In the intricate world of manufacturing, precision often dictates success. As industries evolve, the demand for seamless and efficient operations grows, with many firms seeking the pinnacle of tool-making technology.

Enter the arena of micron centerless grinders—a vital element of modern production lines. These marvels of engineering are not merely tools; they are the heartbeat of precision manufacturing, breathing life into a wide array of industrial applications. For those invested in the pursuit of exactitude, understanding the essence and advantages of the micron centerless grinder is paramount.

At the outset, it's crucial to comprehend the inherent design and functionality that separates micron centerless grinders from conventional grinding methods. Traditional grinding techniques often grapple with the cumbersome task of aligning parts, but centerless grinders eliminate this challenge. By utilizing a centerless system, workpieces are supported between the grinding wheel and a regulating wheel, negating the need for a spindle. This innovative design translates into reduced setup times and a streamlining of the manufacturing process, yielding higher throughput and significant cost reductions.

Micron-level precision is the hallmark of these grinders, making them indispensable in industries where even the slightest deviation in diameter can have catastrophic consequences. Automotive, aerospace, and medical device sectors are just a few industries benefitting from the zero-margin-for-error precision offered by micron centerless grinders. Imagine the minute components of a pacemaker—crafted to be exactly right, or an aerospace part where tolerances are unyieldingly tight. In these scenarios, centerless grinders shine, ensuring every component meets stringent industry standards.

Expertise in utilizing these machines goes beyond basic operational knowledge; it requires a deep appreciation of the interplay between technological capabilities and material science. Skilled operators understand how different materials—from hardened steel to complex alloys—interact with the grinding media. Such expertise ensures the longevity of the grinding wheels and better surface finish quality, ultimately extending the lifespan of the workpieces themselves. This nuanced understanding underscores the importance of seasoned professionals in ensuring optimal machine performance and the delivery of superior end products.

Moreover, the expertise extends into machine maintenance—a critical factor influencing operational continuity. Regularly scheduled maintenance protocols ensure the machinery operates at peak performance, preventing costly downtime. The emphasis on routine checks is grounded in experience; seasoned operators recognize that even a minor misalignment or wear in the components can lead to significant inefficiencies or even complete operational halts.

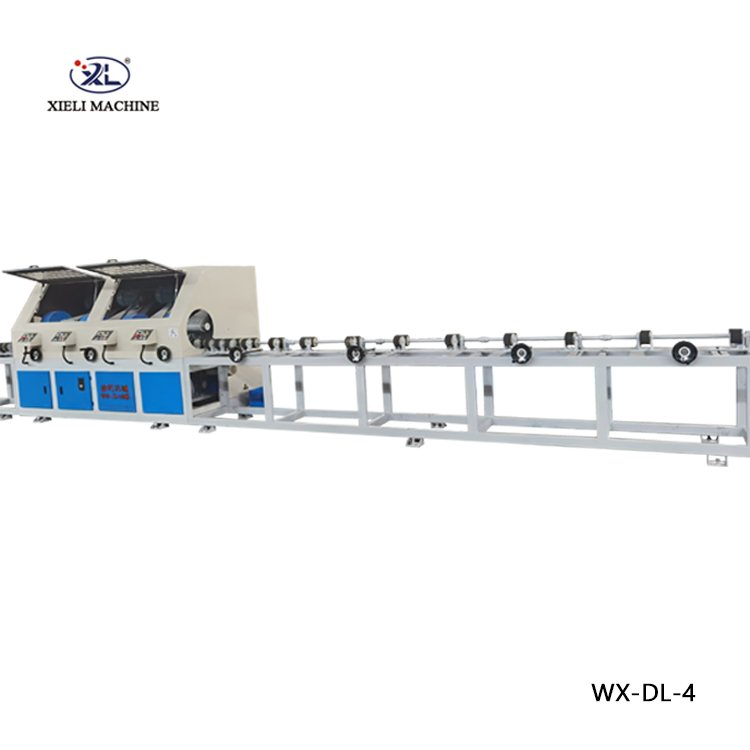

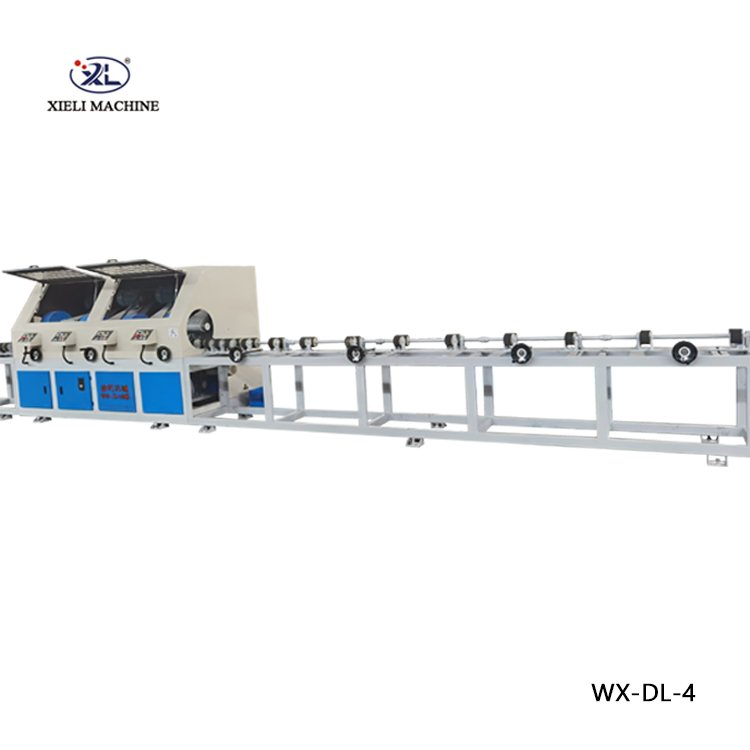

micron centerless grinder factory

In a market teeming with manufacturers, the authority of a reputable micron centerless grinder factory is established through demonstrated reliability and consistent quality output. Factories with a storied legacy not only provide exceptional machinery but also contribute an invaluable repository of knowledge and experience. They become pillars of trustworthiness, underpinning their clients’ manufacturing operations with high-quality equipment and unmatched service support.

Trust in manufacturing tools is not just about having the right equipment; it’s about ongoing partnerships. Factories producing these grinders often collaborate closely with their clients to understand specific needs and tailor solutions that meet unique production requirements. This client-centric approach ensures that the machinery not only fits seamlessly into existing operations but also elevates overall production efficiency.

Furthermore, these relationships are strengthened by common goals innovation and sustainability. Leading factories are now at the forefront of incorporating eco-friendly practices into their operations, focusing on reducing waste and energy consumption. This eco-conscious commitment adds another layer of trust and reliability, offering clients peace of mind that their tools of choice are contributing to a broader positive environmental impact.

In conclusion, the role of micron centerless grinders in precision manufacturing cannot be overstated. For those seeking unparalleled precision, industry expertise, and unwavering reliability, these machines represent an indispensable addition to the production process. Beyond their mechanical prowess, they embody a legacy of innovation, quality, and trust—qualities that are crucial in an ever-evolving industrial landscape.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.