Understanding ODM Centerless Grinder Manufacturers A Comprehensive Overview

In the competitive landscape of manufacturing, precision and efficiency play crucial roles in the production of high-quality components. One vital machine that facilitates this precision is the centerless grinder. Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece, and it has become an industry standard for producing cylindrical shapes with tight tolerances. The increasing demand for these machines has led to a proliferation of ODM (Original Design Manufacturer) centerless grinder manufacturers, who specialize in providing tailored solutions to meet specific customer requirements.

What is an ODM?

An ODM is a company that designs and manufactures products based on the specifications provided by another company, which then markets the finished goods under its own brand name. This business model allows companies to bring innovative products to market without investing heavily in research and development. In the context of centerless grinders, ODM manufacturers can offer unique designs and functionalities that cater to the specific needs of various industries, such as automotive, aerospace, and tooling.

The Role of Centerless Grinders

Centerless grinders are essential for processes that require high precision and consistency. Unlike traditional grinders, which rely on a spindle to hold the workpiece, centerless grinders use a system of wheels—one stationary and one rotating—to hold and grind the workpiece in place. This results in faster production rates, reduced setup times, and improved accuracy. Their ability to perform machining without the need for fixtures makes them invaluable for high-volume production environments.

The Advantages of Working with ODM Centerless Grinder Manufacturers

1. Customization and Innovative Designs ODM manufacturers typically offer customizable solutions that align with the specific workflows and manufacturing processes of their clients. This flexibility allows companies to integrate the grinders seamlessly into their production lines, optimizing efficiency.

2. Cost-Effectiveness Partnering with an ODM can significantly reduce costs, as companies don't need to invest resources into product development. Instead, they can focus on marketing and distribution, leveraging the expertise of the ODM in design and manufacturing.

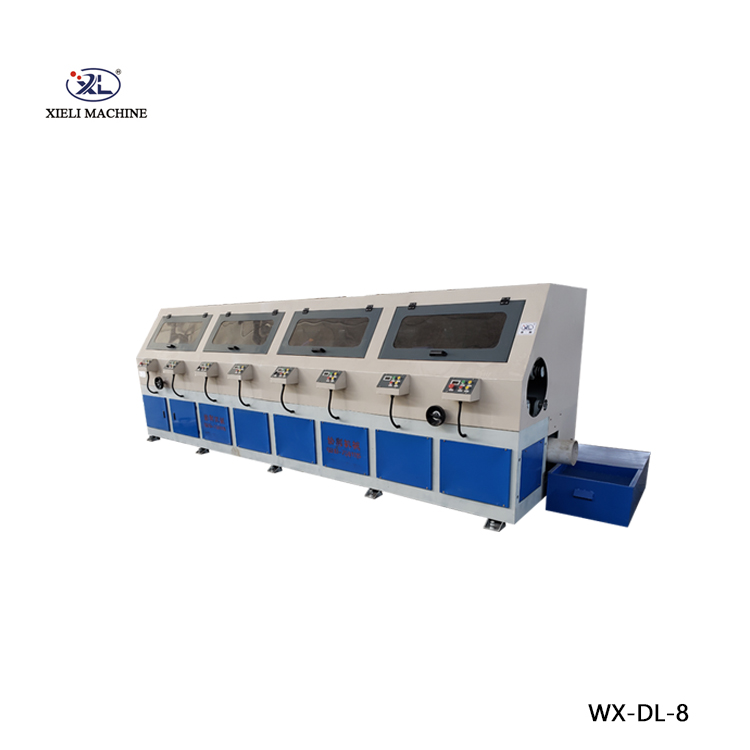

odm centerless grinder manufacturers

3. Quality Control Reputable ODM centerless grinder manufacturers maintain stringent quality control measures throughout the production process. This ensures that every machine meets the highest industry standards and delivers the precision required for critical manufacturing processes.

4. Rapid Prototyping and Production Leading ODM manufacturers utilize advanced technologies and lean manufacturing principles, enabling them to develop prototypes quickly and move to full-scale production with minimal delays. This agility helps businesses meet market demands promptly.

5. Technical Support and After-Sales Service Established ODM manufacturers often provide comprehensive technical support and after-sales services, ensuring that clients receive assistance throughout the lifecycle of their machines. This support is crucial for maintenance, troubleshooting, and optimizing the grinding process.

Choosing the Right ODM Centerless Grinder Manufacturer

When selecting an ODM manufacturer for centerless grinders, several factors should be considered

- Experience and Reputation Look for manufacturers with a proven track record in producing high-quality grinders. Client testimonials and case studies can provide insights into their capabilities. - Design Capabilities Ensure the manufacturer can provide customized designs that suit your specific production needs.

- Technology and Innovation Assess the level of technology used in their manufacturing processes. Advanced technologies can lead to improved machinery performance.

- Post-Sales Support Evaluate the level of customer support offered post-purchase, including training, maintenance, and availability of spare parts.

In conclusion, ODM centerless grinder manufacturers offer valuable solutions to companies seeking to enhance their manufacturing processes through high-precision grinding technology. By understanding the benefits of working with these manufacturers and carefully selecting the right partner, businesses can significantly improve their operational efficiency and product quality. As industry demands continue to evolve, the role of ODMs in providing innovative and customized solutions will remain pivotal in the manufacturing landscape.