OEM Steel Pipe Internal Grinding Machine Enhancing Precision and Efficiency in Pipe Manufacturing

The manufacturing industry has seen remarkable advancements in technology over the years, and the precision of processes is more crucial than ever. One area that requires particular attention is the internal finishing of steel pipes, especially in applications where fluid dynamics play a vital role. The OEM steel pipe internal grinding machine is engineered to meet the high standards demanded in modern manufacturing, delivering precision, efficiency, and versatility.

Understanding Internal Grinding Machines

Internal grinding is a specialized machining process used to finish the inside surfaces of pipes, tubes, and other hollow components. The goal is to achieve exact dimensions, superior surface quality, and tight tolerances that are often necessary for various industrial applications, from oil and gas to aerospace. Unlike external grinding, which focuses on the outer surfaces, internal grinding machines fit inside the workpiece and are equipped with powerful grinding tools that remove material from the internal surfaces.

The Advantages of OEM Steel Pipe Internal Grinding Machines

OEM (Original Equipment Manufacturer) steel pipe internal grinding machines possess several advantages that set them apart from standard grinding equipment. One of the primary benefits is customizability. These machines can be tailored to meet the specific requirements of a manufacturer, taking into account the unique characteristics of the pipes being produced and the desired finish.

1. Precision Engineering The OEM machines are constructed using high-grade materials and cutting-edge technology, ensuring that they can deliver consistent and repeatable results. This precision is particularly vital in sectors such as oil and gas, where any defects in the pipes could lead to catastrophic failures.

2. Efficiency In today’s fast-paced manufacturing environment, time is often equated with money. OEM internal grinding machines are designed to operate at high speeds while maintaining accuracy, significantly reducing cycle times. This increase in efficiency allows manufacturers to produce more finished products in a shorter timeframe, contributing to a healthier bottom line.

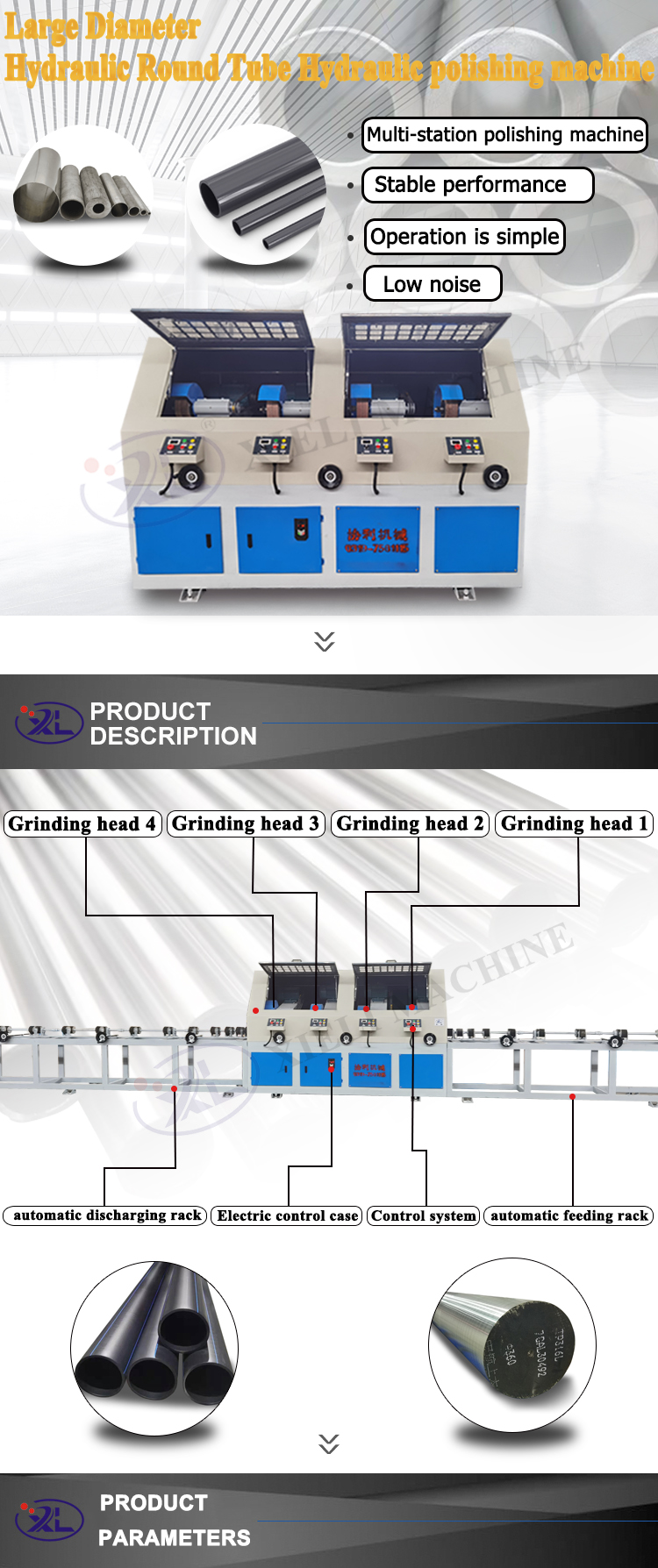

oem steel pipe internal grinding machine

3. Versatility These machines can handle a variety of pipe dimensions and materials. Whether it’s stainless steel, carbon steel, or high-alloy pipes, OEM internal grinding machines are versatile enough to adapt to different specifications. This flexibility enables manufacturers to expand their product lines without the need for multiple specialized machines.

4. User-Friendly Operation Modern OEM grinding machines often come equipped with advanced control systems that simplify operation. User-friendly interfaces allow operators to input precise settings quickly, while automated features reduce the potential for human error. This ease of use can lead to shorter training times and smoother production processes.

5. Enhanced Surface Finishing The quality of the internal surface plays a critical role in how fluids flow through pipes. Poorly finished interiors can lead to turbulence, increasing friction and reducing efficiency. OEM internal grinding machines are capable of achieving superior surface finishes that optimize flow characteristics, making them ideal for high-performance applications.

The Future of Steel Pipe Manufacturing

As industries continue to evolve and demand for high-quality steel pipes grows, the need for sophisticated internal grinding solutions becomes clear. The OEM steel pipe internal grinding machine represents the future of pipe manufacturing, merging technology with engineering precision.

Looking ahead, manufacturers increasingly incorporate automation and smart technology into their production lines. This includes the integration of artificial intelligence for predictive maintenance, which can mitigate downtime and ensure consistent output quality. Additionally, advancements in grinding wheel technologies and coolant systems are likely to further enhance performance and efficiency.

Conclusion

In summary, the OEM steel pipe internal grinding machine is a vital asset for manufacturers aiming to thrive in competitive markets. With its ability to deliver precision, boost efficiency, and provide versatility, this machine stands as a cornerstone of modern pipe production. As technology continues to advance, the adoption of these machines will undoubtedly play a critical role in enhancing the overall quality and performance of steel pipes, ensuring they meet the rigorous demands of various industries. The commitment to precision and efficiency in manufacturing is not just an operational necessity; it is a pathway to innovation and success.