Exploring the Role of Paragon RC-12 Centerless Grinders in Manufacturing

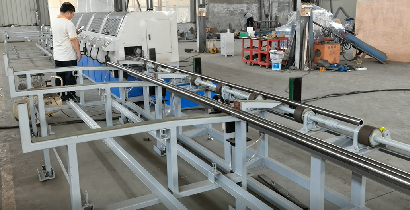

In the ever-evolving world of manufacturing, precision and efficiency are paramount. Among various machines that play a crucial role in ensuring these factors, the Paragon RC-12 centerless grinder stands out as a key tool in the industry. This remarkable machinery not only enhances productivity but also guarantees the high-level accuracy required for modern manufacturing processes.

The Paragon RC-12 centerless grinder is designed to handle a wide range of workpieces with varying lengths, diameters, and shapes, making it an essential asset for companies in different sectors. Whether it's automotive parts, aerospace components, or general machining tasks, the versatility of the RC-12 allows manufacturers to streamline their operations and minimize waste. The ability to process materials in a continuous manner, without the need for fixtures, significantly reduces setup times and operational costs, leading to improved overall efficiency.

One of the standout features of the Paragon RC-12 is its robust construction, which ensures durability and longevity. Manufactured using high-quality materials, this grinder is designed to withstand the rigors of heavy-duty use. The machine's precision-engineered components work in tandem to deliver superior grinding performance, resulting in smooth, consistent finishes that are essential for quality products. This precision is crucial, as it impacts not only the aesthetic appeal of the final product but also its functionality and compatibility with other components.

paragon rc-12 centerless grinder companies

Another significant advantage of the Paragon RC-12 centerless grinder is its user-friendly design. Equipped with intuitive controls and an ergonomic layout, operators can easily learn to operate the machine efficiently. This reduces the learning curve for new employees and minimizes the risk of errors during production. The grinder also features advanced automation capabilities, allowing manufacturers to integrate it into existing production lines seamlessly. With programmable settings, companies can optimize their grinding processes, adjusting parameters to meet specific production requirements without compromising quality.

Furthermore, the Paragon RC-12's adaptability extends to a variety of materials. Whether working with metals, plastics, or composite materials, this grinder can handle diverse applications, making it a versatile choice for manufacturing firms. Its capability to grind various types of workpieces with different hardness levels increases its appeal and relevance in a competitive market.

As companies strive to stay ahead of the curve in a fast-paced industry, investing in advanced machinery like the Paragon RC-12 centerless grinder becomes crucial. The combination of precision, efficiency, and adaptability provided by this machine can be a game-changer for many manufacturing enterprises. By incorporating the RC-12 into their operations, companies can enhance their production capabilities, improve product quality, and ultimately achieve greater customer satisfaction.

In conclusion, the Paragon RC-12 centerless grinder represents a significant advancement in manufacturing technology. Its capabilities not only meet the demands of modern production but also set new standards for efficiency and precision. As companies continue to look for ways to innovate and optimize their processes, the RC-12 stands out as a reliable choice that meets the diverse needs of the industry. Investing in such machinery is not just about meeting current demands; it is also about preparing for future challenges and opportunities in the ever-changing landscape of manufacturing.