surface improves both the aesthetic quality and performance of vehicles.

3. Food and Beverage In the food processing industry, cleanliness is paramount. Polished pipes are easier to clean and maintain, reducing the risk of contamination.

4. Furniture and Interior Design Polished metal tubes are increasingly popular in modern furniture design, offering sleek appearances and enhancing overall product value.

Functionality of Pipe Belt Polishing Machines

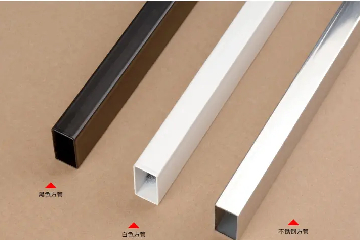

pipe belt polishing machine products

The operation of pipe belt polishing machines is fairly straightforward. The process begins with inserting the metal pipe into the machine. The operator selects an appropriate abrasive belt according to the desired finish – ranging from coarse to fine grits. Once set, the machine's motor drives the belt, which glides against the surface of the pipe. The movement can be adjusted to provide various angles and speeds, allowing for precision polishing tailored to specific requirements.

Most modern machines incorporate features such as adjustable speed controls, automatic belt tracking, and flexible polishing arms to accommodate various pipe diameters and lengths. This flexibility is essential, as it allows manufacturers to quickly switch between different products without significant downtime.

Advantages of Pipe Belt Polishing Machines

Employing pipe belt polishing machines comes with a host of benefits, making them a valuable investment for manufacturers

1. Efficiency These machines significantly reduce the time required for polishing compared to manual methods. High-speed operation enables manufacturers to maintain productivity levels while achieving superior surface finishes.

2. Consistency Automated polishing ensures uniform results across large batches of pipes. This consistency is critical for manufacturers that need to comply with specific industry standards.

3. Versatility Pipe belt polishing machines can be adjusted to polish various materials, including stainless steel, aluminum, and brass. This versatility makes them suitable for a wide range of applications and industries.

4. Cost-Effectiveness While the initial investment in pipe belt polishing machinery may be substantial, the long-term cost savings through increased efficiency and reduced labor requirements make them an economically viable option.

5. Improved Safety By automating the polishing process, these machines mitigate the risks associated with manual polishing, such as hand injuries or exposure to hazardous polishing compounds.

Conclusion

In conclusion, pipe belt polishing machines play a pivotal role in enhancing the quality and durability of metal pipes in various industries. Their efficiency, versatility, and ability to deliver consistent results make them a smart investment for manufacturers seeking to improve their production processes. As industries continue to prioritize quality and aesthetic appeal in their products, the demand for advanced polishing technologies like pipe belt polishing machines is anticipated to grow. Embracing this technological advancement not only supports higher production standards but also paves the way for innovation and progress in modern manufacturing.