Exploring the ODM Cincinnati Centerless Grinder 325-12 A Precision Tool for Manufacturing Excellence

In the realm of precision manufacturing, the ODM Cincinnati Centerless Grinder 325-12 stands out as a cornerstone of efficiency and accuracy. This machine is designed for grinding cylindrical parts without the necessity for manual centering, which significantly streamlines the manufacturing process. Whether for small-scale production or large industrial applications, the 325-12 model has proven to be an indispensable asset.

Exploring the ODM Cincinnati Centerless Grinder 325-12 A Precision Tool for Manufacturing Excellence

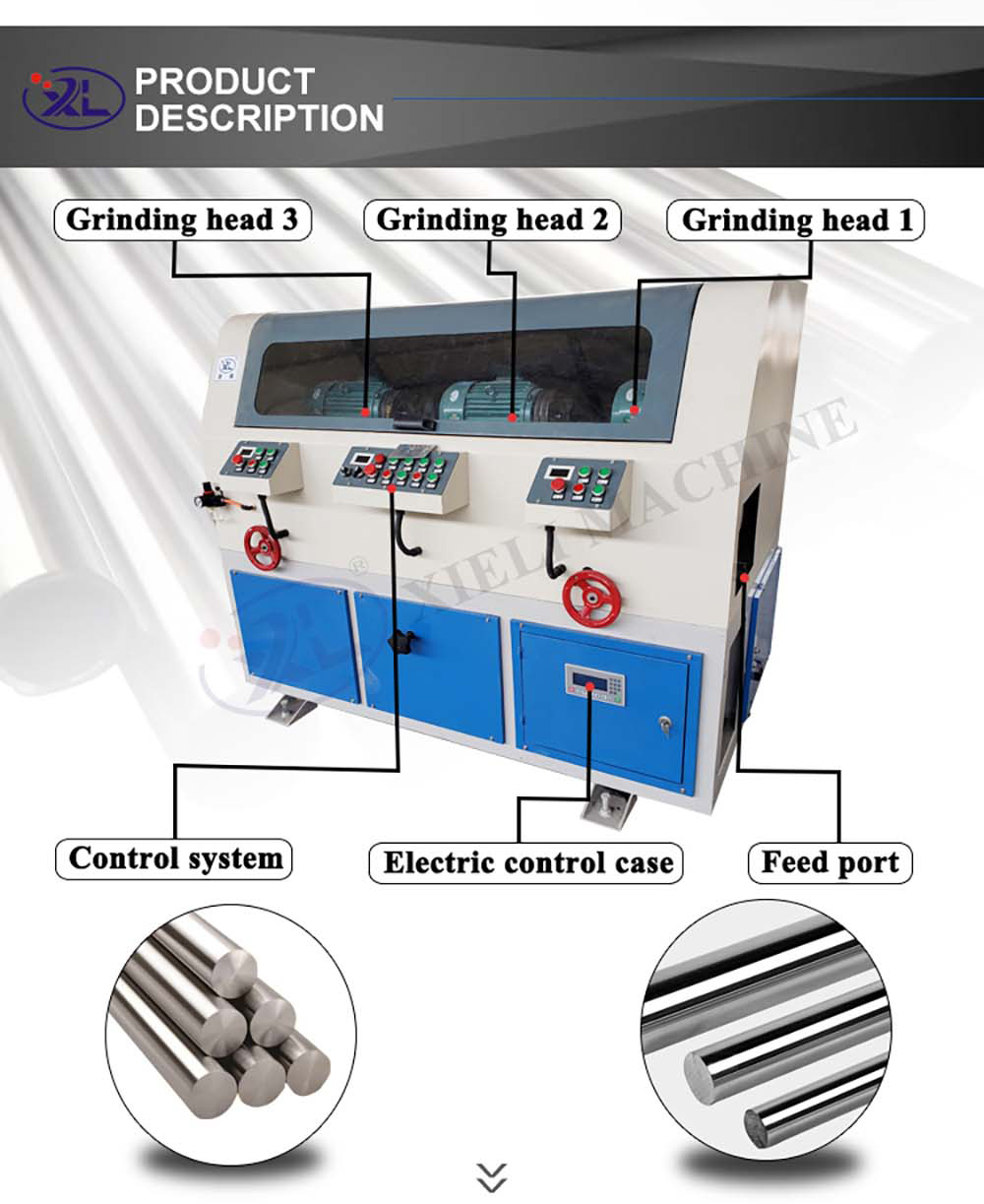

The operation of the 325-12 model is straightforward yet highly effective. Centerless grinding relies on the workpiece being held between two grinding wheels the regulating wheel and the grinding wheel. This setup allows for continuous feed of the workpieces, thereby increasing throughput without sacrificing quality. The adjustable height and angle settings of the machine make it versatile enough to accommodate a range of sizes and shapes, thereby catering to various manufacturing needs.

odm cincinnati centerless grinder 325-12

Furthermore, the ODM Cincinnati Centerless Grinder is equipped with a user-friendly interface that enhances operator efficiency. The controls are designed for ease of use, enabling operators to quickly adjust settings to compensate for different materials and desired finish specifications. This user-centric design minimizes downtime and maximizes productivity, making the 325-12 an excellent return on investment for any manufacturing facility.

Another significant benefit of the 325-12 model is its low maintenance requirement. The high-quality materials used in its construction, combined with its precise machining, reduce wear and tear, allowing for longer intervals between maintenance checks. This not only reduces maintenance costs but also ensures that the machine remains operational and productive for extended periods.

The versatility of the ODM Cincinnati Centerless Grinder also extends to its compatibility with various accessories designed to enhance its functionality. Add-ons such as automatic loading systems and enhanced coolant delivery mechanisms can be integrated, further optimizing production lines and improving efficiency. This adaptability makes the 325-12 suitable for both high-volume production runs and custom machining projects.

In conclusion, the ODM Cincinnati Centerless Grinder 325-12 represents a significant investment in manufacturing technology. Its advanced features—combined with ease of operation, low maintenance requirements, and adaptability—make it an essential tool for companies striving for excellence in precision grinding. As industries continue to evolve and demand higher precision, machines like the 325-12 will play a critical role in meeting those challenges, ensuring that manufacturers can produce high-quality, reliable components that meet stringent standards.