ODM Bar Polishing Machine Enhancing Surface Finishing Efficiency

In today's highly competitive manufacturing environment, the need for precision and quality in the production process has never been more critical. Among various production tools and equipment, the ODM (Original Design Manufacturer) bar polishing machine has emerged as an essential asset for industries focused on metalworking and surface finishing. This article explores the significance, features, and benefits of ODM bar polishing machines, highlighting how they can transform a manufacturing operation.

Understanding the ODM Bar Polishing Machine

An ODM bar polishing machine is specifically designed for the polishing of metal bars, tubes, and rods made from different materials like stainless steel, aluminum, and bronze. These machines automate the polishing process, ensuring uniformity in surface finishes, which is crucial for both aesthetic and functional purposes. The versatility of these machines allows them to be used in various sectors, including automotive, aerospace, and construction.

Key Features of ODM Bar Polishing Machines

1. Automated Polishing Process ODM bar polishing machines incorporate advanced automation technology that reduces manual labor. This automation not only increases efficiency but also minimizes the risk of human error, ensuring consistent quality across production runs.

2. Adjustable Settings Different materials and finishes require various polishing techniques. ODM machines come equipped with adjustable speed settings, pressure controls, and customizable polishing tools that can accommodate the specific requirements of the job at hand.

3. High Production Capacity An ODM bar polishing machine can handle multiple pieces simultaneously, significantly speeding up the production process. This capability is particularly beneficial for large manufacturing operations aspiring to meet high demand without compromising quality.

4. Robust Construction Designed for durability, these machines often feature sturdy frames and components made from wear-resistant materials. This robustness not only extends the lifespan of the machine but also ensures it can withstand demanding industrial environments.

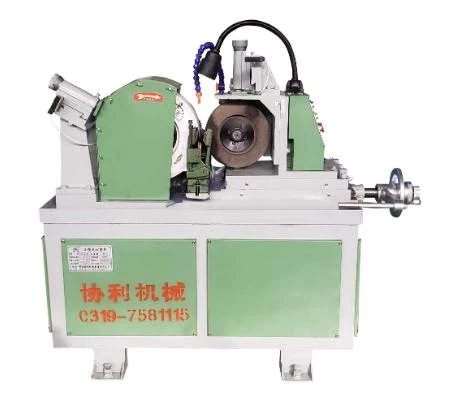

odm bar polishing machine

5. User-Friendly Interface Modern ODM bar polishing machines come with intuitive controls and digital displays that make operation straightforward even for non-experts. Operators can easily configure settings and monitor performance, reducing training time and improving overall productivity.

Benefits of Using ODM Bar Polishing Machines

1. Enhanced Surface Quality One of the primary benefits of using an ODM bar polishing machine is the superior surface finish it delivers. Polished bars not only look better but also exhibit improved characteristics such as corrosion resistance, which is vital in many applications.

2. Cost-Effectiveness While the initial investment in such machinery may be significant, the long-term savings on labor costs and material wastage, coupled with the increased production rates, can lead to a substantial return on investment.

3. Flexibility and Customization Manufacturers can customize ODM bar polishing machines to suit their specific requirements. This adaptability allows for efficient switching between different products and finishes, making it easier to accommodate changing market demands.

4. Environmentally Friendly Solutions Many modern ODM bar polishing machines are designed to minimize waste and energy consumption. Efficient dust collection systems and lower power usage contribute to more sustainable manufacturing practices.

Conclusion

Incorporating an ODM bar polishing machine into manufacturing processes represents a strategic move toward enhancing productivity and product quality. By leveraging advanced technology, these machines not only ensure a high standard of surface finishing but also provide manufacturers with the flexibility and efficiency they need to stay competitive. As industries continue to evolve, the ODM bar polishing machine will undoubtedly play a crucial role in meeting the growing demands for quality, speed, and sustainability in manufacturing. Investing in such machines is not just about keeping pace; it is about setting the standard for excellence in surface finishing.