The Role of Paragon Centerless Grinding Machines in Modern Manufacturing

In the realm of precision machining, centerless grinding has established itself as a critical process, particularly in industries that demand high efficiency and precision. Among the leading manufacturers of centerless grinding machines, Paragon stands out as a noteworthy player. Renowned for their innovation and quality, Paragon centerless grinding machines are sought after by various sectors worldwide. This article delves into the significance of Paragon centerless grinding machines and their impact on the export market.

Understanding Centerless Grinding

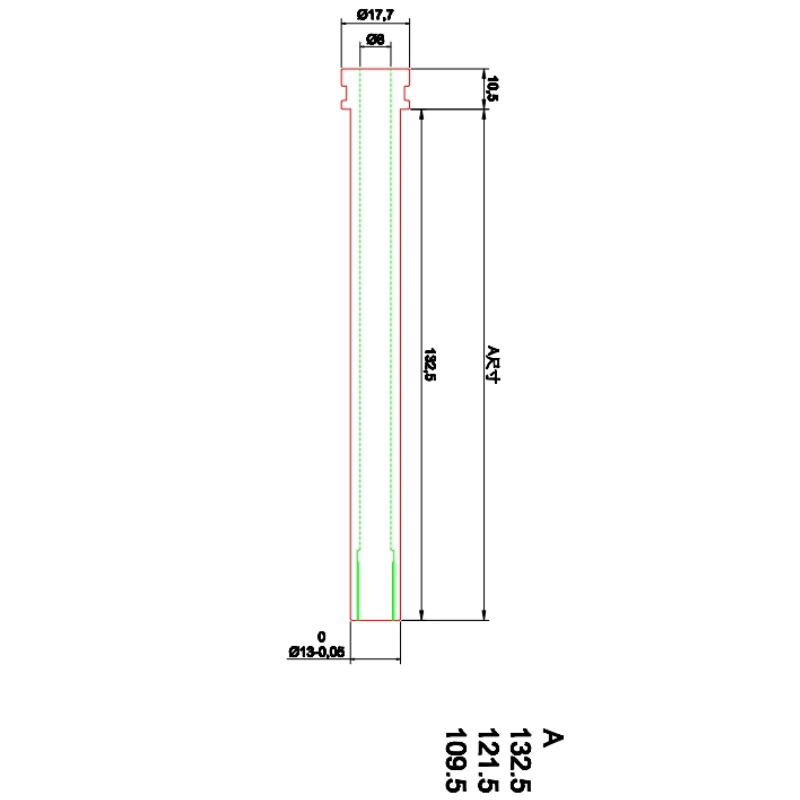

Centerless grinding is a unique process that allows for the efficient grinding of cylindrical workpieces without the need for a central axis. This method involves placing the workpiece between two grinding wheels a stationary wheel and a regulating wheel that controls the speed and position of the workpiece. This design enables continuous grinding, leading to higher throughput and productivity compared to traditional grinding methods.

Centerless grinding is typically used for producing shafts, pins, and other cylindrical parts that require exceptional dimensional accuracy and surface finish. The process can handle a wide range of materials, making it versatile in various manufacturing settings.

Why Paragon Centerless Grinding Machines?

Paragon Engineering Corporation, with decades of experience in manufacturing high-precision machinery, has positioned itself as a leader in the field of grinding technology. Their centerless grinding machines are favored for several reasons

1. Precision and Accuracy Paragon machines are engineered with advanced technology to ensure tight tolerances and superior surface finishes. This precision is crucial in industries such as automotive, aerospace, and medical, where even minor deviations can lead to significant issues.

2. Durability and Reliability Built from high-quality materials, Paragon centerless grinders are designed to endure the rigors of continuous operation. Their robust construction minimizes downtime, contributing to lower operating costs for manufacturers.

3. User-Friendly Design Modern Paragon machines come equipped with intuitive controls and programming interfaces, making them easy to operate. This ease of use reduces the training time for new operators and enhances overall productivity.

paragon centerless grinding machine exporters

4. Versatility The adaptability of Paragon centerless grinding machines allows them to accommodate various part sizes and shapes. This flexibility makes them ideal for manufacturers looking to diversify their product lines.

5. Innovative Technology Paragon continuously invests in R&D to integrate the latest technological advancements into their machines. This commitment to innovation ensures that users benefit from the most effective grinding solutions available.

The Global Export Market

As manufacturers worldwide seek reliable machining solutions, the demand for high-quality centerless grinding machines has surged. Paragon has successfully tapped into this global market, exporting their machines to countries across North America, Europe, Asia, and beyond.

One of the factors contributing to the success of Paragon exports is their ability to comply with international standards, ensuring that their machines meet the regulatory requirements of different markets. This compliance not only builds trust with international customers but also enhances the competitive edge of Paragon's offerings.

Moreover, Paragon leverages strategic partnerships and a robust distribution network to expand their reach. By collaborating with local distributors and agents, they ensure that customers receive support and service tailored to their regional needs.

Conclusion

The significance of Paragon centerless grinding machines in the manufacturing sector cannot be overstated. With their commitment to quality, precision, and innovation, Paragon has positioned itself as a leader in both the domestic and international markets. As industries continue to evolve and demand higher efficiency and accuracy, the role of advanced machinery like Paragon’s centerless grinders will remain pivotal.

In a global economy where competition is fierce, the ability to produce high-quality components quickly and cost-effectively is crucial for manufacturers. Paragon’s centerless grinding machines offer the perfect solution, enabling businesses to meet market demands while maintaining exceptional standards. As the trend toward automation and precision machining grows, Paragon is well-equipped to lead the way in the ever-changing landscape of manufacturing technology.