The ODM Cincinnati Milacron 220-8 Centerless Grinder A Comprehensive Overview

In the realm of metalworking, precision and efficiency are paramount. Among the numerous machines designed to meet these demands, the ODM Cincinnati Milacron 220-8 Centerless Grinder stands out as a remarkable tool. This machine is not just a testament to engineering prowess but also a vital asset for industries requiring high precision in their machining processes. In this article, we will delve into the features, benefits, applications, and maintenance of this iconic grinder.

Introduction to Centerless Grinding

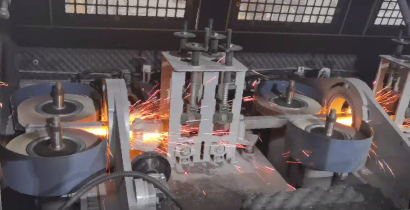

Centerless grinding is a unique form of grinding that operates without the need for a centered fixation of the workpiece. It is distinguished from traditional cylindrical grinding through its setup and operation. In centerless grinding, the workpiece is supported by a rotating grinding wheel and a regulating wheel, allowing for quick and efficient removal of material while maintaining accuracy. This technique is essential for producing cylindrical parts with tight tolerances.

Features of the ODM Cincinnati Milacron 220-8

The ODM Cincinnati Milacron 220-8 Centerless Grinder, with its robust design and advanced technology, caters to a wide range of grinding applications. Below are some notable features of this machine

1. Precision Engineering The grinder is designed to achieve high degrees of accuracy, making it suitable for producing parts with tight tolerances essential in industries such as automotive, aerospace, and manufacturing.

2. Versatility One of the key advantages of the 220-8 model is its ability to handle a variety of workpiece sizes and materials. It can accommodate different grinding operations such as through-feed, in-feed, and end-feed grinding.

3. User-Friendly Controls The intuitive control panel allows for easy adjustments to various parameters, enabling operators to optimize grinding conditions based on specific requirements. This feature significantly reduces setup time and enhances productivity.

4. Durable Construction Built with high-quality materials, the ODM Cincinnati Milacron 220-8 is designed for longevity and reliability. Its robust frame minimizes vibration and enhances stability during operation.

5. Advanced Coolant System The machine is equipped with an efficient coolant system to reduce heat build-up during grinding. This not only extends the lifespan of the grinding wheels but also improves the quality of the finished product by preventing thermal deformation.

Benefits of Using the 220-8 Centerless Grinder

Investing in the ODM Cincinnati Milacron 220-8 Centerless Grinder offers numerous advantages that can significantly enhance manufacturing processes

- Increased Productivity With its ability to perform continuous grinding, the 220-8 improves throughput, allowing manufacturers to meet increasing production demands more efficiently

.odm cincinnati milacron 220-8 centerless grinder

- Cost-Effectiveness The precision and efficiency of this grinder lead to reduced waste and lower operational costs. Manufacturers can achieve more with less material, minimizing scrap rates.

- Quality Assurance The high level of precision provided by the 220-8 results in superior product quality. Consistent machining leads to fewer defects and higher customer satisfaction.

Applications of the ODM Cincinnati Milacron 220-8

The ODM Cincinnati Milacron 220-8 Centerless Grinder finds applications across various industries, including

- Automotive Parts Manufacturing The grinder is ideal for producing components such as shafts, sleeves, and pins, which require precise cylindrical tolerances.

- Aerospace Industry Aerospace applications demand extreme precision, and the 220-8 provides the necessary accuracy for producing critical components like turbine blades and landing gear parts.

- Medical Device Production In the medical field, the grinder is used to manufacture surgical instruments and implants, where precision and reliability are non-negotiable.

Maintenance and Care

To ensure optimal performance and longevity of the ODM Cincinnati Milacron 220-8, regular maintenance is essential

- Routine Inspections Regularly check all components for wear and tear, ensuring that belts, wheels, and bearings are in good condition.

- Cleaning Keep the machine clean by removing debris and coolant residue to prevent contamination and ensure smooth operation.

- Calibration Periodically calibrate the machine to maintain its accuracy. This involves checking the alignment and making necessary adjustments.

Conclusion

The ODM Cincinnati Milacron 220-8 Centerless Grinder is a remarkable machine that exemplifies the intersection of precision engineering and advanced technology. Its versatility and efficiency make it a vital tool in various industries, offering manufacturers a means to achieve high-quality results while optimizing production processes. By investing in such a grinder and adhering to a rigorous maintenance schedule, manufacturers can continue to enhance their operations and deliver exceptional products to the market.