The Role of OEM Bar Polishing Machines in Modern Manufacturing

In the fast-paced world of modern manufacturing, precision and quality are paramount. Among the essential tools that contribute to achieving high-quality finishes in metalworking, OEM (Original Equipment Manufacturer) bar polishing machines have gained prominence. This article explores the significance of these machines, their operational mechanics, and their impact on various industries.

What is an OEM Bar Polishing Machine?

An OEM bar polishing machine is specifically designed for the polishing and finishing of metal bars and similar products. These machines can efficiently remove surface imperfections, enhance shine, and prepare materials for further processing. By utilizing custom parts and tailored designs that meet specific manufacturing requirements, OEM bar polishing machines ensure that businesses can achieve their desired quality standards.

Key Features

1. Automation Many modern OEM bar polishing machines are equipped with advanced automation features, enabling them to operate with minimal human intervention. This not only increases productivity but also ensures consistent quality and reduces the risk of human error.

2. Adjustable Parameters The ability to adjust parameters such as speed, pressure, and polishing media allows manufacturers to customize the polishing process according to the material type and desired finish. This flexibility is crucial for achieving various surface qualities, from matte to mirror finishes.

3. Efficiency OEM machines are designed for high throughput. They can process multiple bars simultaneously, greatly reducing production time compared to manual polishing methods. This efficiency is vital in industries where high volume and swift turnaround are essential.

4. Durability Built with robust materials, OEM bar polishing machines are designed to withstand the rigors of industrial use. This durability translates to lower maintenance costs and longer operational lifespans, benefiting manufacturers in the long run.

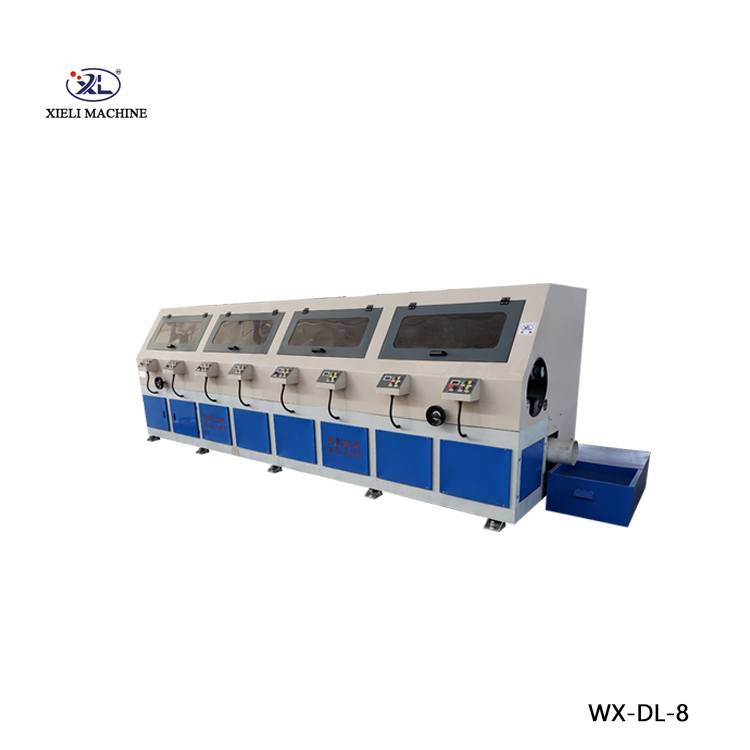

oem bar polishing machine

Applications in Various Industries

OEM bar polishing machines are widely used across many sectors, each requiring specific finishing capabilities

- Automotive Industry In the automotive sector, polished bars are integral for components like suspension systems, where surface finish directly affects performance and safety. These machines ensure that every part meets stringent quality standards.

- Aerospace The aerospace industry demands impeccable quality and precision. OEM polishing machines are used to finish component bars that are critical to aircraft performance and safety, providing a finish that can withstand extreme conditions.

- Medical Devices In the manufacturing of medical equipment, polished surfaces are not just about aesthetics. Smooth finishes are essential to avoid bacterial growth and ensure safety. OEM polishing machines help manufacturers comply with stringent health regulations.

- Construction Components used in construction, such as structural bars, benefit from polishing which enhances appearance and resistance to corrosion. This not only extends the life of the materials but also meets the aesthetic demands of modern architecture.

Conclusion

In conclusion, OEM bar polishing machines are invaluable tools in contemporary manufacturing, enhancing both efficiency and quality. As industries continue to strive for perfection in product finish, the role of such specialized equipment becomes increasingly significant. Manufacturers that invest in advanced OEM bar polishing machines position themselves competitively in the market, ensuring product excellence and customer satisfaction.

By integrating these machines into their operations, businesses not only improve their manufacturing processes but also foster innovation and growth in their respective sectors. As we look toward the future, the importance of precision engineering will only amplify, and OEM bar polishing machines will remain at the forefront of this evolution.