The Advancements in ODM Round Tube Polishing Machines A Comprehensive Overview

In the realm of manufacturing and metalworking, achieving a polished finish on products is crucial for both aesthetic and functional purposes. Among various types of polishing equipment, the ODM round tube polishing machine has emerged as a sophisticated solution, streamlining the process of surface finishing for round tubes. This article delves into the features, benefits, and applications of these machines, highlighting their significant role in modern manufacturing.

The Advancements in ODM Round Tube Polishing Machines A Comprehensive Overview

One of the standout features of ODM round tube polishing machines is their versatility. They can be adjusted to accommodate different tube diameters and lengths, making them suitable for a wide range of applications. Manufacturers can produce tubes for industries like automotive, aerospace, and construction, where upholding stringent quality standards is essential.

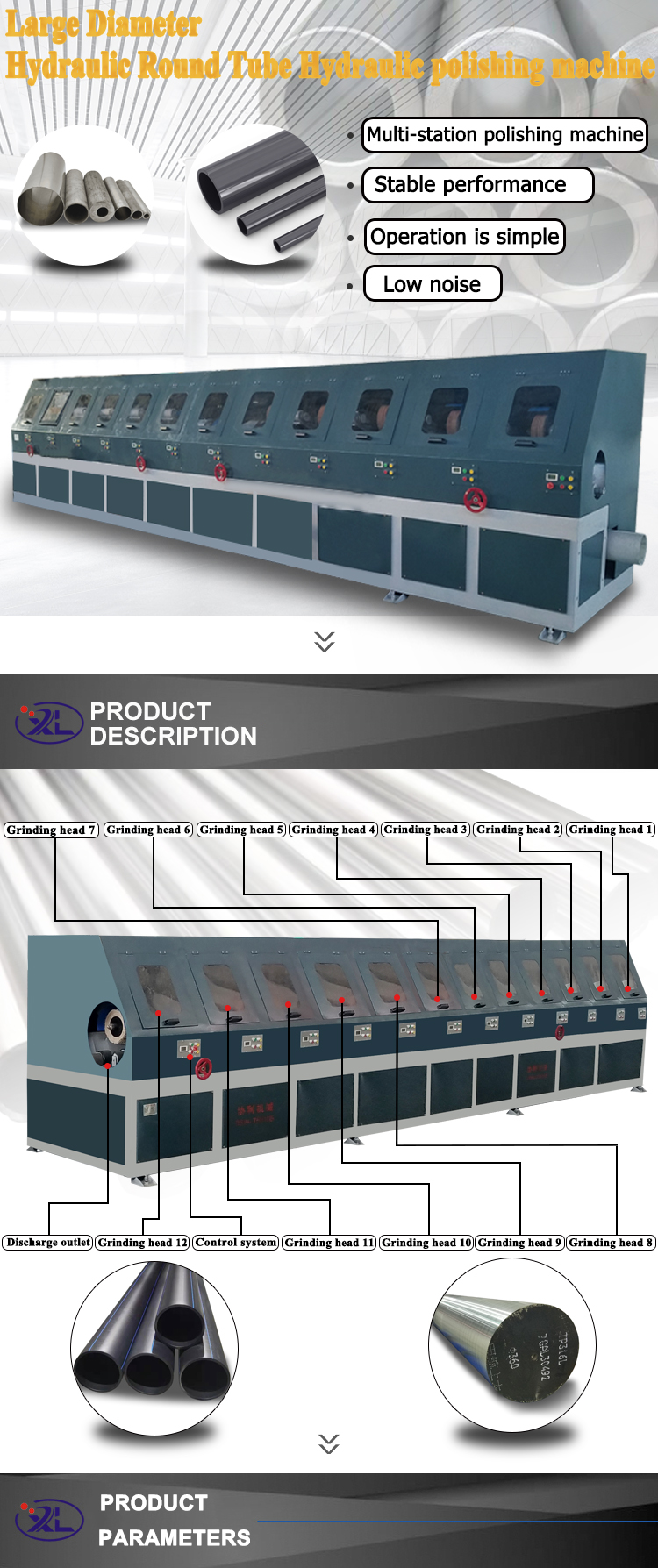

odm round tube polishing machine

The benefits of utilizing an ODM round tube polishing machine extend beyond just aesthetics. A well-polished tube enhances corrosion resistance, improves surface cleanliness, and increases the overall durability of the product. Moreover, by automating the polishing process, manufacturers reduce labor costs and minimize human error, leading to a higher output rate and improved efficiency.

Another significant advantage is the machine's ability to maintain consistency across large batches. In industries where uniformity is critical, such as in the production of medical devices or food processing equipment, having a reliable polishing process can lead to better product quality and safety. The precision offered by these machines allows for the achievement of specific surface finishes that meet regulatory standards.

Furthermore, the integration of advanced technology into ODM round tube polishing machines has led to even greater innovations. Many of these machines now feature digital controls, allowing operators to fine-tune settings with ease. Some models come equipped with monitoring systems that track performance metrics, helping businesses optimize their operations and reduce downtime.

In conclusion, ODM round tube polishing machines represent a vital advancement in metalworking processes. With their ability to produce high-quality, consistent finishes for various applications, they play a crucial role in ensuring that products not only meet aesthetic standards but also possess the functional qualities required for effective use. As industries continue to evolve, the demand for reliable polishing solutions will only increase, positioning these machines as indispensable tools for manufacturers aiming for excellence.