The Importance of OEM Pipe End Grinding Machines in Modern Manufacturing

In the realm of manufacturing, precision and quality control are paramount, especially when it comes to metal components such as pipes. One of the critical processes in ensuring the highest standards in pipe fabrication is the end grinding process. An Original Equipment Manufacturer (OEM) pipe end grinding machine plays a crucial role in this aspect, providing advanced capabilities that enhance product quality and production efficiency.

Overview of Pipe End Grinding

Pipe end grinding is a process designed to smooth and finish the edges of pipes. This process is essential for various reasons — it ensures that pipes fit together seamlessly during assembly, improves the aesthetics of the product, and reduces the risk of defects that could lead to failures in applications. The end grinding process can vary based on the material of the pipes, their intended use, and the specifications required by the project.

Given the range of applications that pipes serve, from construction to oil and gas, the requirements for each application can be drastically different. Thus, having precise and customizable grinding solutions becomes an integral part of the manufacturing process.

What is an OEM Pipe End Grinding Machine?

An OEM pipe end grinding machine is a specialized piece of equipment designed specifically for grinding the ends of pipes. Unlike standard grinding machines, OEM machines are tailored to meet the specific needs of manufacturers, providing them with bespoke solutions that optimize performance and efficiency.

These machines typically feature advanced technology that allows for high-speed grinding to achieve a smooth finish while also maintaining the pipe's dimensions

. OEM machines can be designed to handle various pipe sizes and types, making them a versatile option in any manufacturing facility.Key Features and Benefits

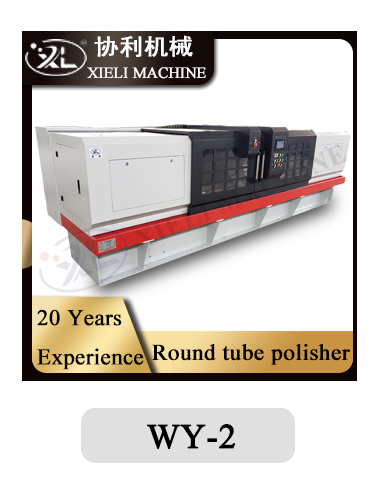

oem pipe end grinding machine

One of the standout features of modern OEM pipe end grinding machines is their automation capabilities. Many machines come equipped with computer numerical control (CNC) systems, enabling precision in the grinding process. This automation reduces human error, increases consistency, and ensures that each pipe end meets the specified tolerances.

Moreover, the design of OEM machines often includes ergonomic considerations. Operators can work comfortably and efficiently, reducing the risk of fatigue or injury. This consideration is increasingly important in today's manufacturing environments, where safety and well-being are prioritized.

Another significant advantage of using an OEM pipe end grinding machine is the potential for increased production rates. With improved efficiency and faster processing times, manufacturers can produce larger quantities of finished pipes, catering to both regular orders and urgent demands without sacrificing quality.

Quality Control and Customization

Quality control is a crucial aspect of the manufacturing process, and pipe end grinding machines contribute significantly to this. The incorporation of sensors and measurement tools in modern OEM machines allows for real-time monitoring of the grinding process. Any deviations from the standard can be immediately flagged, enabling quick corrective actions. This capability is particularly beneficial in industries where specifications are strict, and any imperfections can lead to catastrophic failures.

Moreover, OEM pipe end grinding machines can be customized to meet specific production needs. Manufacturers can select different grinding tools, speeds, and processes based on the type of material being worked on—whether steel, aluminum, or other alloys. This level of customization ensures that the machines can adapt to a broad array of applications, from large-scale industrial projects to smaller, specialized tasks.

Conclusion

In conclusion, OEM pipe end grinding machines are essential tools in modern manufacturing, significantly impacting the quality and consistency of pipe production. Their advanced features, including automation, quality control mechanisms, and customization options, provide manufacturers with the capability to meet demanding industry standards. As industries continue to evolve and require more precise and high-quality outputs, the importance of these machines will only grow, further solidifying their place in the future of manufacturing. Investing in an OEM pipe end grinding machine is not just a step towards efficiency; it is a strategic move towards ensuring long-term competitiveness in an increasingly complex market.