Understanding OSHA Compliance for Centerless Grinder Suppliers

Centerless grinders play a pivotal role in manufacturing processes, providing precise grinding solutions for various components. However, along with their operational benefits comes the responsibility of ensuring compliance with the Occupational Safety and Health Administration (OSHA) standards. For suppliers of centerless grinders, it is crucial to understand these regulations to promote safety and efficiency in the workplace.

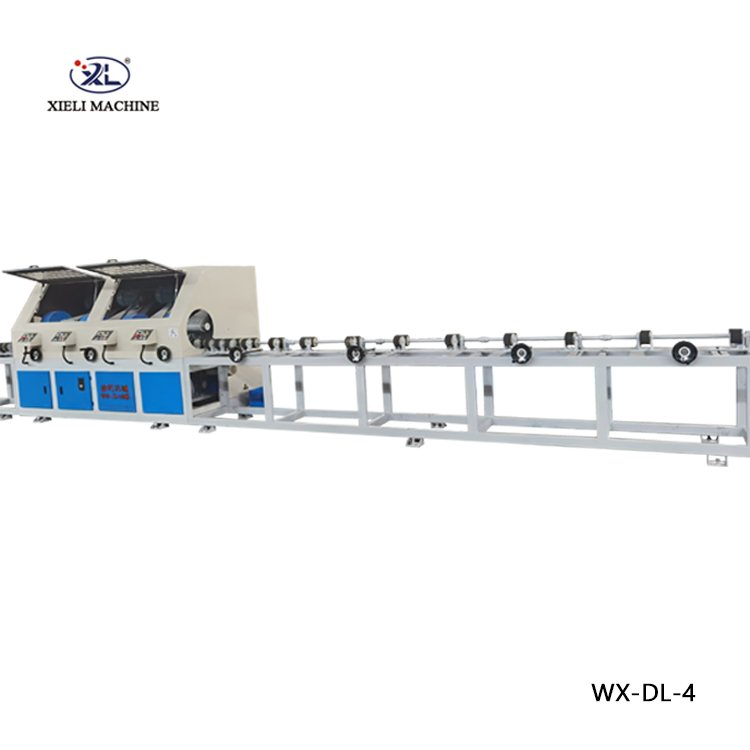

What is a Centerless Grinder?

A centerless grinder is a machine that allows workpieces to be ground without the need for clamping. The workpiece is held in place by a regulating wheel and an abrasive wheel, enabling precise shaping and finishing of cylindrical parts. This machine type is widely used in industries such as automotive, aerospace, and medical device manufacturing, where precision is paramount.

The Need for OSHA Compliance

Safety in the workplace is a top priority for manufacturers, and OSHA outlines stringent guidelines to ensure worker safety. Suppliers of centerless grinders must be cognizant of these regulations to not only protect their employees but also to avoid potential legal liabilities and financial penalties.

OSHA standards encompass various aspects of workplace safety, including equipment design, operational practices, and employee training. When supplying centerless grinders, it is essential that these machines adhere to OSHA regulations from the outset.

Key OSHA Regulations for Centerless Grinders

1. Machine Guarding One of the most critical aspects of OSHA regulations involves machine safeguarding. Centerless grinders must be equipped with appropriate guards to prevent workers’ hands and clothing from being caught in moving parts. Suppliers should ensure that their machines come with safety features that comply with OSHA standards.

osha centerless grinder supplier

2. Training Requirements OSHA emphasizes the importance of training for all employees who operate industrial machines. Suppliers must not only deliver the machines but also provide comprehensive training resources and manuals outlining safe operation practices. This training should cover machine functionality, the understanding of hazards, and emergency procedures.

3. Preventive Maintenance Regular maintenance of centerless grinders is vital to ensure their safe operation. OSHA recommends that suppliers offer guidelines for preventive maintenance schedules and practices to minimize the risk of accidents due to machine failure.

4. Hearing Conservation Centerless grinders can produce significant noise levels that may lead to hearing loss over time. OSHA's hearing conservation program should be integrated into the workplace safety plan, and suppliers should advise their clients on the selection of appropriate hearing protection measures.

5. Hazard Communication Suppliers are responsible for ensuring that all chemicals and materials used in conjunction with their machines are properly labeled and that safety data sheets (SDS) are provided. This ensures that workers are informed about potential hazards related to grinding operations.

The Role of Suppliers in Promoting Safety

As a key link in the manufacturing supply chain, centerless grinder suppliers have a significant responsibility to promote safety. By ensuring compliance with OSHA regulations, they can help their clients create a safer work environment. This, in turn, enhances productivity and reduces downtime caused by accidents.

Suppliers can also provide additional resources, such as safety audits and consultations, to help manufacturers better understand their compliance obligations and improve their safety protocols.

Conclusion

In summary, the supply of centerless grinders comes with not only technological innovation but also the critical responsibility of ensuring OSHA compliance. By understanding and adhering to OSHA regulations, suppliers can help their clients maintain a safe and efficient working environment. Ultimately, prioritizing safety not only protects workers but also strengthens the overall integrity and reputation of the manufacturing industry. By taking an active role in promoting safety standards, centerless grinder suppliers can contribute to a more sustainable future for manufacturing.