Pipe End Grinding Machine Manufacturers Ensuring Precision and Efficiency in Metalworking

In the realm of metalworking and fabrication, the importance of precision cannot be overstated. One critical component of ensuring the integrity and functionality of pipes used in various industries is the process of end grinding. Pipe end grinding machines are specifically designed to provide clean, precise edges on pipe ends, making them essential for applications in plumbing, HVAC, automotive, and many other sectors. As industries continue to evolve, the demand for high-quality pipe end grinding machines has surged, leading to a competitive market for manufacturers.

Understanding Pipe End Grinding Machines

Pipe end grinding machines are specialized equipment that smoothens and shapes the ends of pipes before they are assembled or welded. These machines are crucial for removing burrs, preparing surfaces for welding, and ensuring a perfect fit in pipe joints. By providing a consistent finish, they not only enhance the appearance of the pipes but also contribute to the overall strength and reliability of the pipelines.

Manufacturers of pipe end grinding machines focus on advanced technology, ensuring their products are capable of handling various pipe materials, including stainless steel and carbon steel. Machines may vary in size and features, from simple manual grinders to fully automated CNC (Computer Numerical Control) machines that allow for high-volume production with minimal human intervention.

Key Features of Quality Pipe End Grinding Machines

When evaluating pipe end grinding machine manufacturers, several critical features should be considered

.1. Precision Engineering The accuracy of the grinding process is paramount. High-quality machines are designed to deliver precise tolerances, ensuring that the finished pipe ends meet required specifications.

2. Versatility Manufacturers that produce machines capable of handling a variety of pipe sizes and materials are advantageous for businesses that need flexibility in their operations.

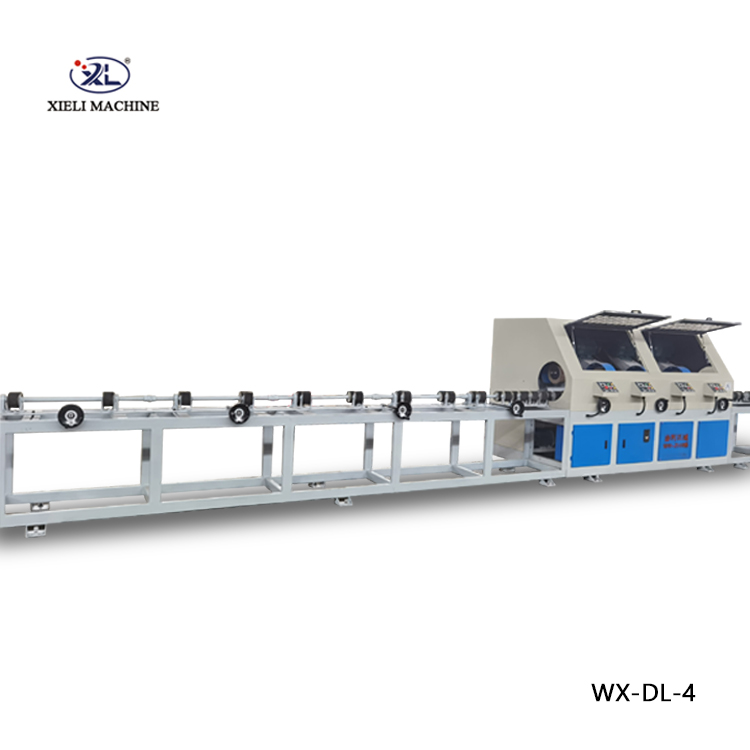

pipe end grinding machine manufacturers

3. Ease of Use Modern machines with user-friendly interfaces can significantly reduce training time and improve operational efficiency. This is essential in busy manufacturing environments where time is money.

4. Durability and Maintenance Investing in robust machines minimizes downtime due to repairs. Manufacturers that prioritize the use of high-quality materials in their construction offer longevity and lower total operating costs.

5. Technical Support and Service A reliable manufacturer should provide strong after-sales support, including maintenance services and spare parts availability, ensuring that machines remain operational over time.

The Market Landscape

The landscape of pipe end grinding machine manufacturers is broad, with established companies and emerging players alike. Leading manufacturers often invest significantly in research and development to innovate and enhance machine capabilities. They may also participate in global trade shows and exhibitions to showcase their latest models and technological advancements.

Emerging manufacturers are increasingly adopting smart technologies, such as IoT (Internet of Things) connectivity, allowing for real-time monitoring and data analysis. This not only enhances machine efficiency but also provides valuable insights into operational performance.

Conclusion

As industries continue to demand high precision and efficiency, the role of pipe end grinding machines becomes increasingly vital. Manufacturers who focus on quality, versatility, and technological advancement will undoubtedly thrive in this competitive market. For businesses looking to enhance their manufacturing processes, investing in top-notch pipe end grinding machines is a crucial step towards achieving operational excellence and ensuring the reliability of finished products.