The Importance of ODM Table Top Centerless Grinders in Precision Manufacturing

In the realm of precision manufacturing, the significance of high-quality machinery cannot be overstated. One such vital piece of equipment is the ODM table top centerless grinder, a machine that plays a crucial role in ensuring accurate and efficient production processes. This article will delve into the features and advantages of this grinder, and how it enhances manufacturing capabilities.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that allows for the grinding of cylindrical parts without the need for centered mounting. This grinding technique involves placing the workpiece on the surface of a rotating wheel, which then grinds the outer diameter. The ODM table top centerless grinder is specifically designed for smaller workspaces, making it an ideal choice for precision jobs where space is limited.

Key Features of ODM Table Top Centerless Grinders

1. Compact Design One of the most significant advantages of table top centerless grinders is their compact size. The ODM model is designed to fit into tight spaces while providing high performance. This is particularly beneficial for small workshops or manufacturing plants that may have constraints on available floor space.

2. Precision Grinding ODM table top grinders are known for their precision. The grinder features advanced technology that ensures a high degree of accuracy in the grinding process. This is crucial for industries that require tight tolerances for their components, such as automotive and aerospace sectors.

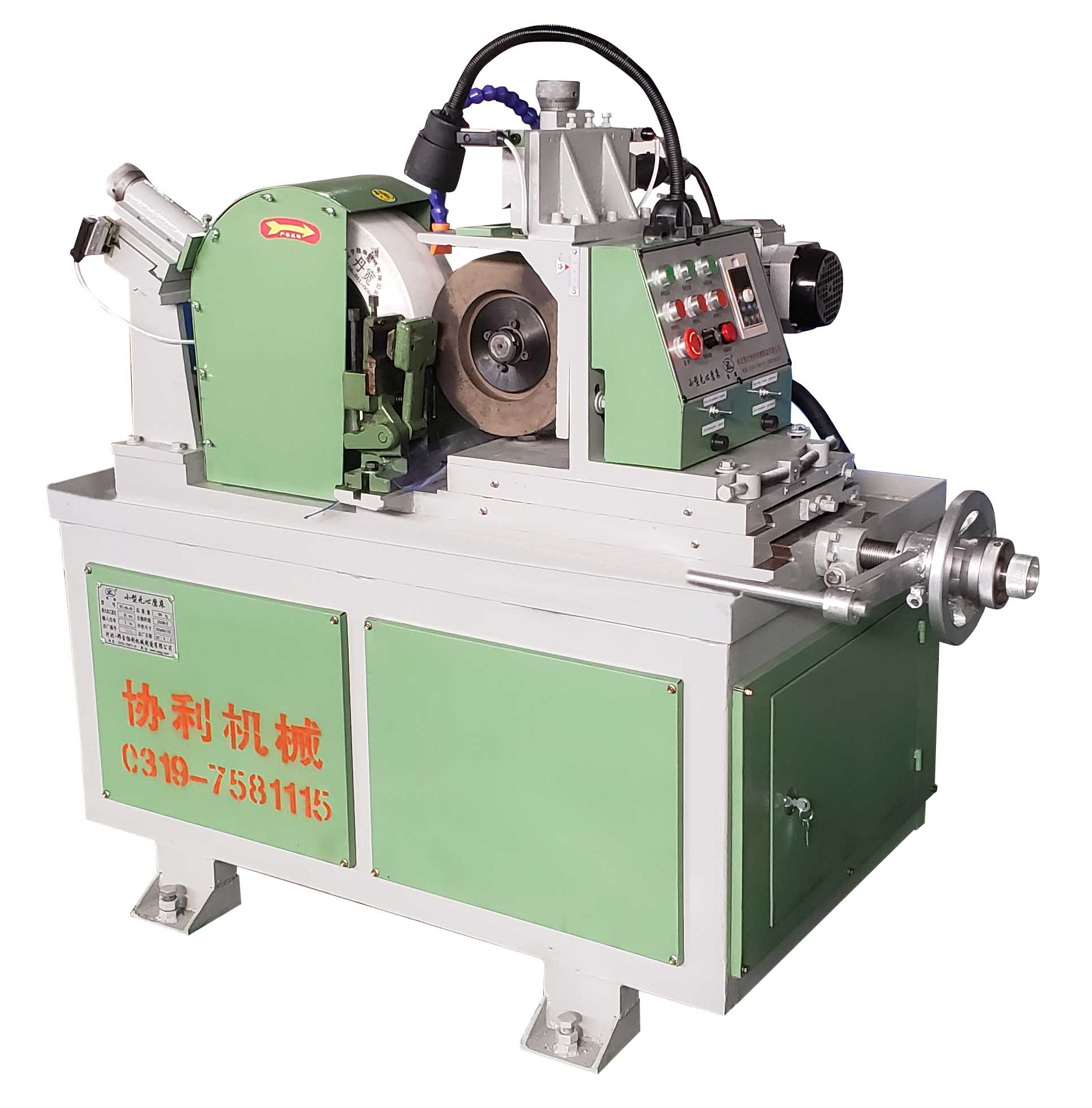

odm table top centerless grinder

3. User-Friendly Operation Ergonomically designed with the operator in mind, ODM grinders are equipped with intuitive controls and easy setup procedures. This makes them accessible for operators at various skill levels, facilitating training and improving overall productivity.

4. Versatility The versatility of ODM table top centerless grinders allows them to handle a variety of materials, including metals, plastics, and ceramics. This flexibility enables manufacturers to work on diverse projects without the need for multiple machines, thereby saving both time and costs.

5. Enhanced Efficiency The grinding process in centerless grinders is continuous, which means that multiple pieces can be worked on simultaneously. This high throughput capability leads to enhanced efficiency and reduced cycle times in production lines.

Applications in Various Industries

The uses of ODM table top centerless grinders extend across numerous industries. In medical device manufacturing, precision is paramount; these grinders help produce parts that meet stringent health standards. Similarly, in the electronics and automotive fields, where components must be manufactured with exactness, the ability to grind parts with minimal deviation can greatly influence performance and reliability.

Conclusion

The ODM table top centerless grinder epitomizes the fusion of efficiency, precision, and compact design in manufacturing technology. As industries continue to demand higher standards for their components, such machines will undoubtedly play a pivotal role in meeting those expectations. With its ability to deliver superior grinding results while accommodating the constraints of modern manufacturing spaces, the table top centerless grinder stands as a testament to the advancements in manufacturing technology efforts to drive productivity and quality in various sectors.