Monza Centerless Grinder Supplier Quality and Precision in Grinding Technology

In the evolving world of manufacturing, precision engineering plays a crucial role in the production of high-quality components. A significant part of this process involves grinding technology, where centerless grinders are indispensable. Among the key players in this domain, Monza stands out as a leading supplier of centerless grinders, renowned for their innovative designs and exceptional performance.

Understanding Centerless Grinding

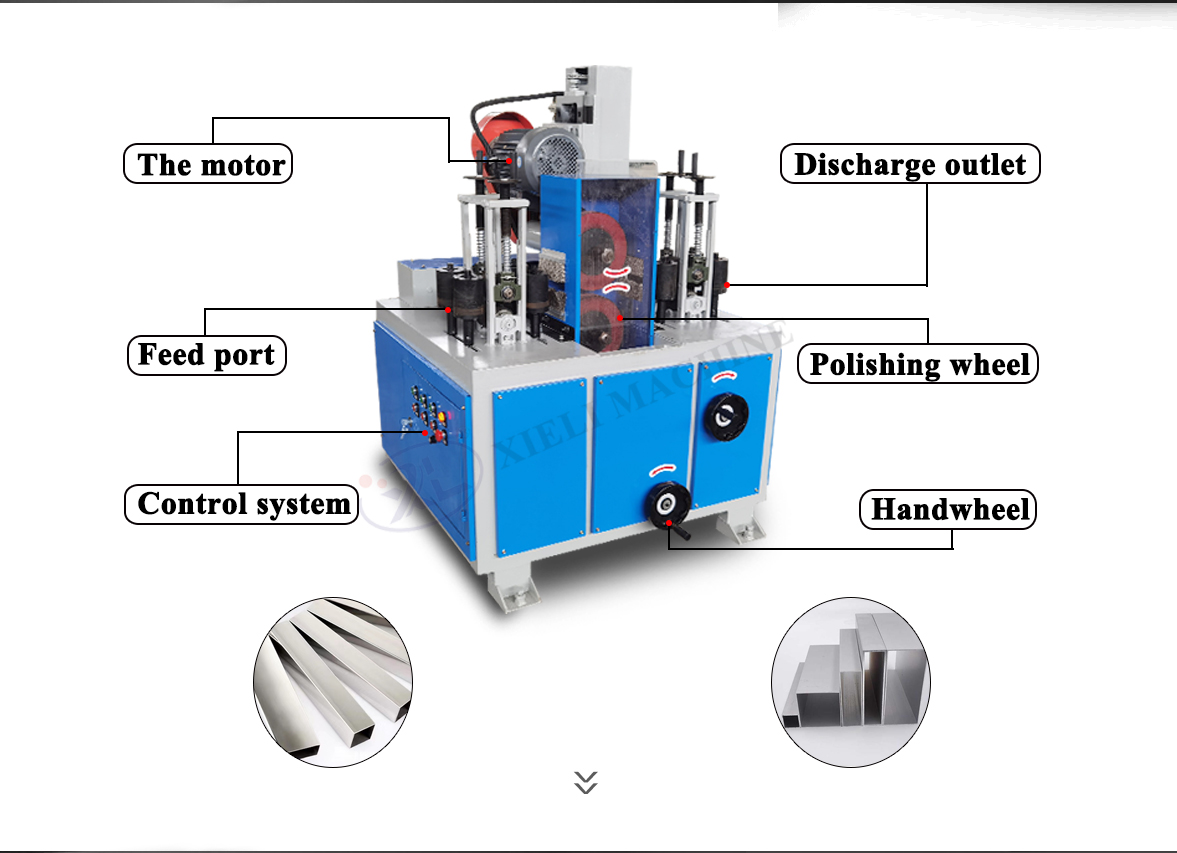

Centerless grinding is a manufacturing process that involves the grinding of cylindrical parts without the need for a center hole. This method provides various advantages, including increased efficiency, versatility, and the ability to produce extremely precise dimensions. The typical centerless grinding setup includes three main components the grinding wheel, regulating wheel, and the workpiece support. The workpiece is fed through the machine and positioned between these two wheels, allowing for continuous grinding without the necessity of manual positioning.

Why Choose Monza Centerless Grinders?

Monza has established itself as a reputable supplier of centerless grinders, offering a comprehensive range of machines that cater to various industrial needs. Here are some reasons why Monza's grinders are preferred by manufacturers worldwide

1. Innovative Technology Monza continuously invests in research and development, ensuring that their machines incorporate the latest advancements in grinding technology. This commitment to innovation helps their clients stay competitive in a rapidly changing market.

2. Precision and Accuracy One of the primary advantages of using Monza centerless grinders is the unparalleled precision they offer. These machines are designed to meet stringent tolerances, making them ideal for industries such as automotive, aerospace, and medical device manufacturing, where every micron counts.

monza centerless grinder supplier

3. Durability and Reliability Monza grinders are built to last, with high-quality materials and craftsmanship ensuring reliability. This durability translates into reduced maintenance costs and minimal downtime, a crucial benefit for manufacturers operating under tight production schedules.

4. Custom Solutions Depending on the specific needs of clients, Monza provides tailored solutions that can include modifications to existing machine models or entirely new designs. This flexibility allows for adaptability in various production environments.

5. Comprehensive Support Monza believes in building long-term relationships with its clients, offering extensive technical support, training, and maintenance services. This customer-centric approach not only enhances operational efficiency but also fosters loyalty and trust in Monza's products.

Applications of Monza Centerless Grinders

The versatility of Monza centerless grinders makes them suitable for various applications across different industries. Whether it’s grinding shafts, bars, or tubes, Monza machines can handle a wide range of materials, including steel, aluminum, and other alloys. Common applications include

- Automotive Parts Production of engine components, valves, and drive shafts where high accuracy is paramount. - Aerospace Components Manufacturing parts that require stringent quality controls and precise dimensions. - Medical Devices Fabrication of components that meet the industry’s high standards for safety and performance.

Conclusion

In today's competitive manufacturing landscape, the choice of grinding technology can significantly impact productivity and product quality. Monza centerless grinders, with their reputation for innovation, precision, and reliability, represent a superior choice for manufacturers seeking to enhance their grinding operations. By opting for Monza machines, companies not only invest in state-of-the-art technology but also gain a partner committed to their long-term success. As industries continue to evolve, Monza remains at the forefront, ready to meet the challenges of tomorrow with advanced grinding solutions that redefine excellence.