Exploring the ODM Stainless Tube Polishing Machine A Game Changer for Industrial Finishing

In the realm of manufacturing and industrial design, the finishing process plays a critical role in enhancing the aesthetic and functional qualities of products. One of the most significant advancements in this area is the ODM Stainless Tube Polishing Machine, which has gained prominence for its efficiency and effectiveness in polishing stainless steel tubes. This article delves into the features, benefits, and applications of this innovative machine, demonstrating why it has become a staple in various industries.

Understanding the ODM Stainless Tube Polishing Machine

The ODM Stainless Tube Polishing Machine is specifically designed for polishing stainless steel tubes, offering a solution that combines precision with speed. Tailored for both large-scale operations and smaller workshops, this machine integrates advanced technology to deliver superior polishing results. Its design ensures that it can handle a variety of tube sizes and shapes, making it versatile for different applications.

Key Features

1. High-Speed Operation One of the standout features of the ODM polishing machine is its high-speed operation. Capable of polishing at varying speeds, it significantly reduces processing time, thereby boosting productivity. This is particularly beneficial for industries that require quick turnaround times.

2. Automated Controls With user-friendly automated controls, operators can easily set parameters to achieve desired polishing results. This automation minimizes manual intervention, ensuring consistency and reducing the likelihood of human error.

3. Multiple Polishing Heads The ODM machine often comes equipped with multiple polishing heads that can be adjusted according to the specific needs of the project. This feature allows for simultaneous polishing of multiple tubes, further enhancing efficiency.

4. Dust and Waste Management The design of the machine incorporates effective dust and waste management systems, ensuring a clean working environment. This is crucial not only for the health and safety of operators but also for maintaining the quality of polished products.

5. Durability and Maintenance Built with high-quality materials, the ODM polishing machine is designed for longevity. Moreover, its maintenance requirements are minimal, allowing for lower operational costs in the long run.

Benefits of Using ODM Stainless Tube Polishing Machine

The implementation of the ODM Stainless Tube Polishing Machine offers numerous benefits to businesses

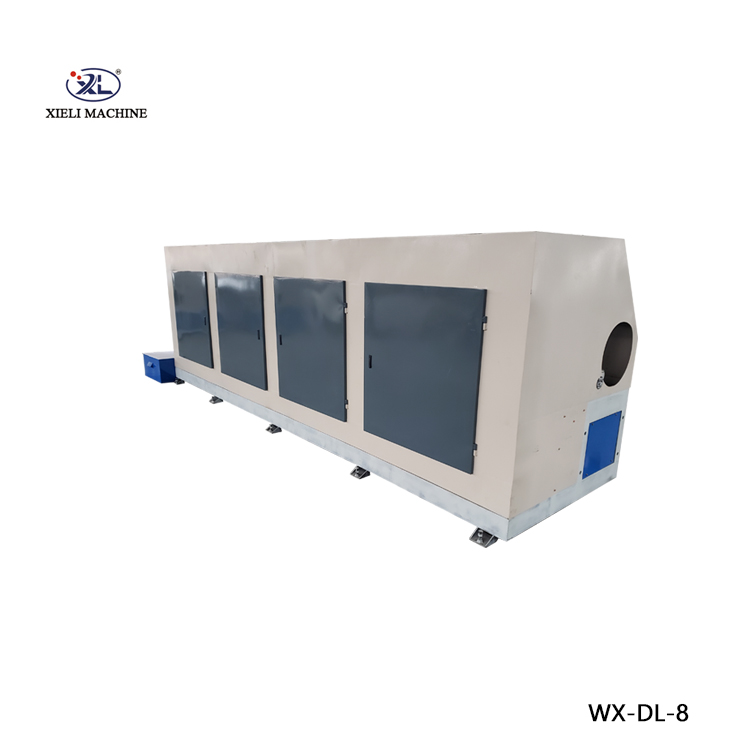

odm stainless tube polishing machine

- Enhanced Quality Polished stainless steel tubes not only look better but also have improved resistance to corrosion and oxidation. This enhances the overall quality of the final product.

- Cost-Effectiveness By reducing the time and labor involved in polishing processes, the ODM machine can lead to significant cost savings. Shorter production times allow companies to meet demand more efficiently.

- Versatility The adaptability of the machine to various tube types and sizes makes it an ideal investment for businesses that work with different projects, from automotive components to architectural fixtures.

- Improved Safety With automated processes and effective waste management, the machine enhances workplace safety, reducing the risk of accidents and ensuring a healthier work environment.

Applications

The ODM Stainless Tube Polishing Machine finds applications across various industries

- Automotive Industry Polished stainless steel tubes are commonly used in vehicle exhaust systems and other components where aesthetics and performance are crucial.

- Architecture and Construction Stainless steel is favored in construction for its durability and visual appeal. The polishing machine provides the necessary finish for architectural accents.

- Food and Beverage Industry Equipment and tubing used in food processing must be polished to meet hygiene standards. The ODM machine is perfect for preparing these components without compromising cleanliness.

Conclusion

The ODM Stainless Tube Polishing Machine represents a significant step forward in the polishing process for stainless steel tubes. Its blend of speed, efficiency, and versatility makes it an invaluable tool across various industries. As businesses continue to seek ways to improve production processes and product quality, investing in advanced machinery like the ODM polishing machine is undoubtedly a strategic move. This machine not only enhances the aesthetic qualities of products but also contributes to operational excellence, making it a game changer in the world of industrial finishing.