Exploring the Export Landscape of Mikrosa Centerless Grinding Machines

In the realm of precision manufacturing, centerless grinding machines play a vital role in achieving high accuracy and efficiency in the production of various mechanical components. Among the key players in this field is Mikrosa, a brand known for its innovative approach and superior engineering in centerless grinding technology. This article delves into the significance of Mikrosa centerless grinding machines, their export dynamics, and the global market trends influencing this sector.

Understanding Centerless Grinding

Centerless grinding is a machining process that allows for the precise grinding of cylindrical parts without the need for a fixed spindle, thereby enhancing productivity. This technique is widely used in industries such as automotive, aerospace, and medical devices, where tight tolerances and surface finishes are paramount. Mikrosa has established itself as a leader in this field, recognized for its advanced technology and commitment to quality.

Mikrosa’s Market Position

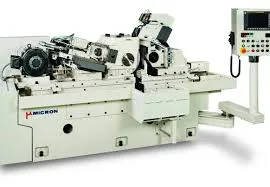

Mikrosa is a subsidiary of the German company, Schaudt Mikrosa GmbH, which specializes in the development and manufacture of centerless grinding machines. With decades of experience, Mikrosa has built a solid reputation in the industry, providing innovative solutions that cater to the diverse needs of various sectors. Their machines are known for their robustness, versatility, and precision, making them highly sought after in the global market.

Export Trends and Challenges

The export of Mikrosa centerless grinding machines has seen a consistent upward trend over the years, driven by the increasing demand for high-quality machined components worldwide. Regions such as North America, Europe, and Asia-Pacific are significant markets for these machines, with countries like the United States, Germany, and China being the largest importers.

mikrosa centerless grinding machine exporters

However, the export landscape is not without its challenges. Trade regulations, tariffs, and fluctuating currency exchange rates can impact pricing and demand. Moreover, the ongoing global supply chain disruptions, particularly in the aftermath of the COVID-19 pandemic, have posed significant hurdles for manufacturers and exporters alike. Mikrosa has adapted to these challenges by enhancing its supply chain resilience and exploring new markets to maintain its competitive edge.

The Role of Technology in Export Success

Technological advancements have played a crucial role in boosting the export potential of Mikrosa centerless grinding machines. With the integration of Industry 4.0 principles, including automation, data analytics, and interconnected systems, Mikrosa machines are increasingly capable of meeting the demands of modern manufacturing. This trend not only enhances production efficiencies but also appeals to international buyers looking for state-of-the-art equipment.

Moreover, the emphasis on sustainability and eco-friendly practices has become increasingly important in global trade. Mikrosa’s commitment to developing energy-efficient machines aligns with the growing demand for sustainable manufacturing solutions, further enhancing its attractiveness in the export market.

Future Outlook

Looking ahead, the future of Mikrosa centerless grinding machine exports appears promising. As industries continue to evolve and the demand for precision engineering intensifies, the role of advanced machining solutions will only grow. Additionally, emerging markets in regions like Southeast Asia and South America present new opportunities for expansion, especially as these regions enhance their manufacturing capabilities.

In conclusion, Mikrosa centerless grinding machines stand as a benchmark in the precision machining industry, driving significant export activity. By leveraging technological advancements and adapting to market challenges, Mikrosa is well-positioned to capitalize on future growth opportunities in the global market. As the demand for precision and efficiency in manufacturing processes continues to rise, Mikrosa's contribution to the centerless grinding segment will remain paramount in shaping the future of the industry.