Exploring the OEM DIY Centerless Grinder A Guide for Enthusiasts

In the world of manufacturing and metalworking, the ability to produce precision components is paramount. Among the tools that aid in these endeavors is the centerless grinder, a machine known for its efficiency and effectiveness in achieving high tolerance and smooth finishes. With the rise of DIY culture and aftermarket modifications, many enthusiasts are exploring OEM (Original Equipment Manufacturer) options to build or enhance their own centerless grinders. This article delves into the essentials of OEM DIY centerless grinders, their advantages, and key considerations for aspiring builders.

Understanding Centerless Grinding

Centerless grinding is a machining process that involves the grinding of cylindrical workpieces without requiring the workpiece to be mechanically centered. This method has notable advantages, including the capacity to handle high volumes of parts rapidly and accurately. It relies on a setup that includes a grinding wheel, a regulating wheel, and a workpiece support system, allowing for continuous feeding of parts, which enhances productivity.

The Appeal of OEM Parts for DIY Centerless Grinders

The trend toward using OEM parts for building a DIY centerless grinder lies in the quality and precision these components offer. OEM parts are manufactured to meet specific standards and are rigorously tested for performance, making them a reliable choice for anyone looking to create a custom machine that operates efficiently. Here are some reasons why enthusiasts lean towards OEM components

1. Consistency and Reliability OEM parts are designed to fit perfectly with one another, minimizing the chances of misalignment and improving the overall performance of the grinder.

2. Quality Assurance By using parts manufactured by reputable brands, builders can rest assured that their tool will not only perform optimally but also endure the rigors of heavy usage.

3. Expert Support Many OEM manufacturers provide extensive documentation and customer support, aiding DIY builders in the assembly and maintenance of their grinders.

Key Components of a Centerless Grinder

When building your own centerless grinder, certain components deserve particular attention

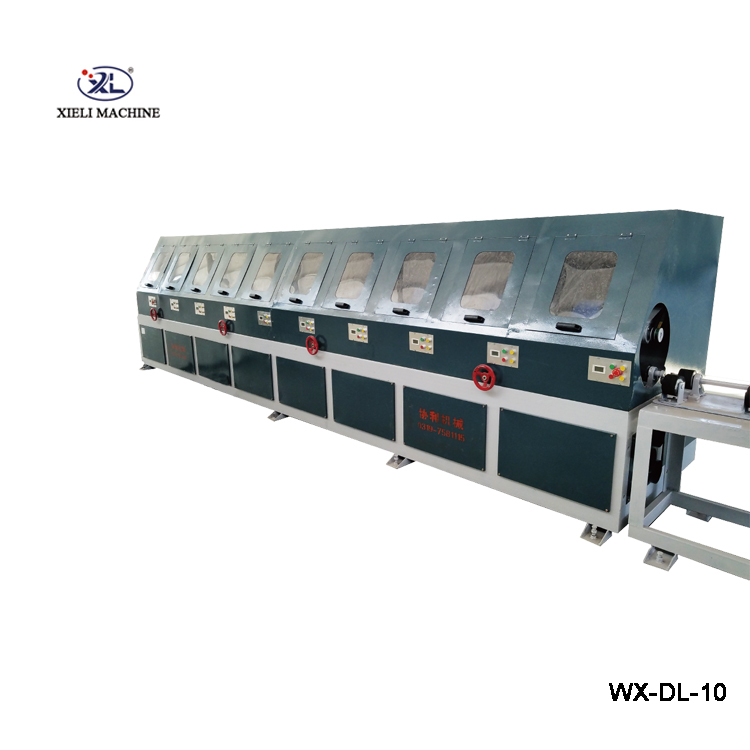

oem diy centerless grinder

- Grinding Wheel Selecting the right grinding wheel is crucial for achieving the desired surface finish and dimensional tolerances. Wheels come in various materials and grits, catering to different types of metals and applications.

- Regulating Wheel This wheel controls the speed at which the workpiece is fed into the grinding zone. The choice of the regulating wheel affects the overall grinding process and should match the specifications of the grinding wheel.

- Workpiece Supports and Holding Fixtures Accurate alignment and stability are vital for optimal grinding performance. Custom fixtures may need to be designed to cater to the specific dimensions and weights of the workpieces being processed.

- Motor and Drive System The motor should be powerful enough to operate both the grinding and regulating wheels efficiently while offering adjustable speeds for versatility.

Considerations for DIY Construction

Before diving into building a DIY centerless grinder, there are several factors you should consider

- Space and Layout Ensure you have sufficient space in your workshop to accommodate the grinder, with necessary allowances for safety and ease of access.

- Skill Level While DIY projects can be rewarding, they can also be complex. Evaluate your own skill level and consider seeking guidance or collaborating with experienced machinists if needed.

- Safety Measures Like any machine tool, a centerless grinder poses inherent risks. Proper guards, dust collection systems, and safety protocols should be established to ensure safe operations.

Conclusion

The OEM DIY centerless grinder embodies a fusion of precision engineering and personal creativity. By using high-quality OEM parts, builders can develop robust grinding machines that cater to their specific requirements. Whether you’re enhancing an existing setup or embarking on a new project, the journey of creating a custom centerless grinder holds the promise of improved capabilities in your metalworking endeavors. With careful planning and execution, your DIY grinder can become a valuable asset in achieving unparalleled workmanship and cutting-edge precision.