Monza 300 Centerless Grinder Factory A Commitment to Precision and Quality

In the world of precision engineering, the Monza 300 Centerless Grinder stands as a beacon of innovation and reliability. As part of Monza's dedication to producing cutting-edge grinding solutions, the Monza 300 has become a vital tool in various manufacturing sectors. The factory where the Monza 300 is produced embodies the company's commitment to excellence, efficiency, and advanced technology.

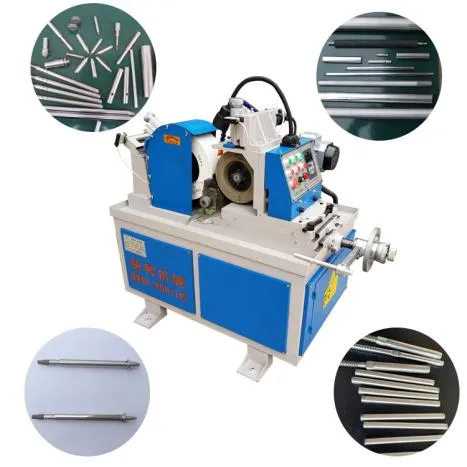

The Monza 300 Centerless Grinder is designed with the needs of modern manufacturing in mind. It enables the efficient grinding of a variety of materials through a process that eliminates the need for centering the workpiece. This is particularly advantageous in high-volume production settings, where speed and precision are critical. With its robust design and advanced features, the Monza 300 significantly enhances productivity while maintaining high-quality standards.

Monza 300 Centerless Grinder Factory A Commitment to Precision and Quality

Monza's factory utilizes state-of-the-art technology and automated processes to streamline production. Advanced computer numerical control (CNC) systems are employed to enhance precision during the manufacturing process. This automation not only improves efficiency but also reduces the likelihood of human error, ensuring that each Monza 300 Centerless Grinder meets stringent quality assurance standards.

monza 300 centerless grinder factory

In addition to technological innovations, the factory prides itself on its skilled workforce. Employees at Monza undergo extensive training to master the intricacies of machine assembly and quality control. Their expertise is complemented by a strong emphasis on teamwork and continuous improvement, driving the factory toward achieving its production goals while maintaining high levels of quality.

Sustainability is another cornerstone of Monza’s manufacturing philosophy. The Monza 300 Centerless Grinder is built with energy-efficient components and materials that reduce the environmental footprint of the manufacturing process. The factory implements sustainable practices such as recycling waste materials and optimizing energy consumption, aligning its operations with global sustainability goals.

The significance of the Monza 300 Centerless Grinder extends beyond its technical capabilities. It represents the fusion of tradition and innovation in the manufacturing sector. The legacy of precision engineering that Monza has built over the years is reflected in every machine produced in this factory. Clients from various industries—including automotive, aerospace, and medical—trust the Monza brand for its commitment to quality and performance.

In conclusion, the Monza 300 Centerless Grinder Factory exemplifies what modern manufacturing can achieve through a combination of advanced engineering, skilled labor, and a dedication to sustainability. As industries continue to evolve, the Monza 300 remains a pivotal tool, enabling manufacturers to meet the demands of precision and efficiency. Monza's relentless pursuit of excellence ensures that its products will remain at the forefront of the grinding technology landscape, shaping the future of precision engineering for years to come.