The Importance of ODM Tube Polishing Machines in Modern Manufacturing

In today's competitive manufacturing landscape, the demand for high-quality finished products has never been greater. One critical aspect of this demand is the surface finish of metal components, particularly tubes. This is where the ODM tube polishing machine comes into play. These machines have revolutionized the way manufacturers approach tube polishing, ensuring consistency, efficiency, and superior quality.

What is an ODM Tube Polishing Machine?

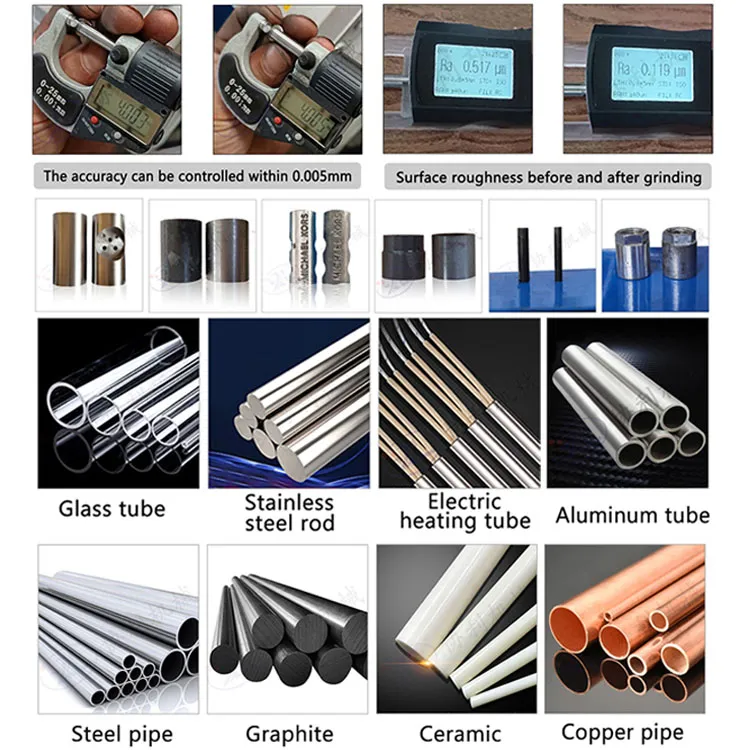

ODH stands for outer diameter, and an ODM tube polishing machine is specifically designed for polishing the outer surfaces of tubular metal products. These machines utilize advanced technology to grind, buff, and polish tubes made from various materials such as stainless steel, aluminum, and brass. The polishing process typically involves several stages, including pre-polishing, polishing, and buffing, each of which is crucial to achieving a flawless finish.

Advantages of Using ODM Tube Polishing Machines

1. Enhanced Efficiency Traditional methods of tube polishing can be labor-intensive and time-consuming. ODM tube polishing machines automate much of the process, significantly speeding up production times. This not only increases throughput but also allows manufacturers to allocate labor to other critical areas of production.

2. Consistent Quality Consistency in product quality is essential for customer satisfaction. ODM machines are designed to maintain uniform polishing standards across batches of tubes. This is particularly important in industries such as automotive and aerospace, where even the slightest imperfection can lead to product failure.

3. Flexibility Modern ODM tube polishing machines can handle a variety of tube sizes and shapes, making them highly versatile. This flexibility allows manufacturers to adapt quickly to changing market demands and produce custom tube sizes as needed.

odm tube polishing machine products

4. Reduced Waste Another significant advantage of using ODM machines is the reduction in material waste. Automated polishing minimizes the risk of human error, which can lead to damaged products. Additionally, precise polishing reduces the need for excessive material removal, preserving the integrity of the tube.

5. Higher Profit Margins With increased efficiency, consistent quality, and reduced waste, manufacturers using ODM tube polishing machines can enjoy higher profit margins. The investment in these machines often pays off quickly as production costs decrease and the quality of the final product improves.

Applications of ODM Tube Polishing Machines

ODM tube polishing machines find applications in various industries. In the automotive sector, they are used to polish exhaust pipes, chassis components, and other structural elements. The food and beverage industry also relies on polished tubes for hygiene and aesthetic purposes, ensuring that equipment meets strict regulatory standards. Moreover, in the architectural and construction sectors, polished tubes are used in railings, supports, and decorative elements, where appearance and durability are paramount.

Conclusion

The ODM tube polishing machine is an indispensable tool in modern manufacturing. As industries continue to evolve, the need for high-quality polished metallic components will only increase. Investing in advanced ODM tube polishing technology not only streamlines the manufacturing process but also enhances product quality and customer satisfaction.

In a world where precision and excellence define success, ODM tube polishing machines stand out as a crucial player in meeting the ever-growing demands of the market. By choosing these machines, manufacturers can stay ahead of the competition, ensuring that they deliver superior products efficiently and cost-effectively. As technology continues to advance, the future of tube polishing looks promising, promising even greater innovations and improvements in the coming years.