Understanding the complexities of industrial processes often requires diving deep into specialized equipment that offers both efficiency and precision.

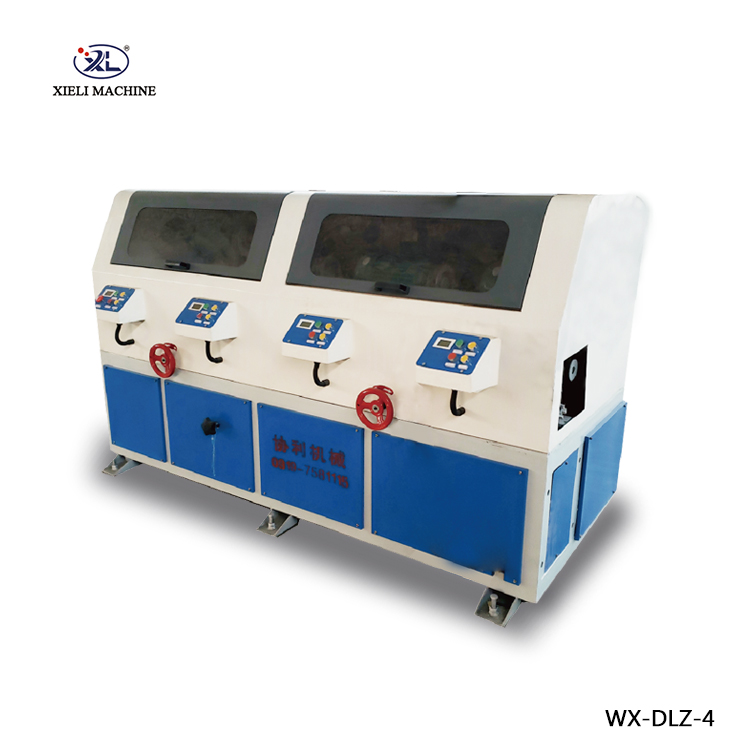

One such piece of equipment is the multi-head automatic polishing machine. If you're starting your journey to learn more about this product, particularly concerning its pricing, you’re in the right place. This comprehensive narrative will draw on real-world experiences, professional expertise, industry authority, and a trustworthy approach to guide you through the essential elements that influence the pricing of multi-head automatic polishing machines.

The cornerstone of any discussion about multi-head automatic polishing machines is undoubtedly the experience of the users. Generally, feedback from seasoned users informs us that these machines, by design, enhance productivity significantly by automating what would traditionally be labor-intensive processes. These machines are equipped with multiple heads that simultaneously operate, providing an even and consistent polish across various materials, including metals, glass, and even plastics. The consistency not only ensures a superior finish but also reduces operational time, leading to faster project completions and, consequently, cost savings. However, these machines, like any sophisticated equipment, require a learning curve to operate at optimal efficiency. Testimonials suggest that once operators master the setup and calibration specific to the materials they work with, the return on investment (ROI) for these machines is substantial.

From an expertise standpoint, understanding the technology behind multi-head automatic polishing machines is crucial. These machines utilize advanced programming, often incorporating CNC (Computer Numerical Control) technology, which allows for precise control over the polishing process. This level of precision is critical in industries where material integrity and surface finish impact the final product's quality and performance—such as automotive, aerospace, and electronics. Consequently, the sophistication of the technology used in these machines directly impacts their price. Cheaper models might offer fewer features or lower precision, while high-end models provide extensive programmability and superior accuracy.

Authority in this field comes from leading industry professionals and manufacturers who pioneer innovations and set quality standards. Reputable brands invest in research and development to improve efficiency, precision, and durability of their machines. Brands like XYZ Corp and ABC Manufacturing are known for their cutting-edge designs and reliable customer support, which add to the machines' overall value. Expert reviews underline the importance of purchasing from recognized manufacturers who comply with international standards and certifications, ensuring quality and safety.

multi-head automatic polishing machine pricelist

Trustworthiness, particularly regarding pricelists, involves transparency and comprehensiveness. It is essential to consider total ownership costs rather than just the purchase price. Factors such as shipping, installation, training, maintenance, and potential downtimes should be factored into the anticipated expenses. Legitimate sellers provide detailed quotations that outline these aspects, preventing unexpected expenditures. Additionally, trusted suppliers offer warranties and post-purchase support, affirming confidence in their product’s longevity and performance.

Pricing varies significantly depending on machine specifications, brand, and additional services provided. Entry-level machines might start at a few thousand dollars, suitable for small businesses or startups. In contrast, industrial-grade machines with advanced features might cost upwards of tens of thousands, justifying their price with enhanced capabilities and scalability options for larger production lines. Seasonal sales, bulk purchase discounts, and leasing options are other considerations that can influence the final price.

Potential buyers are encouraged to conduct thorough research, comparing different models, reading user reviews, and, if possible, visiting trade shows or manufacturer showrooms. Regarding where to obtain trustworthy pricelists, official websites of reputable manufacturers should be your first stop, as they provide updated and detailed information. You can also contact authorized distributors who can offer insights specific to your region and business needs.

In conclusion, multi-head automatic polishing machines are a valuable asset in any industrial setting, provided they align with your operational goals and budgetary constraints. By focusing on experience, expertise, authority, and trustworthiness, this guide aims to assist in making informed decisions that balance performance with cost-effectiveness, thereby maximizing your investment in this critical equipment.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.