The OEM Scarlo Centerless Grinder Precision and Efficiency in Manufacturing

In the world of manufacturing, the demand for precision and efficiency is ever-increasing. Among the numerous tools designed to meet these demands, the OEM Scarlo Centerless Grinder stands out as an exemplary choice for businesses seeking to enhance their production processes. This article explores the features, benefits, and applications of the OEM Scarlo Centerless Grinder, illustrating why it’s a preferred option for many industries.

Understanding Centerless Grinding

Centerless grinding is a method of shaping the outside of an object. Unlike conventional grinding processes, it does not require the workpiece to be mounted between centers but instead relies on a setup that allows the workpiece to be supported on its own. This technique offers several advantages, including higher production rates, reduced part handling, and the ability to grind a wide range of shapes and sizes.

Key Features of the OEM Scarlo Centerless Grinder

1. Advanced Technology The OEM Scarlo Centerless Grinder is equipped with state-of-the-art technology that ensures high levels of accuracy and repeatability. Its intelligent control systems allow for precise adjustments of the grinding parameters, enabling operators to achieve optimal results.

2. Robust Construction Designed for durability, the grinder is built with high-quality materials that resist wear and tear. This robustness translates into reduced maintenance costs and extended machine life, offering manufacturers a solid return on their investment.

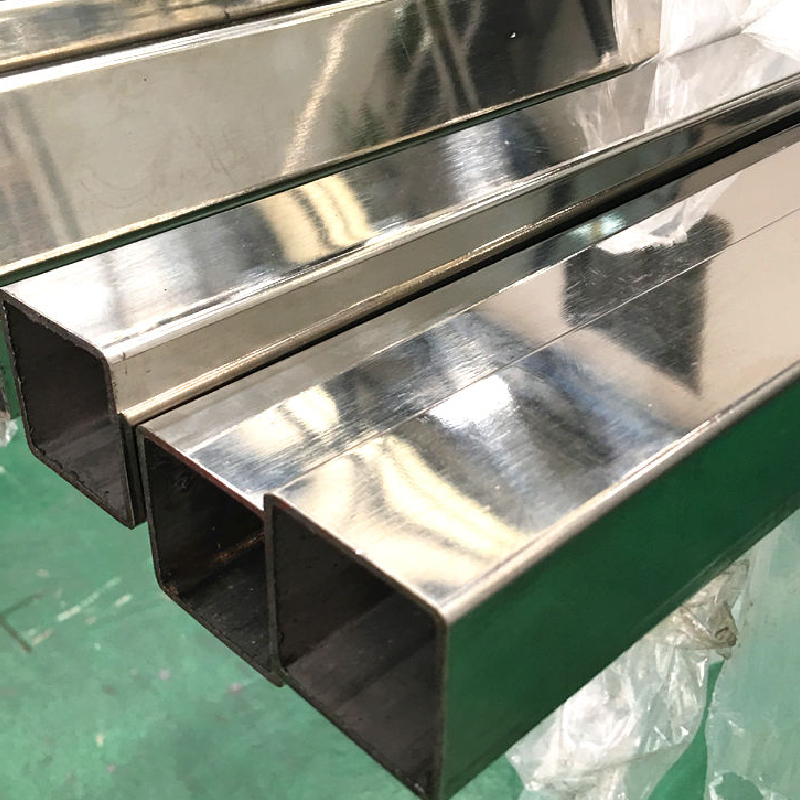

3. Versatility One of the standout features of the OEM Scarlo Centerless Grinder is its versatility. It can handle a wide array of materials, including metals, plastics, and composites, making it suitable for various industries such as automotive, aerospace, and medical manufacturing.

4. User-Friendly Interface The grinder is designed with an intuitive user interface, allowing operators to quickly learn how to use the machine effectively. This ease of use minimizes downtime and maximizes productivity, as employees can focus more on production and less on troubleshooting.

oem scarlo centerless grinder

5. Precision Engineering The heart of the OEM Scarlo Centerless Grinder lies in its ability to produce parts to exact specifications. Achieving tolerances of microns is possible, making it ideal for applications where precision is crucial, such as in the manufacturing of shafts, pins, and tubes.

Benefits of Using the OEM Scarlo Centerless Grinder

The adoption of the OEM Scarlo Centerless Grinder in manufacturing processes brings a host of benefits

- Increased Productivity With its efficient grinding process, manufacturers can produce more parts in less time, significantly enhancing productivity levels.

- Cost-Effectiveness The combination of reduced labor costs, minimized material waste, and extended equipment lifespan makes this grinder a cost-effective solution for businesses.

- Improved Quality Control The ability to maintain tight tolerances improves the overall quality of the products manufactured, thus reducing the likelihood of defects and enhancing customer satisfaction.

- Enhanced Competitive Advantage By incorporating cutting-edge technology and efficient production methods, businesses can stay ahead of competitors in the fast-paced manufacturing landscape.

Conclusion

In conclusion, the OEM Scarlo Centerless Grinder offers manufacturers a powerful tool that embodies precision, efficiency, and versatility. By investing in such advanced machinery, businesses can streamline their production processes, produce high-quality components, and ultimately drive growth in an increasingly competitive market. As industries continue to evolve, tools like the Scarlo Centerless Grinder will play a critical role in shaping the future of manufacturing.