Understanding OEM Tube Buffing Machines Key Features and Benefits

In today's fast-paced manufacturing environment, the demand for high-quality surface finishes in metal products is ever-increasing. Among various finishing methods, buffing is pivotal for delivering a mirror-like polish that is essential for both aesthetic appeal and functional performance. Original Equipment Manufacturer (OEM) tube buffing machines have emerged as a vital solution for industries requiring precision and efficiency in their buffing processes. This article delves into what OEM tube buffing machines are, their working principles, and the benefits they provide to manufacturers.

What is an OEM Tube Buffing Machine?

An OEM tube buffing machine is a specialized piece of equipment designed for polishing tubular components made from various metals, including stainless steel, aluminum, and brass. These machines are tailored by manufacturers to meet specific customer requirements, ensuring that they can efficiently process tubes of different sizes, shapes, and materials. The main function of these machines is to achieve a smooth, glossy finish on the surface of the tubes, which not only enhances their appearance but also improves resistance to corrosion and wear.

How Do OEM Tube Buffing Machines Work?

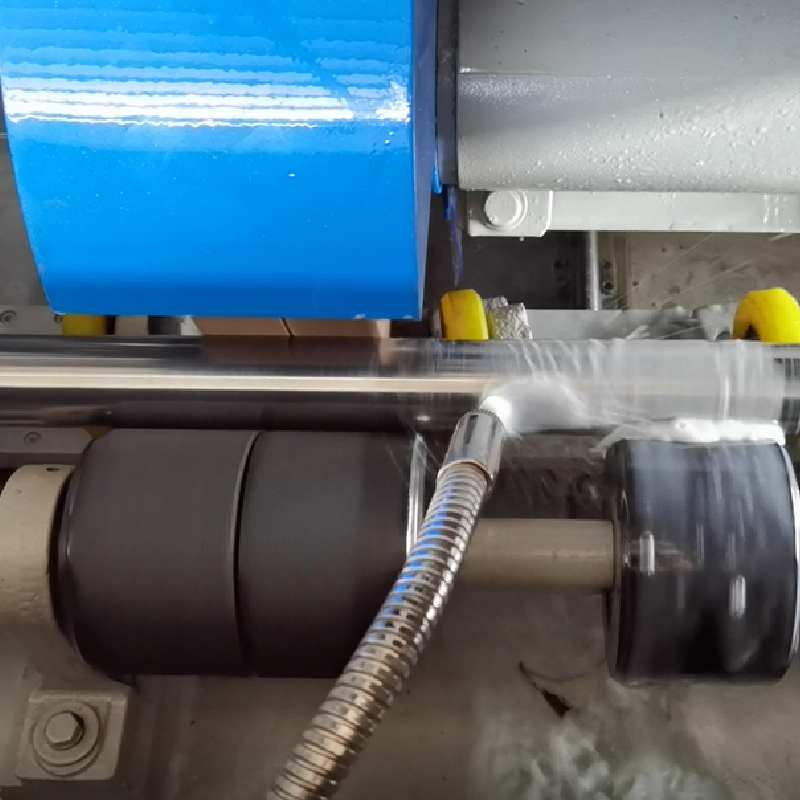

The operation of an OEM tube buffing machine is straightforward yet highly effective. The machine comprises several key components, including a buffing wheel, a motor, and a feeding mechanism. The process typically begins with the operator securing the tubular piece into the machine. Once in position, the buffing wheel, which is coated with abrasive compounds or polishes, rotates at high speeds, coming into contact with the tube as it is fed through the machine.

As the buffing wheel spins, it removes any imperfections, such as scratches or oxidation, on the surface of the tube. The use of different grades of abrasives allows for a graduated finish, starting from a coarser polish and moving to finer options to achieve the desired sheen. Some advanced models even incorporate automated features like adjustable speed settings and programmable cycles, ensuring consistent results and reducing labor costs.

The Benefits of OEM Tube Buffing Machines

Investing in an OEM tube buffing machine offers numerous advantages that significantly impact production capabilities

oem tube buffing machine

1. Enhanced Surface Finish OEM tube buffing machines can achieve exceptional surface finishes that are difficult to replicate by hand. This precision ensures that the final products meet industry standards and customer expectations.

2. Increased Productivity The automation and efficiency of these machines allow for higher throughput. Manufacturers can process larger batches of tubes in less time compared to manual buffing methods, ultimately increasing overall productivity.

3. Customization Options Since these machines are manufactured for specific needs, they can accommodate various specifications, including tube diameter, length, and material type. This flexibility is crucial for businesses that deal with diverse product ranges.

4. Cost-Effectiveness While the initial investment in an OEM tube buffing machine might seem significant, the long-term savings on labor costs, reduced material waste, and faster production times often justify the expense.

5. Consistency and Quality Control One of the major challenges in buffing processes is achieving uniformity. OEM machines ensure that each tube receives the same treatment, reducing variations in quality, which is essential for applications in industries like automotive, aerospace, and food processing.

6. Ease of Operation Most OEM tube buffing machines are designed with user-friendly interfaces and safety features, making them accessible to operators with varying levels of experience. This ease of use mitigates the risk of accidents and enhances overall workplace safety.

Conclusion

In conclusion, OEM tube buffing machines represent a critical investment for manufacturers aiming to improve their surface finishing processes. With their ability to deliver superior quality, increase efficiency, and provide customizable solutions, these machines have become indispensable in the metalworking industry. As businesses continue to strive for excellence in their products, the role of OEM tube buffing machines will undoubtedly grow, paving the way for better manufacturing practices and enhanced product offerings.