Understanding Palmary Centerless Grinding Machines A Supplier's Perspective

In the realm of precision machining, centerless grinding plays a pivotal role, particularly in the manufacture of cylindrical parts that require tight tolerances and high surface finishes. Among the leading suppliers in this field, Palmary stands out with its advanced technology and a commitment to quality. This article delves into the features, benefits, and significance of Palmary centerless grinding machines, showcasing why they are essential tools in various industries.

What is Centerless Grinding?

Centerless grinding is a machining process that involves feeding a workpiece between two wheels the grinding wheel that removes material and the regulating wheel that controls the workpiece's rotation and feed rate. Unlike traditional cylindrical grinding, centerless grinding does not require the workpiece to be mounted on centers, which enhances productivity and allows for continuous operation. The process enables manufacturers to produce high-precision components with minimal setup time, making it an attractive option for a variety of applications.

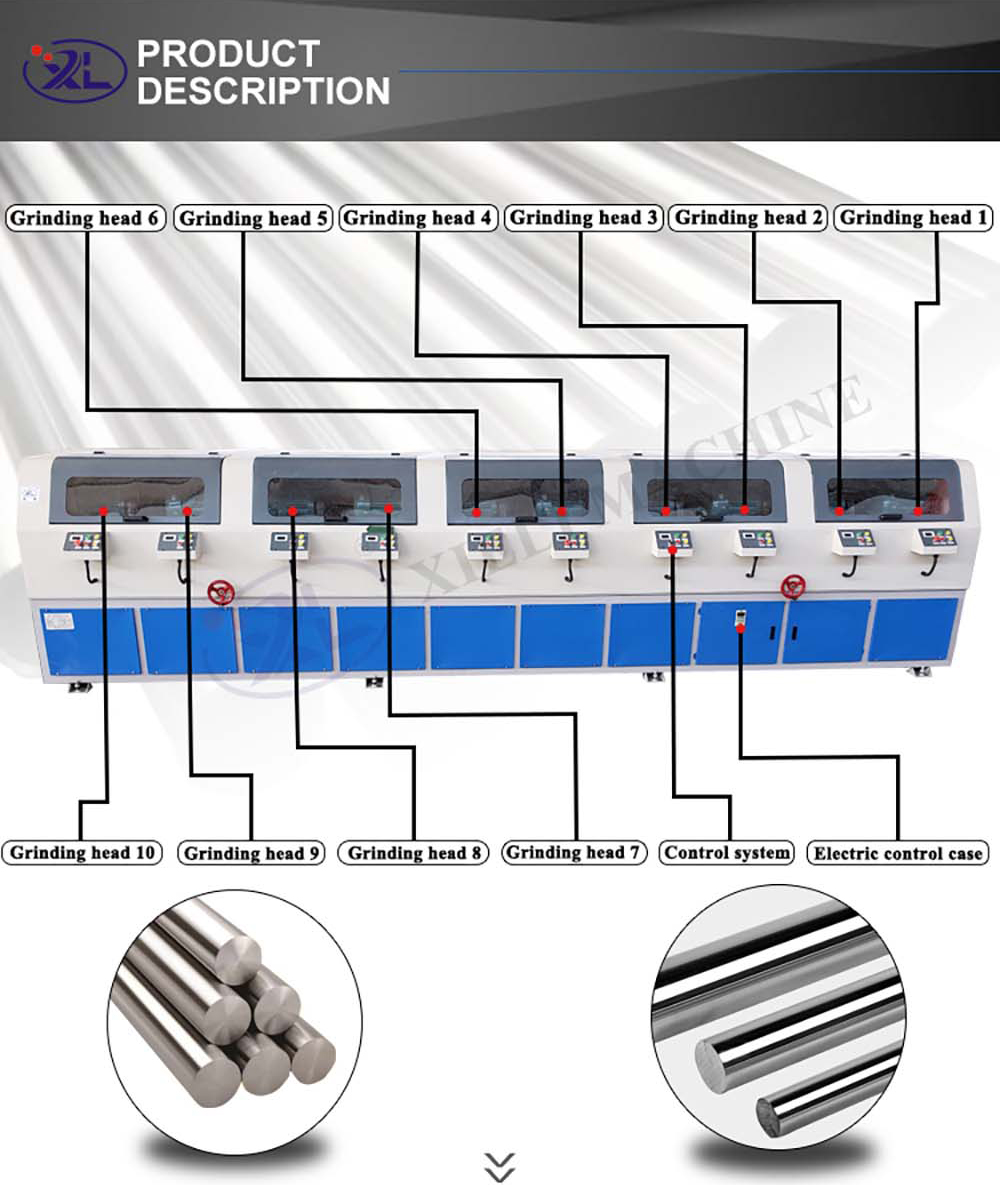

Key Features of Palmary Centerless Grinding Machines

Palmary’s centerless grinding machines are characterized by several key features that differentiate them from competitors

1. Precision Engineering Palmary machines are engineered to achieve exceptional accuracy and surface finish. They incorporate advanced grinding technologies that optimize performance and reduce wear, ensuring consistent quality in the final product.

2. Customization Options Understanding that different industries have unique requirements, Palmary offers customizable solutions. Clients can choose specific grinding wheels, workpiece sizes, and configurations to suit their operational needs.

3. Robust Build Quality Designed for durability, Palmary machines are built with high-quality materials that withstand the rigors of industrial use. This sturdy construction minimizes downtime due to maintenance and enhances the machine's overall lifespan.

4. User-Friendly Controls With a focus on operator comfort, Palmary machines feature intuitive control systems that simplify the grinding process. This user-friendly interface minimizes the learning curve for new operators, facilitating quicker integration into production lines.

palmary centerless grinding machine supplier

5. Automatic Loading and Unloading Many models come equipped with automatic loading and unloading mechanisms, which significantly improve efficiency by minimizing manual handling and reducing cycle times.

Advantages of Using Palmary Centerless Grinding Machines

1. Enhanced Productivity Due to their design and operation, centerless grinders from Palmary facilitate a high level of production efficiency. The continuous operation allows for the rapid processing of multiple workpieces, enhancing throughput.

2. Increased Precision The advanced grinding technology used in Palmary machines ensures that each workpiece is produced to exact specifications. This precision is crucial in industries such as aerospace, automotive, and manufacturing, where tolerances are stringent.

3. Cost-Effectiveness By reducing the need for extensive setups and manual work, Palmary centerless grinding machines help businesses lower their operational costs. The ability to produce high-quality components consistently also reduces waste and rework.

4. Versatility Palmary machines can handle a wide range of materials, from metals to plastics, making them suitable for numerous applications. This versatility allows manufacturers to diversify their offerings without investing in multiple types of machinery.

5. Excellent After-Sales Support As a reputable supplier, Palmary provides comprehensive after-sales service, including maintenance and support. This commitment ensures that clients can keep their machines in optimal condition, thereby maximizing their investment.

Conclusion

In conclusion, Palmary centerless grinding machines represent a significant advancement in precision machining technology. Their combination of precision engineering, user-friendly features, and customizable options make them a top choice for manufacturers looking to enhance productivity and quality. Whether in aerospace, automotive, or general manufacturing, the role of Palmary as a reliable supplier cannot be overstated. By investing in these innovative machines, businesses can not only streamline their processes but also ensure they meet the evolving demands of the market. For those seeking to elevate their manufacturing capabilities, Palmary’s centerless grinding machines are undoubtedly a worthy consideration.