Exploring the OEM Infeed Centerless Grinder Enhancing Precision and Efficiency

In the manufacturing industry, precision and efficiency are paramount, especially when it comes to grinding processes. Among the various types of grinding machines, the centerless grinder stands out for its ability to handle a wide range of materials and achieve high accuracy. An Original Equipment Manufacturer (OEM) infeed centerless grinder is particularly noteworthy, as it not only enhances the grinding process but also contributes significantly to overall production efficiency.

What is a Centerless Grinder?

A centerless grinder is a machine tool used for grinding cylindrical parts without the use of centers. Unlike traditional grinders, where the workpiece is held between centers, a centerless grinder employs a different mechanism. It utilizes a rotary grinding wheel and a drive mechanism to maintain the workpiece in place. This design allows for continuous feed of the workpiece through the grinding zone, which can significantly increase productivity and reduce operational costs.

The Role of OEM in Manufacturing

OEMs play a crucial role in the manufacturing landscape. They design and produce equipment tailored to specific production needs and industry standards. Infeed centerless grinders manufactured by OEMs are designed to deliver precision, reliability, and efficiency. These machines are typically engineered with advanced technology to meet the high demands of various industries, including automotive, aerospace, and medical device manufacturing.

Advantages of Infeed Centerless Grinding

1. High Precision One of the most significant benefits of using an OEM infeed centerless grinder is the ability to achieve tight tolerances. The grinding process can be adjusted to ensure that parts are ground to exact specifications, which is critical in industries where precision is non-negotiable.

2. Enhanced Productivity Infeed centerless grinders allow for continuous operation, which means that parts can be fed into the machine without interruption. This leads to shorter cycle times and higher throughput, enabling manufacturers to meet high production demands efficiently.

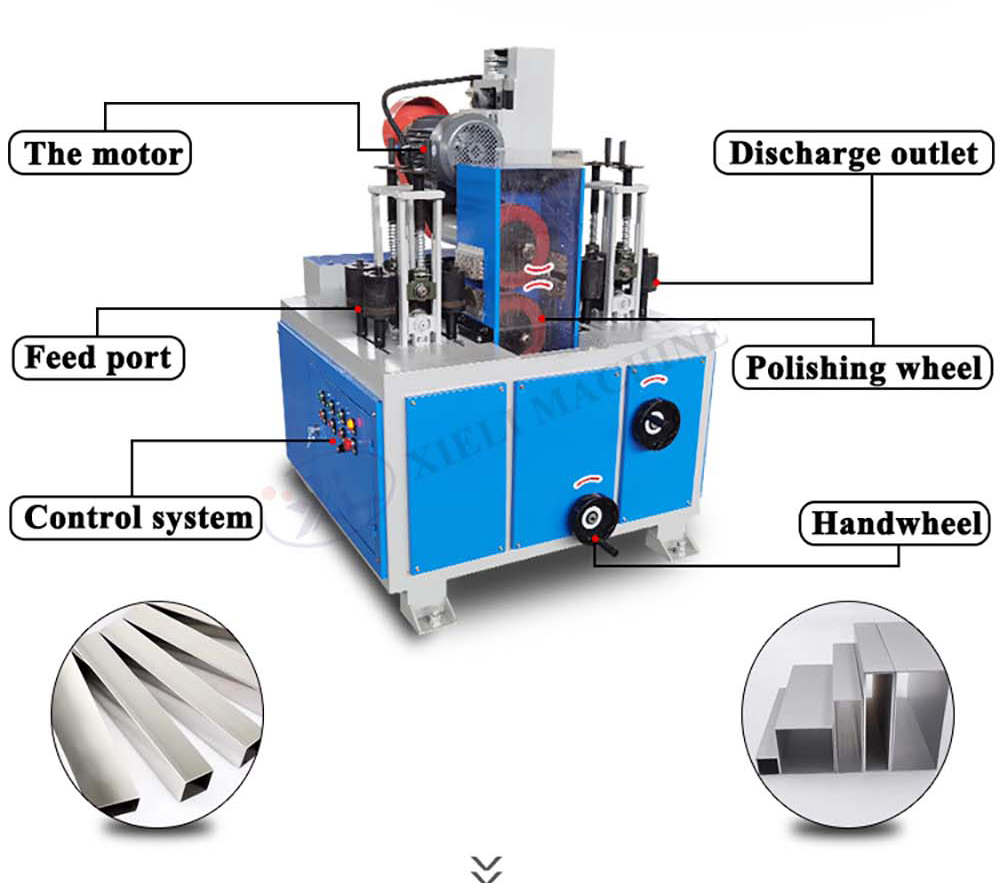

oem infeed centerless grinder

3. Versatility OEM centerless grinders are designed to handle a variety of materials, including steel, aluminum, and composites. This versatility allows manufacturers to use the same equipment for different projects, thus reducing the need for multiple machines and the associated costs.

4. Minimized Setup Time With automated features and user-friendly controls, OEM infeed centerless grinders minimize setup and changeover times. This flexibility is crucial for companies that operate in a dynamic manufacturing environment where production part numbers frequently change.

5. Improved Surface Finish The grinding process used in centerless grinders results in superior surface finish quality compared to other methods. The consistent and repeatable nature of the machining process ensures that parts meet aesthetic and functional requirements.

Technological Innovations in OEM Centerless Grinders

Modern OEM infeed centerless grinders incorporate advanced technologies such as CNC (Computer Numerical Control) systems, which allow for precise control over grinding parameters. Innovations such as adaptive grinding technology help optimize the grinding process in real-time, ensuring that fluctuations in material properties or part dimensions do not compromise the quality of the finished product.

Moreover, many OEMs are embracing automation and smart manufacturing principles. Integrating robotics for part handling and real-time monitoring systems enhances the capability of infeed centerless grinders, further improving efficiency and reducing labor costs.

Conclusion

An OEM infeed centerless grinder is an essential piece of equipment in modern manufacturing, offering unparalleled precision, efficiency, and versatility. As industries continue to evolve and demand higher standards for quality and productivity, the importance of advanced grinding technologies, like those found in centerless grinders, will undoubtedly grow. By investing in such technology, manufacturers can ensure they remain competitive in an increasingly crowded market, driving both innovation and economic success. Through continuous improvements and growing capabilities, OEMs will continue to shape the future of precision manufacturing, making infeed centerless grinders a vital asset in any sophisticated production environment.