Micron Centerless Grinding Machine Manufacturer Precision Engineering for Modern Manufacturing

In the realm of precision engineering, the importance of centerless grinding machines cannot be overstated. These marvels of modern manufacturing are pivotal in creating components with tight tolerances and exceptional surface finishes. Among the many manufacturers in this industry, Micron stands out as a leading provider of centerless grinding solutions. This article delves into Micron's contributions to centerless grinding technology and its significance in modern manufacturing.

The Role of Centerless Grinding

Centerless grinding is a process that allows for efficient and precise shaping of round components without the need for a centered fixture. Instead, workpieces are secured between two wheels the grinding wheel and the regulating wheel, which controls the feed rate and speed of the workpiece. This method is particularly beneficial for producing parts in high volumes with consistent quality, making it an ideal choice for industries ranging from automotive to aerospace.

Micron's Expertise in Centerless Grinding

Micron has carved a niche for itself in the manufacturing landscape by specializing in high-precision centerless grinding machines. With years of experience and a relentless focus on innovation, Micron's machines are engineered to produce components that meet the most stringent quality requirements. The company emphasizes research and development, constantly seeking ways to enhance efficiency, reduce production costs, and improve the overall grinding process.

Innovative Technology

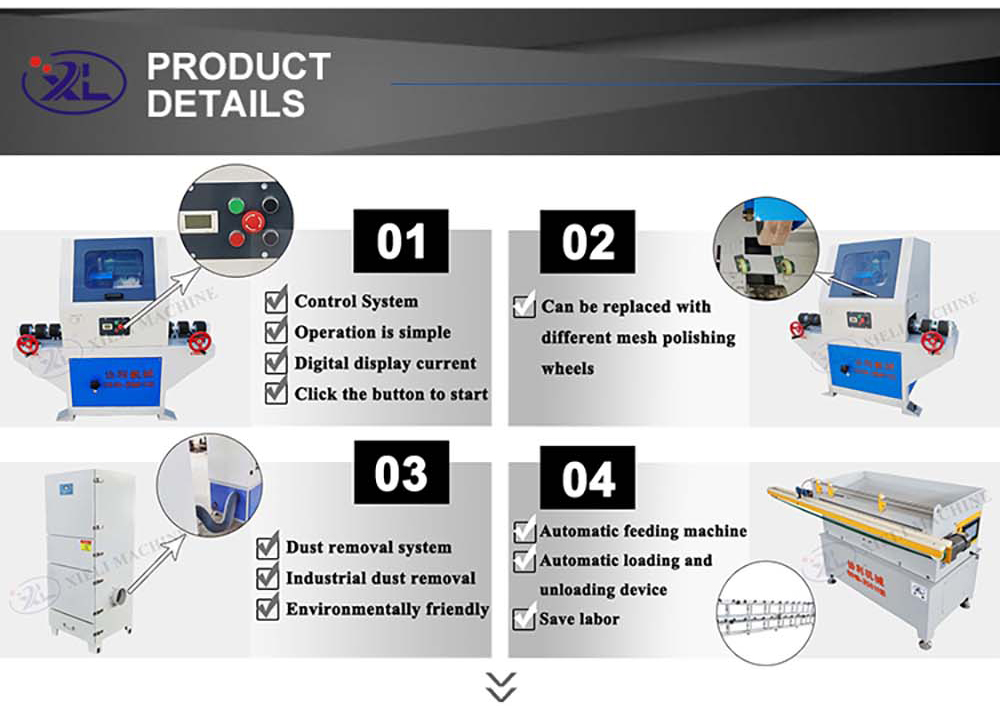

One of the standout features of Micron's centerless grinding machines is their use of cutting-edge technology. By integrating advanced software and automation systems, Micron is able to offer machines that not only provide remarkable precision but also enhance the efficiency of the manufacturing process. Features such as CNC (Computer Numerical Control) capabilities allow for automation in settings and adjustments, ensuring that even the most complex geometries can be achieved with ease.

micron centerless grinding machine manufacturer

Additionally, Micron machines are designed with user-friendly interfaces, making it easier for operators to manage the grinding process. These innovations have made Micron a preferred choice for companies looking to modernize their production lines with state-of-the-art equipment.

Customization and Flexibility

Every manufacturing requirement is unique, and Micron understands this necessity for customization. The company offers a wide range of models that cater to different applications, allowing clients to select machines that best fit their specific needs. Whether it involves grinding materials for the automotive sector or crafting precision parts for the medical industry, Micron's flexibility in machine design enables it to serve a diverse clientele.

Dedication to Quality

Quality assurance is at the heart of Micron’s operations. Each machine produced undergoes rigorous testing and quality checks to ensure unparalleled performance and reliability. Micron is committed to maintaining high standards, adhering to international quality certifications, and investing in the latest technologies to stay ahead in a competitive market.

Conclusion

As industries continue to evolve with the demands for more complex and precise components, the importance of advanced centerless grinding machines will only grow. Micron, with its dedication to innovation, quality, and customer satisfaction, is well-positioned to lead the charge in this sector. By investing in Micron centerless grinding machines, manufacturers can enhance their production capabilities, achieve greater precision, and ultimately drive their businesses to new heights. In a world where precision is paramount, Micron stands as a beacon of excellence in the manufacturing domain, offering solutions that are truly transformative.