The Importance of Service for Old Centerless Grinding Machines

Centerless grinding machines are essential tools in the manufacturing industry, widely used for producing high-precision cylindrical components. Over time, many manufacturers rely on older models of these machines, which, while still functional, require more attention and care to ensure optimal performance. The service and maintenance of old centerless grinding machines play a critical role in enhancing efficiency, ensuring safety, and extending the lifespan of the equipment.

Understanding the Challenges

As with any machinery, older centerless grinding machines face specific challenges that can affect their functionality. Wear and tear from years of operation can lead to misalignment and degraded components, resulting in reduced accuracy and productivity. Moreover, technological advancements in grinding processes mean that older machines may not achieve the same efficiency and quality as contemporary models.

The average lifespan of a centerless grinding machine can exceed several decades if properly maintained. However, as components eventually wear out, operators must be vigilant about scheduling regular service and repairs. Ignoring these needs can lead to significant downtime and potentially costly repairs.

Regular Maintenance is Key

Regular service and maintenance are crucial for old centerless grinding machines. This involves a comprehensive examination of the machine's critical components, such as the grinding wheel and regulating wheel, as well as the hydraulic systems, bearings, and motors. Technicians should be trained to identify early signs of wear that could lead to more severe issues if left unaddressed.

Preventive maintenance should include routine cleaning, lubrication of moving parts, and the calibration of machine settings. Keeping the grinding wheels dressed and balanced also optimizes performance and tool life. Moreover, replacing worn belts, seals, and bearings can prevent further damage and ensure smooth operation.

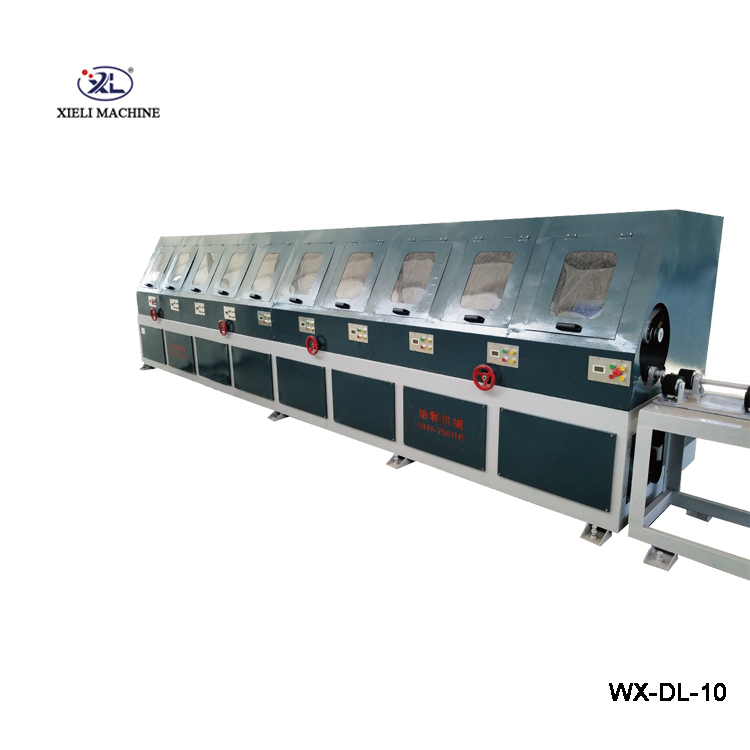

old centerless grinding machine service

Upgrades and Retrofitting

In addition to regular maintenance, many manufacturers are exploring upgrades and retrofitting options for their old centerless grinding machines. This can involve integrating modern technology such as CNC controls, automatic dressing systems, and advanced monitoring systems. These upgrades can dramatically improve productivity, precision, and functionality without the need to invest in entirely new equipment.

Retrofitting can provide manufacturers with a cost-effective solution to remain competitive in the market. It allows them to harness new technologies while retaining their existing machinery, making the most out of their investments. Furthermore, many service providers specialize in these upgrades and can guide businesses on the best approaches to realize their equipment's full potential.

The Role of Skilled Technicians

Having skilled technicians to perform the necessary service and maintenance on old centerless grinding machines is indispensable. These professionals not only understand the mechanical aspects of the machines but also possess the practical experience needed to troubleshoot issues effectively. They can advise on the best practices for maintaining equipment and provide training to machine operators on how to care for their machines properly.

Investing in training programs can ensure that operators are equipped with current knowledge about machining operations, which can further minimize wear and extend the lifespan of older machines.

Conclusion

In summary, the proper service and maintenance of old centerless grinding machines are vital for maintaining efficiency and reliability in manufacturing processes. Regular maintenance, necessary upgrades, skilled technicians, and a proactive approach to machine care can significantly impact production quality and cost-effectiveness. Manufacturers should recognize the importance of these endeavors to ensure their machinery remains a valuable asset in their production lines for years to come.