The Advantages of New Centerless Grinding Machine Services

In the realm of precision manufacturing, the importance of accurate and efficient grinding processes cannot be overstated. Among the various grinding techniques available, centerless grinding has gained significant traction due to its ability to produce high-quality finished products with minimal human intervention. The advent of new centerless grinding machines has further revolutionized this process, and with it, the services that accompany these machines have evolved to meet the demands of modern manufacturing.

Centerless grinding is a process that allows for the grinding of cylindrical workpieces without the need for holding them between centers. This method offers several distinct advantages over traditional grinding techniques. Firstly, it facilitates a continuous production line, significantly increasing throughput. This is particularly beneficial for manufacturers handling high volumes of parts, as it reduces cycle times and enhances overall productivity.

New centerless grinding machines are equipped with advanced features that improve precision and consistency. With the integration of computer numerical control (CNC) technology, these machines can produce parts that meet stringent tolerances with minimal operator oversight. The automation of the grinding process not only enhances accuracy but also helps in reducing human error, leading to better overall product quality.

Moreover, the latest centerless grinding machines are designed with energy efficiency in mind. They utilize modern drive systems and innovative cooling technologies to minimize power consumption while maintaining optimal grinding performance. This is crucial in today’s industrial landscape, where sustainability is a top priority for manufacturers aiming to reduce their carbon footprint and operational costs.

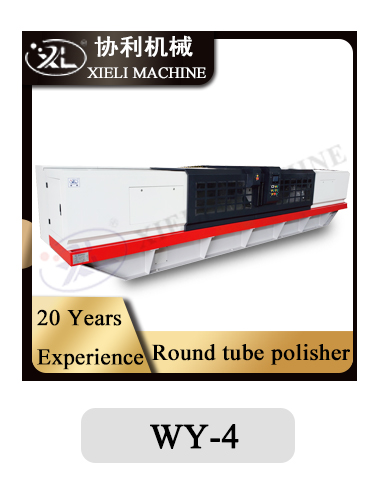

new centerless grinding machine service

Service offerings for new centerless grinding machines have also expanded in response to the technological advancements in the industry. Comprehensive maintenance services are essential to ensure that these machines operate at peak efficiency. Regular servicing helps to prevent breakdowns and prolong the life of the equipment. Service providers often include preventive maintenance checks, which can identify potential issues before they escalate into costly repairs.

In addition to maintenance, training services for operators are critical. With the added complexity of modern machines, having well-trained personnel is essential for maximizing productivity and minimizing downtime. Service providers offer specialized training programs to educate operators about the intricacies of the machines, covering aspects such as setup, operation, and troubleshooting. This knowledge not only empowers employees but also enhances overall operational efficiency.

Another significant aspect of new centerless grinding machine services is the availability of technical support. Manufacturers can benefit from responsive and knowledgeable support teams that can provide assistance quickly when challenges arise. This level of support ensures that any operational disruptions are resolved swiftly, enabling factories to maintain their production schedules.

Finally, customization services are increasingly popular in the industry. Different applications may require specific modifications to grinding machines. Service providers that offer bespoke solutions can help manufacturers tailor their machines to better suit their unique production needs, ensuring optimal performance for specialized grinding tasks.

In conclusion, the emergence of new centerless grinding machine services represents a critical advancement in the manufacturing sector. With increased efficiency, precision, and support, these services not only facilitate improved production processes but also empower manufacturers to stay competitive in a rapidly evolving market. As technology continues to advance, embracing these services will be paramount for businesses looking to maximize their success in precision machining.