The Rise of Multi-Head Automatic Polishing Machines Revolutionizing the Manufacturing Industry

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. Among the innovations that have emerged to meet these demands is the multi-head automatic polishing machine. This advanced machinery is transforming various sectors by enhancing production capabilities while ensuring a high-quality finish on diverse surfaces.

A multi-head automatic polishing machine employs multiple polishing heads that operate simultaneously. This design allows for a significant increase in throughput compared to traditional single-head machines. As the demand for precision and speed in manufacturing continues to rise, these machines offer an effective solution, particularly in industries such as automotive, aerospace, and heavy machinery manufacturing.

One of the key advantages of using multi-head polishing machines is their ability to achieve uniformity and consistency in the polishing process. With multiple heads working in tandem, manufacturers can achieve a flawless finish across large batches of products, reducing the likelihood of defects or variations. This quality assurance is crucial in industries where even minor imperfections can lead to product failure or safety concerns.

multi-head automatic polishing machine company

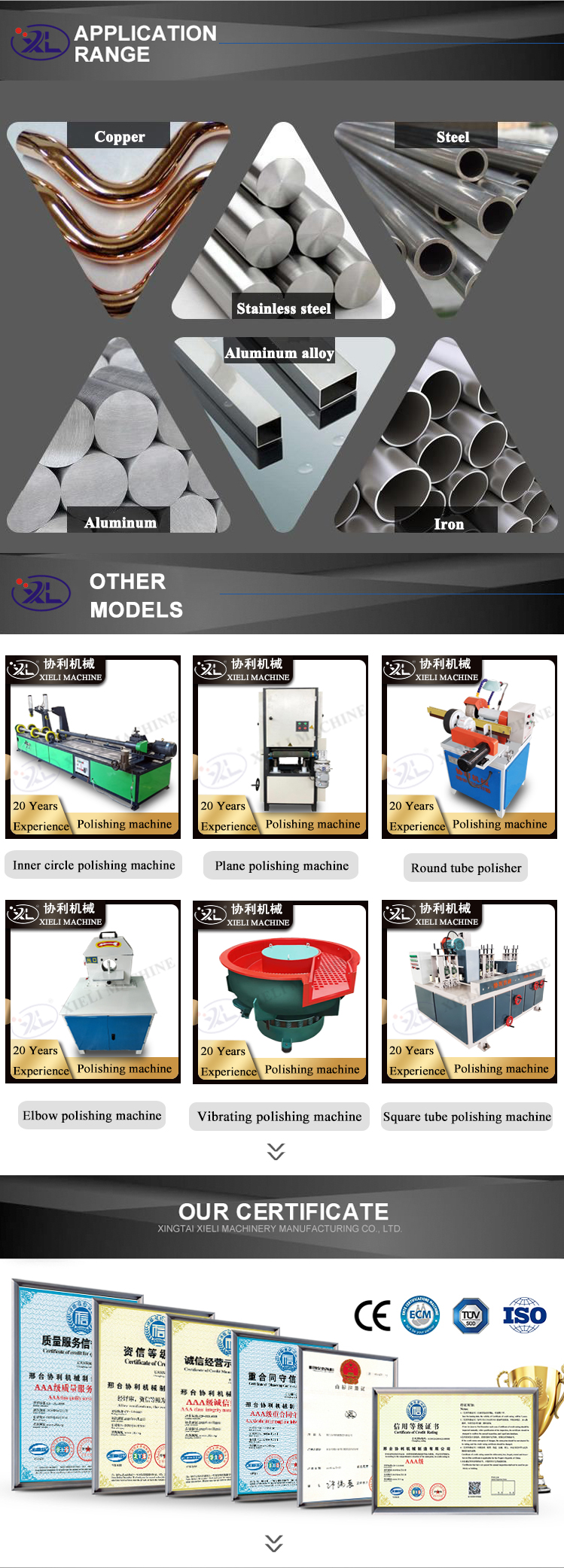

Moreover, these machines can be customized to accommodate various materials, including metals, plastics, and composites. This versatility makes them an invaluable asset for companies looking to streamline their operations across multiple product lines. By investing in multi-head polishing technology, manufacturers can reduce labor costs, minimize downtime, and ultimately increase their profit margins.

In addition to enhancing productivity and ensuring quality, multi-head automatic polishing machines also contribute to sustainability efforts. By optimizing the polishing process, these machines often require less energy and use less abrasive material, making them a more environmentally friendly option. Companies that adopt such technology demonstrate their commitment to responsible manufacturing practices, appealing to increasingly eco-conscious consumers.

Furthermore, the integration of advanced technologies such as automation and artificial intelligence has elevated the capabilities of these machines. Features like real-time monitoring and adjustment capabilities ensure that each polishing head operates at peak efficiency, adapting to the specific requirements of the job. This adaptability not only improves the quality of the final product but also minimizes waste and resource consumption.

In conclusion, the emergence of multi-head automatic polishing machines represents a significant advancement in the manufacturing industry. By offering enhanced efficiency, consistent quality, and greater versatility, these machines are helping companies to meet the rising demands of modern production. As the industry continues to evolve, those who invest in such innovative technology will likely lead the way, driving progress and setting new standards in manufacturing excellence. With the ongoing focus on automation and sustainability, the future looks bright for multi-head automatic polishing machines and the industries that embrace them.