Understanding ODM Ovality in Centerless Grinding

Centerless grinding is a crucial manufacturing process used to achieve high precision and efficiency when shaping cylindrical parts. One important aspect of this process is ODM (Outer Diameter Measurement) ovality, which refers to the deviation from a perfect circular shape of the outer diameter of the workpiece. Ensuring minimal ovality is vital for maintaining the quality and performance of the final product, especially in applications where precision is critical.

Understanding ODM Ovality in Centerless Grinding

Another factor contributing to ODM ovality is the wear and condition of the grinding wheel. Over time, the grinding wheel can become unevenly worn, impacting its grinding capabilities. This uneven wear can cause fluctuations in material removal rates, leading to variations in the diameter of the workpiece. Regular maintenance and dressing of the grinding wheel are essential to ensure a consistent profile and reduce the risk of ovality.

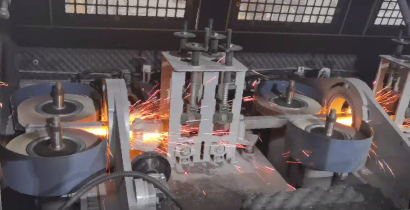

odm ovality in centerless grinder

Furthermore, the feed rate and infeed depth settings can also influence ovality. If the feed rate is too aggressive or the infeed depth is not calibrated correctly, it may lead to excessive pressure on certain areas of the workpiece. This pressure imbalance can cause localized deformation, manifesting as ovality in the finished part.

To minimize ODM ovality, manufacturers often implement rigorous quality control measures throughout the grinding process. This includes precise measurements using advanced metrology equipment to monitor the workpiece's diameter at various points. Additionally, incorporating feedback systems that adjust machine parameters in real-time can help achieve the desired specifications consistently.

In conclusion, understanding and controlling ODM ovality in centerless grinding is essential for producing high-quality components. By focusing on proper alignment, maintaining grinding tools, and optimizing operational parameters, manufacturers can significantly reduce ovality, ensuring that their products meet stringent quality standards and perform reliably in their intended applications.