The Evolution of OEM Pipe Polishing Machines

In the realm of manufacturing and metalworking, the pursuit of perfection often lies in the finer details. An essential aspect of this is the surface finish of products, particularly in industries where aesthetics and durability are paramount. One of the critical innovations aiding this endeavor is the OEM pipe polishing machine, designed to enhance the quality of pipes used in various applications.

OEM, or Original Equipment Manufacturer, refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the case of pipe polishing machines, OEMs provide specialized machines optimized for specific applications, ensuring that the end product meets or surpasses industrial standards.

The Evolution of OEM Pipe Polishing Machines

Modern OEM pipe polishing machines are equipped with advanced technology to provide superior polishing capabilities. Automated systems often incorporate intelligent controls and feedback mechanisms to adjust the polishing process in real-time based on the type of material and desired finish. This automation increases efficiency, reduces human error, and ensures consistency across large batches of products.

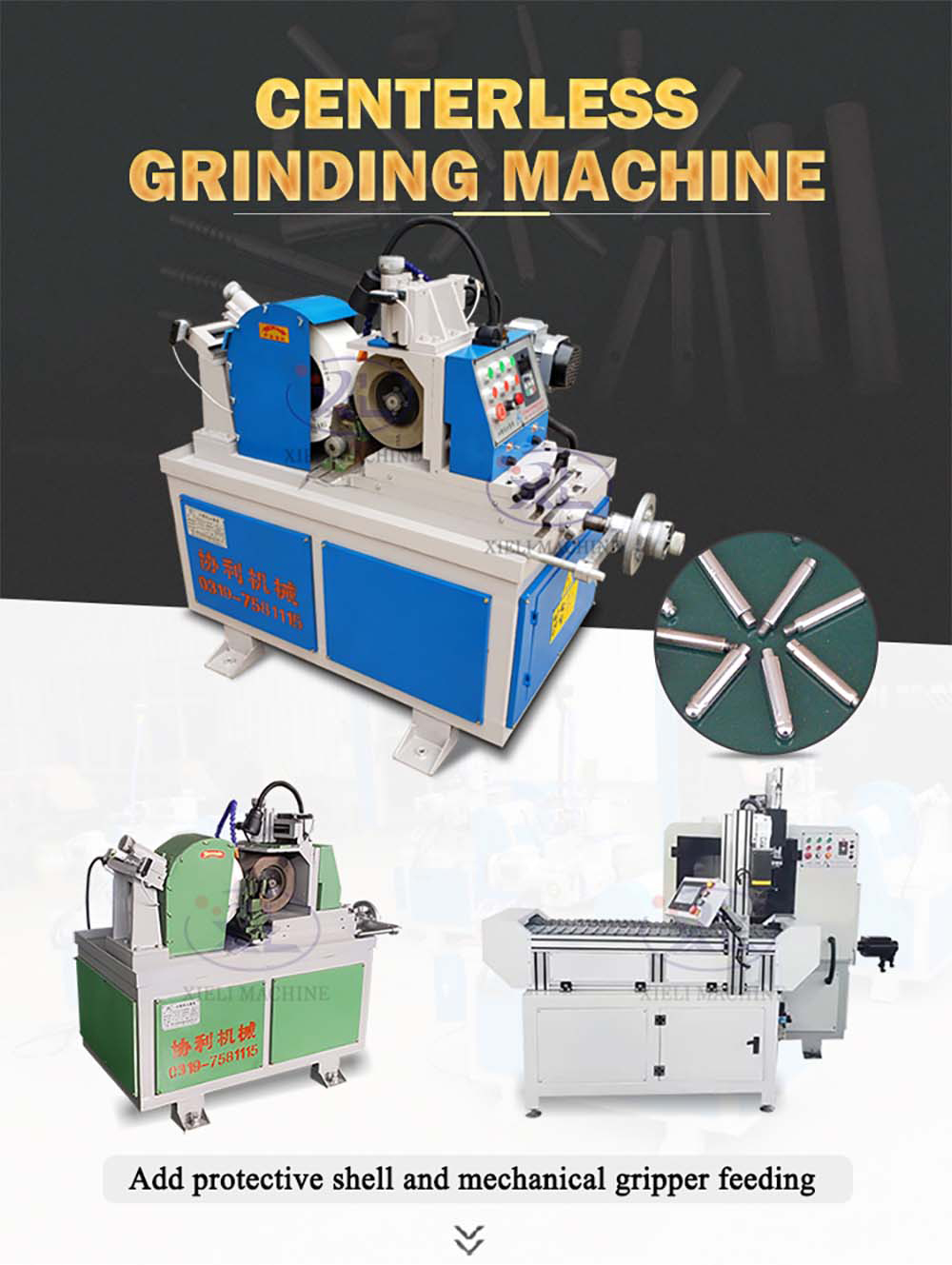

oem pipe polishing machine

There are various techniques used in pipe polishing, including mechanical polishing, electro-polishing, and abrasive polishing. Mechanical polishing involves the use of rotary tools and abrasive materials to achieve the desired surface quality. Electro-polishing, on the other hand, uses an electrolytic process to remove the outer layer of metal, resulting in a smooth and shiny finish. The choice of technique depends on the material of the pipe, the required finish quality, and the operational cost.

Choosing the right OEM pipe polishing machine can significantly enhance production efficiency. Factors such as the machine's speed, its ability to handle different pipe sizes and materials, and the type of polishing method it employs are critical in making an informed decision. Furthermore, manufacturers must consider the machine’s maintenance requirements and the availability of spare parts, as these impact long-term operational costs.

The versatility and effectiveness of OEM pipe polishing machines not only streamline the production process but also help meet the growing demand for high-quality metal products in an increasingly competitive market. As industries evolve and new materials are introduced, the demand for innovative polishing solutions will continue to rise.

In conclusion, OEM pipe polishing machines represent a significant advancement in the quest for superior metal finishes. With their ability to automate and optimize the polishing process, these machines play a crucial role in producing high-quality pipes that meet the rigorous demands of various industries. As technology continues to evolve, we can expect even greater efficiencies and capabilities from future generations of pipe polishing machines.