The Importance of OEM Acme Centerless Grinders in Precision Manufacturing

In the realm of precision manufacturing, the role of high-quality machinery cannot be overstated. Among these, the OEM Acme Centerless Grinder stands out as a pivotal piece of equipment that significantly enhances productivity and accuracy. Centerless grinding is a machining process that permits the grinding of cylindrical workpieces without the need for supportive fixtures. This unique advantage greatly increases efficiency and precision, making it a favored choice in various industrial applications.

The Importance of OEM Acme Centerless Grinders in Precision Manufacturing

Moreover, the design of the OEM Acme Centerless Grinder emphasizes user-friendliness. Operators can easily adjust the machinery to accommodate different workpiece sizes and shapes, which streamlines the production process. This flexibility not only reduces setup times but also increases throughput, allowing manufacturers to produce higher volumes without compromising quality.

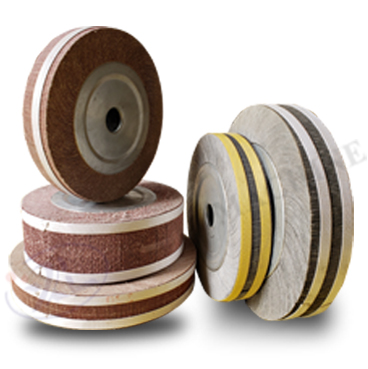

oem acme centerless grinder

The durability and reliability of the Acme Centerless Grinder further set it apart. Built with high-grade materials and advanced engineering, these grinders are designed to withstand the rigors of continuous operation. This robustness ensures minimal downtime, leading to greater operational efficiency and cost savings over the lifespan of the machinery. Regular maintenance and the availability of OEM replacement parts further contribute to the longevity of the grinder, making it a wise investment for any manufacturing operation.

In addition to performance, the environmental considerations of machining processes are becoming increasingly important. Acme’s commitment to innovative and sustainable practices is evident in the design of their centerless grinders, which are engineered to minimize waste and energy consumption. By opting for OEM equipment like the Acme Centerless Grinder, manufacturers can not only enhance their operational efficiency but also align with modern sustainability practices.

In conclusion, the OEM Acme Centerless Grinder plays a critical role in the landscape of precision manufacturing. Its combination of flexibility, precision, durability, and sustainability makes it an indispensable tool for modern manufacturers aiming to achieve high-quality results. As industries continue to evolve and demand more sophisticated machining solutions, investing in a reliable centerless grinder like those offered by Acme is essential for staying competitive and meeting customer needs. Therefore, organizations looking to enhance their manufacturing capabilities should consider incorporating OEM Acme Centerless Grinders into their production processes.