Exploring the Role of Regulating Wheels in ODM Centerless Grinders

In the world of precision machining, centerless grinding stands out as a highly efficient and versatile method to process cylindrical workpieces. One of the central components that contribute to the performance and precision of this process is the regulating wheel. This article delves into the significance of regulating wheels in ODM (Original Design Manufacturer) centerless grinders, exploring their function, design considerations, and implications for precision engineering.

What is a Centerless Grinder?

Centerless grinding is a technique used to grind cylindrical shapes without the use of a spindle. This method allows the workpiece to rotate between a grinding wheel and a regulating wheel, which both play unique roles in the grinding process. Unlike traditional grinding methods that require mounting the workpiece in a chuck or fixture, centerless grinding provides continuous operation and eliminates the need for additional setup time.

The Role of the Regulating Wheel

The regulating wheel is essential in the centerless grinding process. Primarily, it controls the speed at which the workpiece rotates and dictates the feed rate of the grinding operation. Positioned at an angle, the regulating wheel engages with the workpiece to maintain its position and ensure a consistent cutting action. The relationship between the grinding wheel and the regulating wheel is critical for achieving precise diameter control and surface finish.

Design Considerations for Regulating Wheels

1. Material Composition Regulating wheels are typically made from various rubber compounds that offer excellent grip and flexibility. The choice of material affects the friction between the wheel and the workpiece, influencing the surface finish and accuracy of the grind.

2. Surface Texture The surface texture of the regulating wheel plays a significant role in its performance. A rougher surface can enhance grip but may lead to increased wear, while a smoother surface may improve longevity but provide less tactile control.

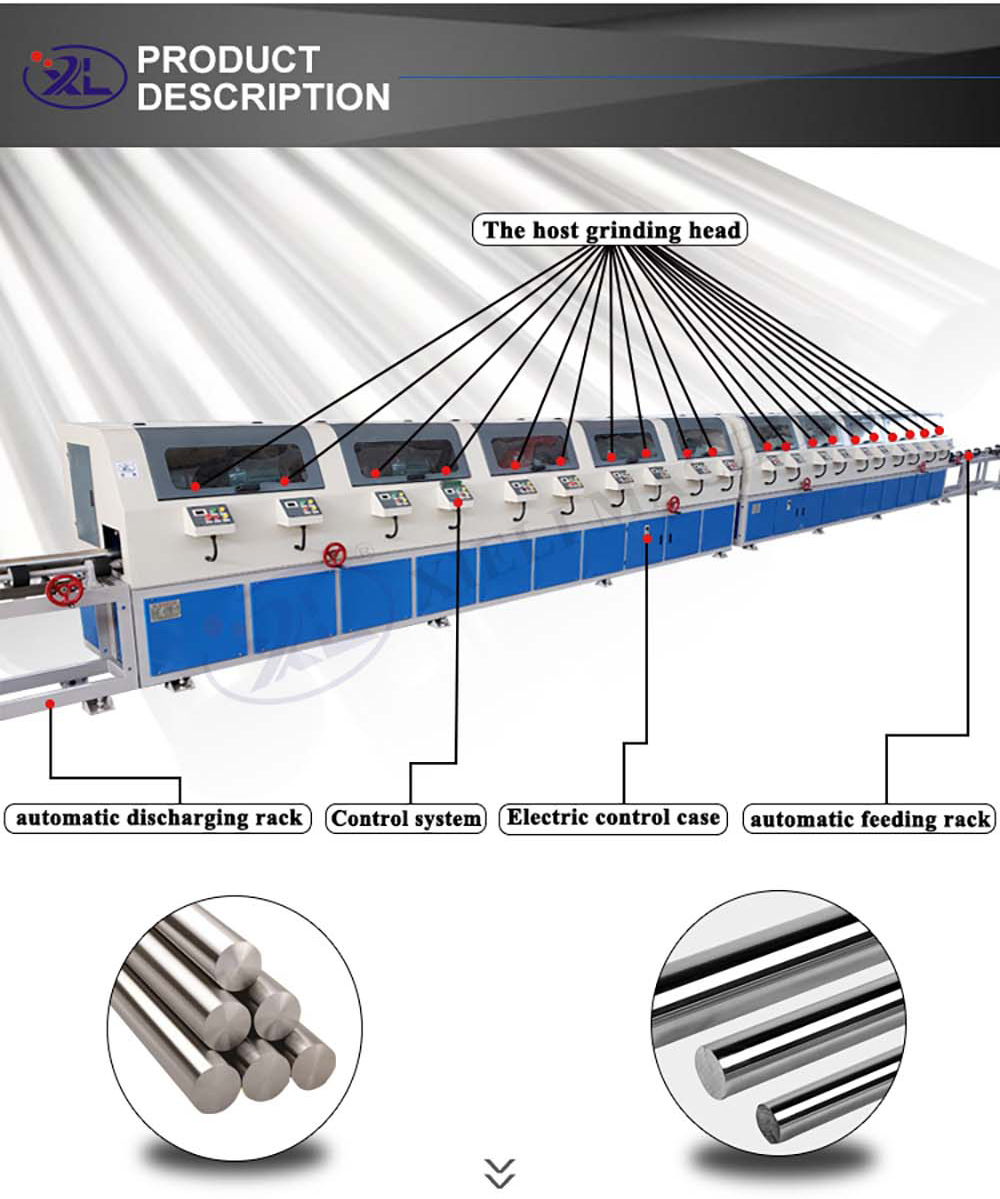

odm centerless grinder regulating wheels

3. Durometer The hardness of the regulating wheel, measured in durometer, is pivotal. A softer durometer allows for better conformity to the workpiece, generating higher friction, while a harder durometer provides durability and longevity.

4. Diameter and Width The diameter and width of the regulating wheel must align with the specifications of the workpiece being processed. An optimal size helps in maintaining stability and reducing vibrations during operation.

5. Angle of Contact The angle at which the regulating wheel contacts the workpiece can dramatically influence the operating characteristics. Adjustments in this angle can optimize the balance between axial and radial forces, enhancing overall performance.

Implications for Precision Engineering

The functionality and design of the regulating wheel in ODM centerless grinders cannot be underestimated. With the increasing demand for high-precision components across various industries—including automotive, aerospace, and medical—the performance of regulating wheels directly influences production efficiency and product quality. Consistent adjustments and innovations in regulating wheel technology can lead to improved grinding processes, reduced cycle times, and enhanced overall productivity.

Conclusion

Regulating wheels are a cornerstone of effective centerless grinding operations in ODM manufacturing. By understanding their design, function, and the intricate relationship between the regulating wheel and the grinding wheel, manufacturers can optimize their processes for better precision and efficiency. As technology advances, the ability to fine-tune these components will continue to play a crucial role in meeting the demanding requirements of modern engineering and manufacturing sectors. Through ongoing research and development, the future of centerless grinding looks promising, with regulating wheels remaining at the forefront of this transformative machining process.

In summary, investing in quality regulating wheels and understanding their mechanics is not just imperative for achieving high productivity but also critical for maintaining the evolving standards of precision machining that define today’s industrial landscape.