Pipe Polishing Machines Enhancing Efficiency in Metal Fabrication

In the ever-evolving landscape of metal fabrication, pipe polishing machines have emerged as essential tools for manufacturers looking to enhance productivity and product quality. These machines are specifically designed to polish metal pipes, ensuring a smooth finish that not only meets aesthetic standards but also improves corrosion resistance. As the demand for polished pipes increases across various industries, from construction to automotive, the search for high-quality pipe polishing machines becomes crucial.

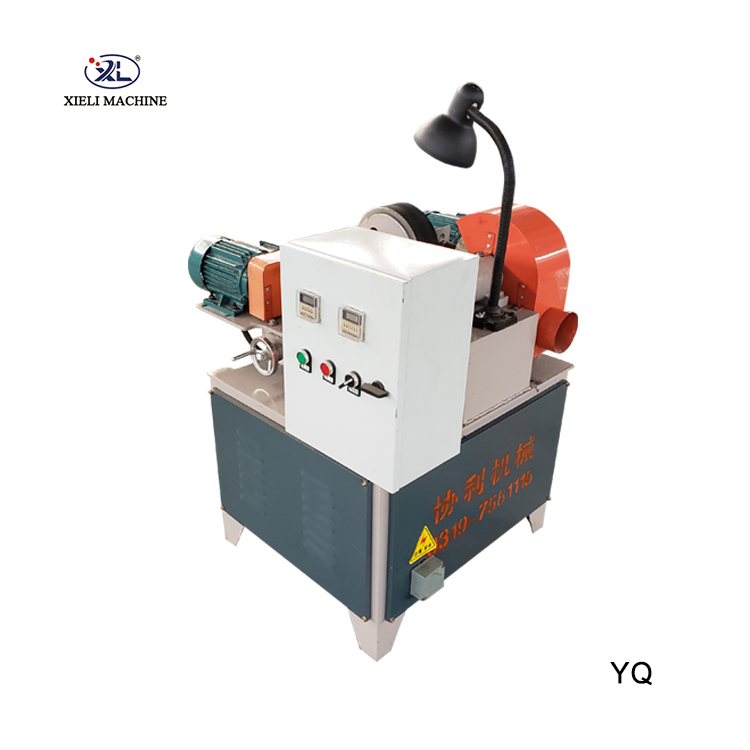

Factories focusing on pipe polishing have recognized the need for reliable and efficient machinery. The right machine can significantly reduce labor costs and time, leading to increased output. Many manufacturers now offer a range of pipe polishing machines equipped with advanced technology that allows for precision and control. Features such as adjustable speed settings, automatic feeding systems, and customizable polishing techniques make these machines versatile enough to handle different pipe sizes and materials.

Moreover, the growing emphasis on sustainability has driven factories to adopt more energy-efficient machines. Modern pipe polishing machines are designed to minimize energy consumption while maintaining high performance levels. This not only reduces operational costs but also aligns with environmental standards, making them an attractive option for manufacturers aiming to enhance their eco-friendly credentials.

pipe polishing machine for sale factories

In the quest for the best pipe polishing machines, many factories are turning to specialized suppliers who offer a variety of models tailored to specific needs. These suppliers often provide comprehensive service packages, including installation, training, and ongoing maintenance. Such support is invaluable, especially for factories that may be investing in these machines for the first time.

When considering a pipe polishing machine for sale, it is essential for factories to evaluate their specific requirements, including the volume of pipes to be polished, the desired finish quality, and the available budget. Investing in the right machine can lead to significant long-term savings through improved efficiency and reduced labor costs.

In conclusion, pipe polishing machines play a pivotal role in enhancing the efficiency of metal fabrication processes. With advancements in technology and a focus on sustainability, manufacturers are now better equipped to meet the high demands of the market. As factories continue to seek out reliable and efficient solutions, the role of specialized pipe polishing machines will undoubtedly grow, further shaping the future of the industry. Embracing these innovations will not only help manufacturers stay competitive but also ensure they deliver high-quality products to their customers.