The Evolution of ODM Centerless Grinder Manufacturers

In the realm of precision machining, centerless grinders have emerged as a critical tool for manufacturers across various industries. This essential equipment allows for the efficient grinding of parts with high precision and minimal operational downtime. Among the players in this market, ODM (Original Design Manufacturer) centerless grinder manufacturers stand out for their commitment to innovation, quality, and customization.

Understanding Centerless Grinding

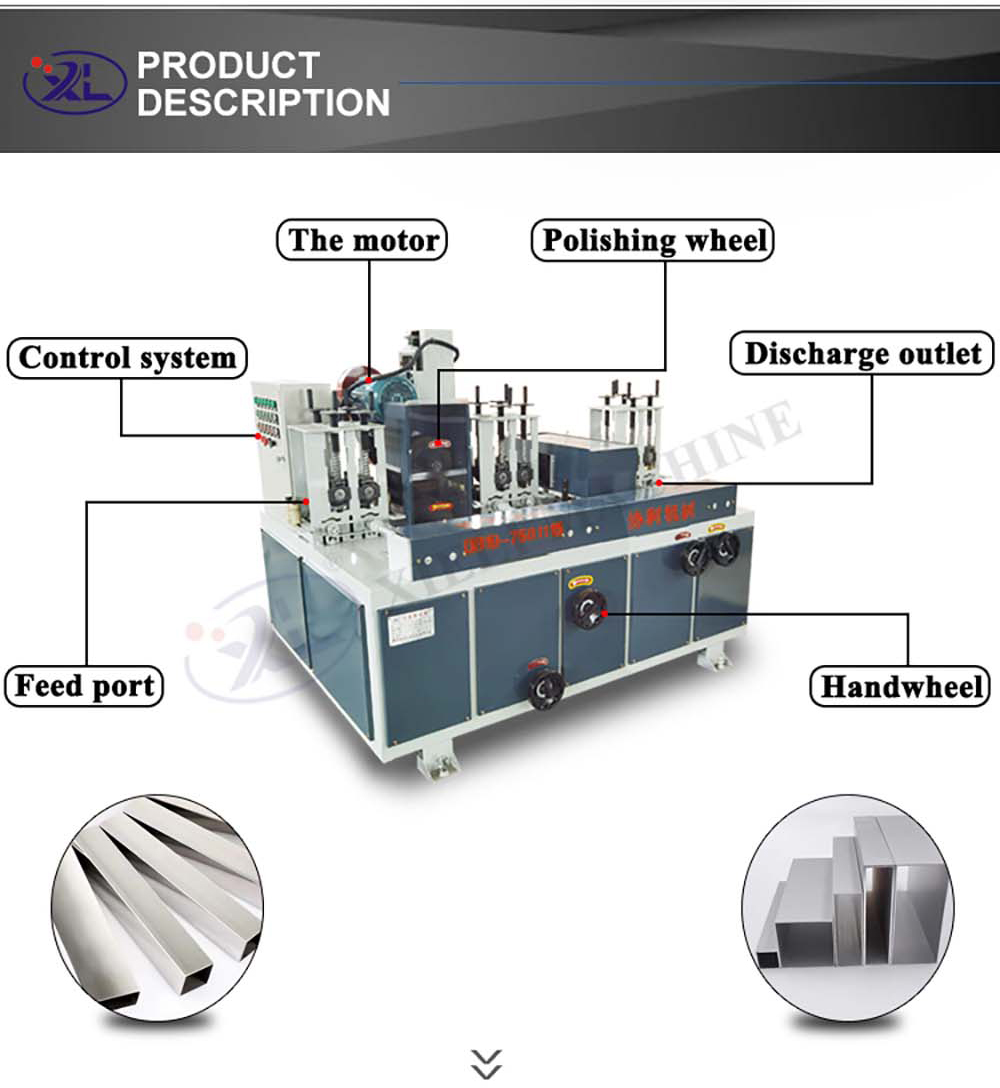

Before delving into the dynamics of ODM manufacturers, it’s vital to appreciate the fundamentals of centerless grinding. Unlike traditional grinding methods, which involve securing the workpiece between centers, centerless grinding utilizes a different approach. The part is positioned between two wheels — a grinding wheel and a regulating wheel — which do not require the same securing method. This process not only facilitates faster production but also allows for grinding multiple parts simultaneously, making it ideal for large-scale manufacturing.

The Role of ODM Centerless Grinder Manufacturers

ODM centerless grinder manufacturers are instrumental in the ongoing evolution of grinding technologies

. These companies specialize in designing and producing machines tailored to the specific needs of their clients. By collaborating closely with customers, ODM manufacturers can incorporate unique specifications and features into their equipment, enhancing efficiency and productivity.One significant advantage of working with ODM manufacturers is the flexibility they offer. Rather than relying on standard, off-the-shelf solutions, companies can receive custom-built machines that cater explicitly to their production requirements. This customization can include modifications in size, grinding techniques, or even the incorporation of advanced automation features.

Innovations in Technology

odm centerless grinder manufacturers

Technological advancements are at the forefront of the manufacturing landscape, and ODM centerless grinder manufacturers are no exception. The integration of computer numerical control (CNC) technology has revolutionized the precision of grinding processes. CNC machines allow for enhanced control over the grinding parameters, leading to better consistency and higher-quality finishes.

Moreover, new materials and components are being explored, enabling manufacturers to reduce wear and tear on their machines. The use of advanced sensors and monitoring systems has led to improvements in machine maintenance, allowing for predictive maintenance schedules that minimize downtime and improve profitability.

The Importance of Quality Assurance

Quality assurance remains paramount in the manufacturing process, particularly for industries where precision is non-negotiable, such as aerospace, automotive, and medical equipment. ODM centerless grinder manufacturers typically implement rigorous testing and inspection protocols to ensure that each machine meets the highest standards. This commitment to quality not only builds trust with customers but also enhances the overall reputation of the manufacturer.

Conclusion

As industries continue to evolve, the demand for efficient and precise machining solutions, such as centerless grinders, is only expected to grow. ODM centerless grinder manufacturers play a pivotal role in meeting these demands by providing customized solutions that enhance productivity and ensure high quality. Through continuous innovation and a focus on quality assurance, these manufacturers are not just contributing to the grinding industry; they are redefining it.

In summary, the landscape of ODM centerless grinder manufacturing is one characterized by collaboration, innovation, and a relentless pursuit of excellence. As businesses seek to stay competitive in a rapidly changing market, partnering with a reputable ODM manufacturer can provide the edge needed to thrive. In an age where precision and efficiency are paramount, the role of these manufacturers will undoubtedly become increasingly significant, shaping the future of machining technology.