The Importance of OEM SS Tube Polishing Machines in Modern Manufacturing

In the realm of manufacturing, precision and quality are paramount. This is particularly true for stainless steel (SS) tubes, which are widely utilized across various industries, including automotive, aerospace, construction, and pharmaceuticals. One crucial tool in the production of high-quality stainless steel tubes is the Original Equipment Manufacturer (OEM) SS Tube Polishing Machine. This article delves into the importance of these machines, their mechanisms, and their benefits to manufacturers.

Understanding the Role of SS Tube Polishing Machines

Stainless steel tubes must meet stringent quality standards in both their structural integrity and appearance. Surface finish plays a critical role in these applications, as it not only affects aesthetic appeal but also influences resistance to corrosion, wear, and soot deposit buildup. OEM SS tube polishing machines are specifically designed to provide a consistent, high-quality finish on stainless steel tubes. They achieve this through specialized polishing techniques that enhance the tube's surface, improving its overall durability and lifespan.

Features of OEM SS Tube Polishing Machines

1. Customization OEM machines are tailored to meet the specific needs of a manufacturer. This customization could include the diameter of the tubes, the desired level of surface finish, and the production speed. This adaptability allows businesses to streamline their manufacturing processes and maintain high standards for their products.

2. Precision Engineering The design of OEM SS tube polishing machines incorporates advanced technology that ensures precision in every facet of the polishing process. With features like automatic feeding and angle adjustment, these machines can achieve uniform finishes across all tubes, eliminating inconsistencies that may occur with manual polishing.

3. Automation Many modern OEM machines utilize automation to improve efficiency and reduce labor costs. Automated systems can monitor the entire polishing process, ensuring that each tube receives the right amount of polish while minimizing the risk of human error. This leads to higher throughput and improved productivity.

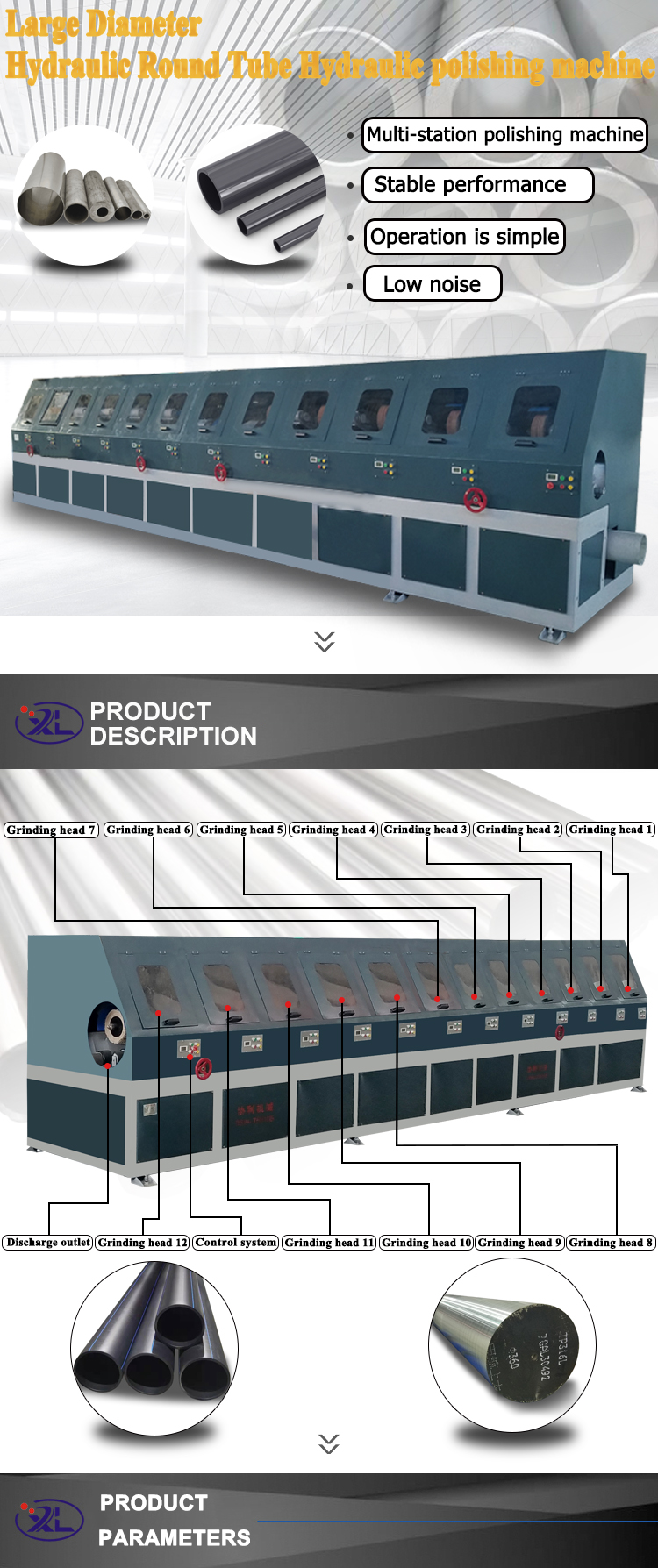

oem ss tube polishing machine

4. Versatility OEM SS tube polishing machines are versatile and can work with a variety of tube sizes and shapes. This versatility allows manufacturers to use a single machine for different products, reducing the need for multiple machines and thus saving on equipment costs.

Benefits of Using OEM SS Tube Polishing Machines

1. Improved Product Quality By providing a consistent and high-quality finish, these polishing machines significantly enhance the overall quality of the final product. Products that undergo thorough polishing are not only visually appealing but are also more resistant to corrosion, which is crucial for their longevity in service.

2. Increased Production Efficiency With their ability to automate processes and maintain consistency, OEM SS tube polishing machines help manufacturers achieve higher production rates. This efficiency is vital in competitive markets where time-to-market can dictate success.

3. Cost-Effectiveness Although the initial investment in OEM machines might be high, the long-term savings make them a cost-effective choice. Reduced labor costs, lower material waste, and fewer rejections due to poor quality contribute to better profit margins over time.

4. Environmental Impact Many modern polishing machines are designed with energy efficiency in mind. Reduced energy consumption and less material waste mean that manufacturers can operate more sustainably, which is increasingly important in today’s environmentally conscious market.

Conclusion

In conclusion, OEM SS tube polishing machines are indispensable assets for manufacturers dealing with stainless steel tubes. Their precision engineering, customizable features, and automation capabilities not only enhance product quality and increase production efficiency but also contribute to cost savings and reduced environmental impact. As industries continue to evolve and competitiveness increases, investing in advanced polishing technology will be crucial for manufacturers aiming to lead the market. The future of stainless steel tube production is bright, with OEM SS tube polishing machines at the forefront, driving innovation and excellence in the industry.