Understanding Ovality in Centerless Grinding A Guide

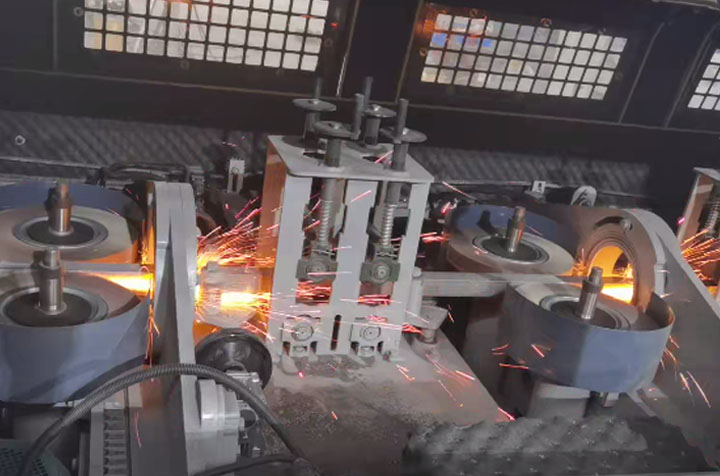

Centerless grinding is a critical process in the manufacturing sector, especially for producing precision machined components. However, one common challenge that manufacturers face is ovality, or the deviation from a perfect round shape, of the finished parts. This article aims to explore the concept of ovality in centerless grinding, its causes, and its implications for product quality.

Ovality arises when the workpiece does not maintain a cylindrical shape throughout the grinding process. Instead of a uniform diameter, the part exhibits variations that can affect its fit and function in assemblies. The key parameters that influence ovality include the machine setup, the type of grinding wheel used, and the material properties of the workpiece.

One significant factor in ovality issues is the alignment of the centerless grinder. If the machine is not properly set up, it can lead to uneven grinding pressure and inconsistent diameter. For instance, if the workpiece is not adequately supported or if the regulating wheel does not maintain uniform contact with the component, it may result in an oval shape instead of a cylindrical one. Additionally, the choice of grinding wheel, including its abrasive type and bonding, can impact the grinding efficiency and the surface finish. An improper wheel selection may introduce additional stresses that contribute to ovality.

ovality in centerless grinder quotes

Another aspect to consider is the machining environment. External factors such as temperature fluctuations and vibrations can adversely affect the grinding process. Maintaining a stable environment is essential for achieving the desired precision and consistency throughout production runs.

Understanding the implications of ovality is vital for manufacturers. Parts with significant ovality may not fit well in assemblies, leading to increased wear, reduced performance, and ultimately, potential failure in end-use applications. This can result in costly rework or scrap, impacting overall productivity and profitability.

To mitigate ovality issues, manufacturers can adopt various strategies. Regular maintenance of grinding machines, careful selection of grinding wheels, and thorough training for operators can significantly enhance the quality of the finished products. Furthermore, utilizing advanced measurement techniques to monitor roundness during the grinding process can help catch ovality early, allowing for timely adjustments.

In conclusion, addressing ovality in centerless grinding is essential for ensuring the production of high-quality components. By understanding its causes and implementing effective measures, manufacturers can improve precision, reduce waste, and enhance overall operational efficiency. As the competition in manufacturing intensifies, such quality control becomes increasingly critical to success.