The Importance of OEM Internal Centerless Grinding Machines in Precision Manufacturing

In the world of precision manufacturing, the quest for quality and efficiency often leads companies to explore advanced machinery that can enhance production capabilities. Among these, OEM (Original Equipment Manufacturer) internal centerless grinding machines have emerged as a pivotal technology for achieving superior results in the processing of various components. These machines are particularly valued for their ability to perform high-precision grinding without the need for traditional clamping and fixturing, thereby streamlining manufacturing processes.

What is Centerless Grinding?

Centerless grinding is a machining process that uses abrasive cutting to remove materials from a workpiece. Unlike traditional grinding methods that require the workpiece to be clamped between centers, centerless grinding operates on the principle of supporting the workpiece on the grinding wheel, with a regulating wheel controlling its rotation and feed. This method provides numerous advantages, including higher production rates, improved accuracy, and reduced operational costs.

OEM internal centerless grinding machines are specifically designed to grind the inside diameters of cylindrical components. They feature a unique configuration that allows for the efficient removal of material from the internal surfaces while maintaining tight tolerances. This capability is essential for industries where precision and the quality of internal dimensions are critical, such as automotive, aerospace, and medical device manufacturing.

Advantages of Using OEM Internal Centerless Grinding Machines

1. High Precision and Tolerance One of the most significant advantages of OEM internal centerless grinding machines is their ability to achieve high precision. These machines can produce components with diameters as tight as a few microns, making them ideal for applications that demand exact specifications.

2. Increased Productivity The design of internal centerless grinding machines allows for rapid material removal and quick setup times. This translates to higher throughput, enabling manufacturers to meet production demands efficiently.

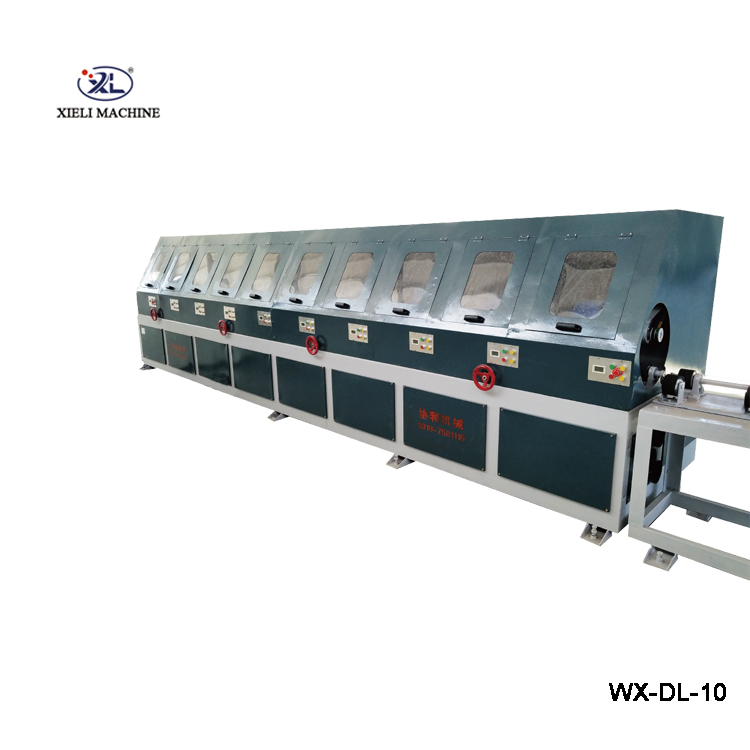

oem internal centerless grinding machine

3. Reduced Setup and Operation Costs Traditional grinding methods often involve complex setups and fixturing, which can be time-consuming and costly. Centerless grinding machines eliminate much of this overhead by allowing for uninterrupted grinding processes, ultimately saving time and resources.

4. Versatility OEM internal centerless grinding machines are capable of grinding a wide range of materials, including metals, plastics, and composites. This versatility makes them an essential tool for manufacturers looking to process diverse materials without great investment in specialized equipment.

5. Improved Surface Finish The precision grinding process inherent in centerless grinding tends to produce superior surface finishes. This characteristic is vital for components that require enhanced aesthetic qualities or precise fitting against other parts.

Applications of OEM Internal Centerless Grinding Machines

OEM internal centerless grinding machines find applications across various industries. In the automotive sector, they are commonly used to grind components such as fuel injectors, valve guides, and bearings. The aerospace industry utilizes these machines for producing critical engine parts and components requiring stringent quality controls. Similarly, in the medical field, they are indispensable for manufacturing precision instruments and implants.

Conclusion

The adoption of OEM internal centerless grinding machines marks a significant advancement in precision manufacturing. By offering unmatched accuracy, efficiency, and versatility, these machines play a crucial role in enhancing production processes across multiple industries. As competition intensifies and the demand for high-quality components increases, investing in advanced machining technologies like internal centerless grinding will be essential for manufacturers aiming to stay ahead in the market. Utilizing these machines not only simplifies operations but also positions companies for long-term success in an increasingly competitive landscape.