The Advantages of Using ODM Square Tube Polishing Machines

In the modern manufacturing landscape, the finishing of products often plays a pivotal role in determining not just the aesthetics but also the functionality of the final items. Among various finishing processes, polishing stands out as an essential step, especially for square tubes that are widely used in industries ranging from construction to automotive. The ODM (Original Design Manufacturer) square tube polishing machine has become a preferred choice for many manufacturers due to its efficiency, precision, and versatility. This article will explore the benefits of using ODM square tube polishing machines and why they are gaining popularity in industrial applications.

One of the primary advantages of ODM square tube polishing machines is their ability to deliver high-quality finishes. The machines are designed to work with different types of materials, including stainless steel, aluminum, and other alloys. The polishing process removes surface imperfections, scratches, and oxidation, resulting in a smooth and shiny surface that enhances the overall appearance of the product. This is especially important in industries where aesthetics matter, such as in consumer products, furniture, and architecture.

The Advantages of Using ODM Square Tube Polishing Machines

Precision is another significant advantage offered by ODM square tube polishing machines. These machines are equipped with advanced technology and computer numerical control (CNC) systems that ensure consistent polishing results. With the ability to set specific parameters for thickness, speed, and pressure, manufacturers can achieve uniform polishing across all products. This level of precision is crucial for industries where tolerance levels are stringent, ensuring that all components fit correctly in assemblies and perform as expected.

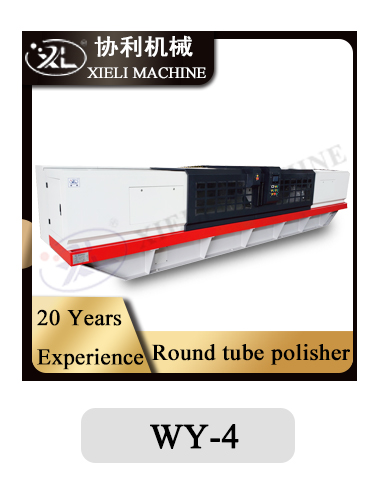

odm square tube polishing machine

Flexibility in operation is a notable characteristic of ODM square tube polishing machines. They can be adjusted to accommodate various tube sizes and shapes, making them suitable for different applications. Whether it’s a small batch of custom-made square tubes or a large production run, these machines can adapt to the task at hand. Furthermore, many models allow for quick changeovers between different polishing processes, enabling manufacturers to switch between various materials and surface finishes without significant downtime.

Additionally, the durability and longevity of ODM square tube polishing machines cannot be overlooked. Designed with robust materials and advanced engineering, these machines can withstand rigorous use in high-volume production environments. Investing in quality machinery not only ensures long-term operational efficiency but also minimizes the costs and disruptions associated with frequent maintenance and repairs.

Sustainability is becoming an increasingly critical concern in manufacturing processes. ODM square tube polishing machines are designed with energy efficiency in mind, requiring less power than traditional systems. Many of them utilize closed-loop systems to recycle polishing compounds, reducing waste and environmental impact. By adopting these machines, manufacturers can contribute to their sustainability goals while enjoying cost savings on materials and energy consumption.

In conclusion, ODM square tube polishing machines offer a multitude of benefits that make them indispensable in various manufacturing settings. With their ability to deliver high-quality finishes, enhance efficiency, ensure precision, and provide operational flexibility, these machines position themselves as a vital investment for manufacturers. Furthermore, their durability and alignment with sustainability principles add to their appeal. As industries continue to evolve and demand for superior products rises, embracing advanced polishing technology like the ODM square tube polishing machine is not just a trend but a necessary step toward maintaining competitiveness in the market.