The Role of OEM in Feed Centerless Grinders

In the realm of precision grinding, feed centerless grinders have emerged as vital machines for various industrial applications. These grinders are particularly notable for their ability to process long, cylindrical workpieces with high efficiency and accuracy. Original Equipment Manufacturers (OEM) play a crucial role in the development, manufacturing, and supply of these grinders, ensuring that industries can meet their demanding production needs.

Understanding Centerless Grinding

Centerless grinding is a method that allows the grinding of workpieces without requiring them to be fixed on centers. The workpiece is held in place by a regulating wheel on one side and a grinding wheel on the other. This unique setup provides several advantages, including the ability to achieve high-precision finishes while maintaining excellent throughput rates. Typical applications range from producing shaft components to manufacturing automotive parts, medical instruments, and more.

The OEM Advantage

OEMs are instrumental in defining the standards and technologies associated with centerless grinders. They are responsible for designing machines that incorporate advanced engineering principles, ensuring that the grinders perform optimally in various operating conditions. In an ever-evolving market, OEMs are tasked with continually innovating their products to incorporate the latest technologies, such as automation and smart diagnostics, which enhance productivity and reduce downtime.

One of the main advantages of working with OEMs is their ability to supply customized solutions. Different industries have unique requirements regarding material types, dimensions, and tolerances. OEMs can offer tailored grinding solutions that meet specific customer needs, providing flexibility and precision that off-the-shelf solutions often lack.

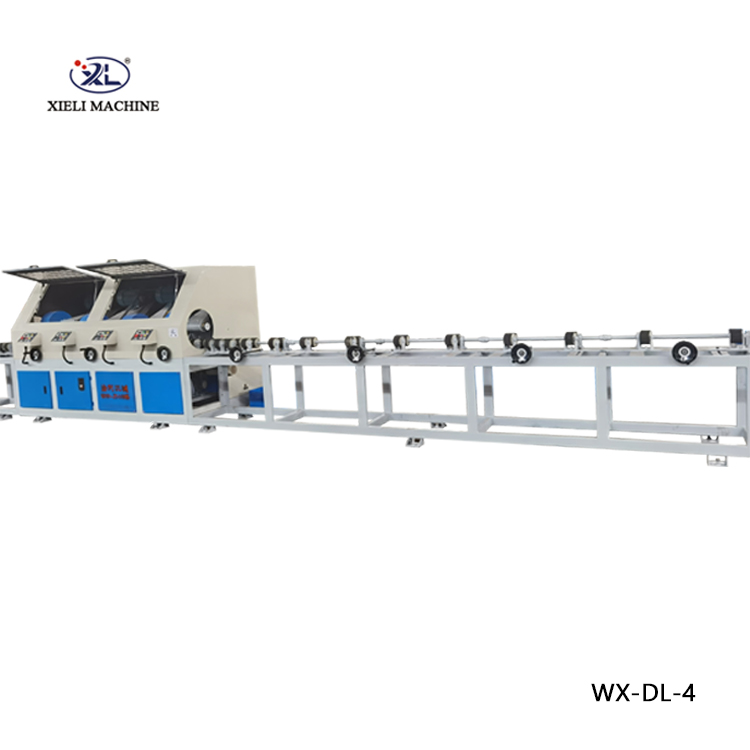

oem through feed centerless grinder

Ensuring Quality through OEM Standards

Quality control is paramount in the manufacturing industry, especially for components that require precise tolerances. OEMs adhere to strict quality standards in the production of feed centerless grinders, ensuring that each machine is capable of delivering consistent results over time. By utilizing high-grade materials and advanced manufacturing processes, OEMs can minimize defects and enhance the longevity of their machines. This commitment to quality not only benefits the end-users in terms of operational reliability but also ensures a lower total cost of ownership.

Integration with Modern Technologies

Today's manufacturing environment is increasingly leaning towards automation and Industry 4.0 principles. OEMs are responding to this trend by integrating smart technologies into their grinders. Features such as real-time monitoring, predictive maintenance, and automation capabilities are becoming standard offerings. These technologies not only improve operational efficiency but also provide valuable data that can be used to optimize processes and improve product quality.

Conclusion

The feed centerless grinder stands as a critical tool within the manufacturing landscape, offering unparalleled efficiency and precision. Partnering with reputable OEMs can empower businesses to harness the full potential of these machines. By providing customized solutions, strict adherence to quality standards, and integration of advanced technologies, OEMs ensure that the grinding processes meet modern industry's growing demands.

In summary, the collaboration between OEMs and manufacturers underscores the significance of innovation and reliability in achieving superior production capabilities. As industries continue to evolve, the role of OEMs in feed centerless grinders will remain crucial, paving the way for future advancements in grinding technology.