The Rise of New Centerless Grinding Machine Exporters

In the competitive world of manufacturing, precision and efficiency are paramount. Among the critical processes that ensure these factors are met is grinding technology, specifically centerless grinding. With industries continually seeking precision-engineered components, the need for advanced grinding solutions has led to the emergence of new centerless grinding machine exporters, transforming how industry players approach production.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is held between centers, centerless grinding uses two rotating wheels a grinding wheel and a regulating wheel. This setup allows for continuous operations, enhancing productivity and consistency in producing cylindrical parts. The primary advantage of centerless grinding is its efficiency in processing materials with complex geometries and tight tolerances.

The Need for Advanced Technology

As industries evolve, the demand for high-performance machinery has escalated. Manufacturers are increasingly focused on minimizing downtime, maximizing output, and achieving tighter tolerances. Traditional grinding machines may no longer suffice in meeting these rigorous requirements. Thus, new centerless grinding machine exporters are stepping up, introducing innovative machines equipped with state-of-the-art technology.

These new machines often feature digital interfaces, advanced sensors, and automation capabilities, which allow for real-time monitoring and adjustments. Such advancements significantly improve precision and efficiency, enabling manufacturers to adapt quickly to changing production demands.

Global Market Growth

The rise of new centerless grinding machine exporters can be attributed to several factors, including globalization and the expanding manufacturing sector in emerging economies. As countries like China, India, and Brazil invest heavily in infrastructure and industry, there is a growing demand for high-precision components, driving the need for advanced grinding solutions.

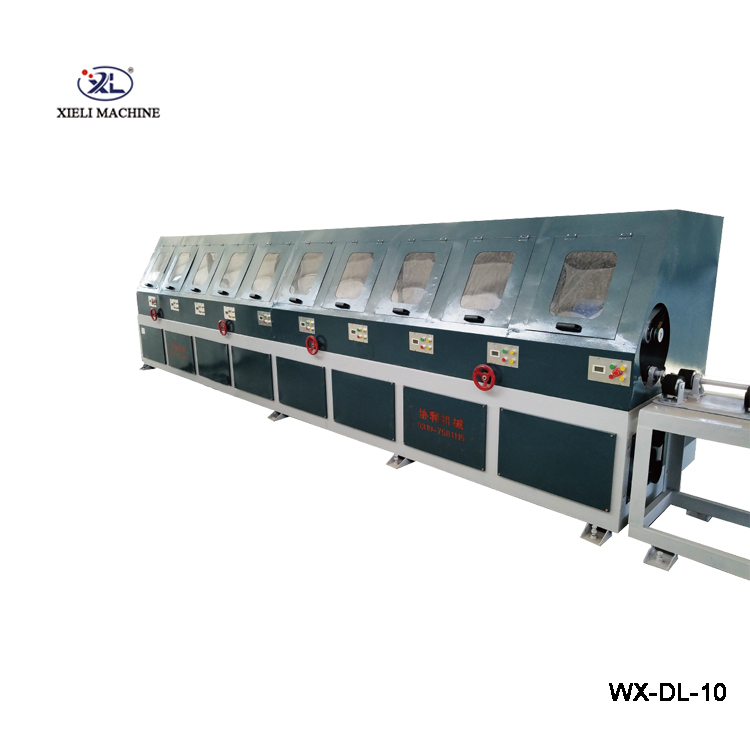

new centerless grinding machine exporter

Moreover, established manufacturers in developed countries are increasingly looking to outsource certain production processes or machinery to maintain competitive advantages

. As a result, exporters of centerless grinding machines have found robust markets across continents, fostering international partnerships and collaborations.Key Players in the Market

The centerless grinding machine market has witnessed the emergence of numerous exporters who specialize in providing high-quality machinery tailored to specific industry needs. Leading exporters are focused not only on supplying machines but also on offering comprehensive support services, including maintenance, training, and technical assistance.

These players leverage their expertise in engineering, technology, and supply chain management to deliver customized solutions to clients. Such a tailored approach ensures that manufacturers can maximize the value they derive from these machines, ultimately leading to increased productivity and profitability.

Future Trends

Looking ahead, the centerless grinding machine market is poised for continued growth. Innovations in artificial intelligence (AI) and machine learning (ML) are likely to play a significant role in the industry. By integrating these technologies into grinding machines, exporters can enhance process optimization, predictive maintenance, and overall efficiency.

Additionally, sustainability is becoming a crucial consideration in manufacturing. New centerless grinding machines will likely focus on reducing energy consumption, minimizing waste, and incorporating eco-friendly practices. Exporters who prioritize sustainable technology will be well-positioned to meet the needs of a growing market that values environmental responsibility.

Conclusion

The emergence of new centerless grinding machine exporters is reshaping the landscape of precision machining. As industries demand higher efficiency and accuracy, these exporters are stepping in to provide advanced solutions tailored to modern manufacturing needs. By embracing innovation and sustainability, they are paving the way for a future where precision grinding continues to play a vital role in the production of high-quality components across various sectors. As the global market expands, these exporters will be essential partners in facilitating the growth and success of manufacturing industries worldwide.