The Rise of Multi-Head Automatic Polishing Machine Suppliers Revolutionizing the Polishing Industry

In today’s rapidly evolving manufacturing landscape, the demand for efficient and high-quality polishing solutions has never been greater. Multi-head automatic polishing machines represent a significant advancement in this field, offering exceptional precision and speed in surface finishing processes. With the rise of global suppliers specializing in these machines, manufacturers across various industries can now access cutting-edge technology that enhances productivity while reducing operational costs.

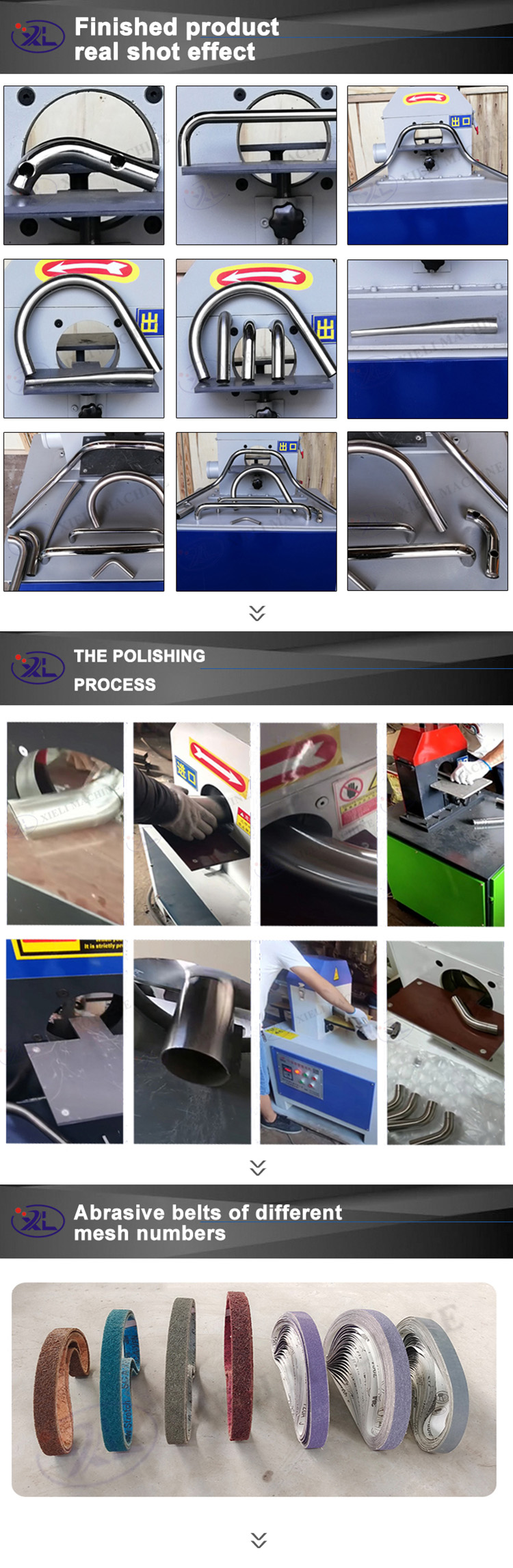

Multi-head automatic polishing machines are equipped with multiple polishing heads that simultaneously work on the workpiece's surface. This design not only improves the polishing process's efficiency but also ensures uniformity in finish, which is crucial for sectors such as automotive, aerospace, electronics, and jewelry manufacturing. The capability to handle multiple surfaces simultaneously allows these machines to significantly reduce cycle times, freeing up valuable labor and resources for businesses.

One of the key trends in the market for multi-head automatic polishing machines is the increasing customization capabilities provided by suppliers. Many manufacturers now offer bespoke solutions, allowing clients to tailor machines to their specific requirements. This customization can range from adjusting the size and configuration of the polishing heads to selecting specific materials and finishes that align with the client's production goals. By working closely with suppliers, companies can achieve enhanced operational efficiency and a competitive edge in their respective markets.

multi-head automatic polishing machine supplier

Moreover, the technological advancements in automation and artificial intelligence play a crucial role in the evolution of these polishing machines. Today's multi-head polishers are often integrated with advanced software that enables real-time monitoring and adjustments. This integration not only enhances the quality of the finished product but also allows for predictive maintenance, minimizing downtime and extending the life of the machinery. Suppliers who invest in R&D and prioritize innovation are better positioned to meet the diverse needs of their customers.

Sustainability is another critical factor that has influenced the rise of multi-head automatic polishing machine suppliers. As industries strive to reduce their environmental footprint, many suppliers are focusing on developing machines that use eco-friendly materials and processes. These machines often consume less energy and generate less waste during the polishing process, aligning with the growing demand for sustainable manufacturing practices. Businesses that prioritize sustainability can not only improve their public image but also benefit from cost savings in the long run.

The global market for multi-head automatic polishing machines is becoming increasingly competitive, with suppliers emerging from various regions, including Asia, Europe, and North America. Each supplier brings unique strengths to the table, whether it be through superior technological innovation, exceptional customer service, or competitive pricing. As companies look to upgrade their polishing capabilities, they have a plethora of choices, making it essential for suppliers to differentiate themselves.

In conclusion, the emergence of multi-head automatic polishing machine suppliers is reshaping the polishing industry, providing manufacturers with access to state-of-the-art technology that maximizes efficiency, quality, and sustainability. As these machines continue to evolve with advancements in automation and customization, industries can expect even greater enhancements in their production processes. The future of polishing is undoubtedly bright, driven by the relentless innovation of suppliers who are dedicated to meeting the changing needs of the market. Businesses should seize the opportunity to partner with these suppliers and elevate their polishing operations to new heights.