The Micron Centerless Grinder A Key Player in Precision Manufacturing

In the realm of precision manufacturing, few pieces of equipment are as crucial as the centerless grinder. Among the various manufacturers producing high-quality centerless grinding machines, Micron stands out due to its commitment to precision, innovation, and customer satisfaction. Micron centerless grinders are widely recognized for their exceptional performance, durability, and versatility, serving a broad spectrum of industries from automotive to aerospace and beyond.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process that enhances the precision of a workpiece by eliminating the need for a central axis. Unlike traditional grinding techniques that rely on a chuck or mandrel to hold the workpiece in place, centerless grinders utilize two rotating wheels, one of which acts as a grinding wheel while the other serves as a regulating wheel. This unique setup allows for continuous material removal, leading to highly efficient and accurate grinding.

The effectiveness of centerless grinding is evident in its ability to produce parts with tight tolerance levels and smooth finishes, making it ideal for components used in critical applications. Centerless grinders can handle a variety of materials, including metals, plastics, and ceramics, making them versatile machines for any manufacturing facility.

Features of Micron Centerless Grinders

Micron centerless grinders are engineered with advanced technology and precision engineering to ensure optimal performance. One defining feature is the use of highly rigid structures that minimize vibration and increase stability during operation. This rigidity allows for maximum precision, which is essential for industries that demand exacting tolerances.

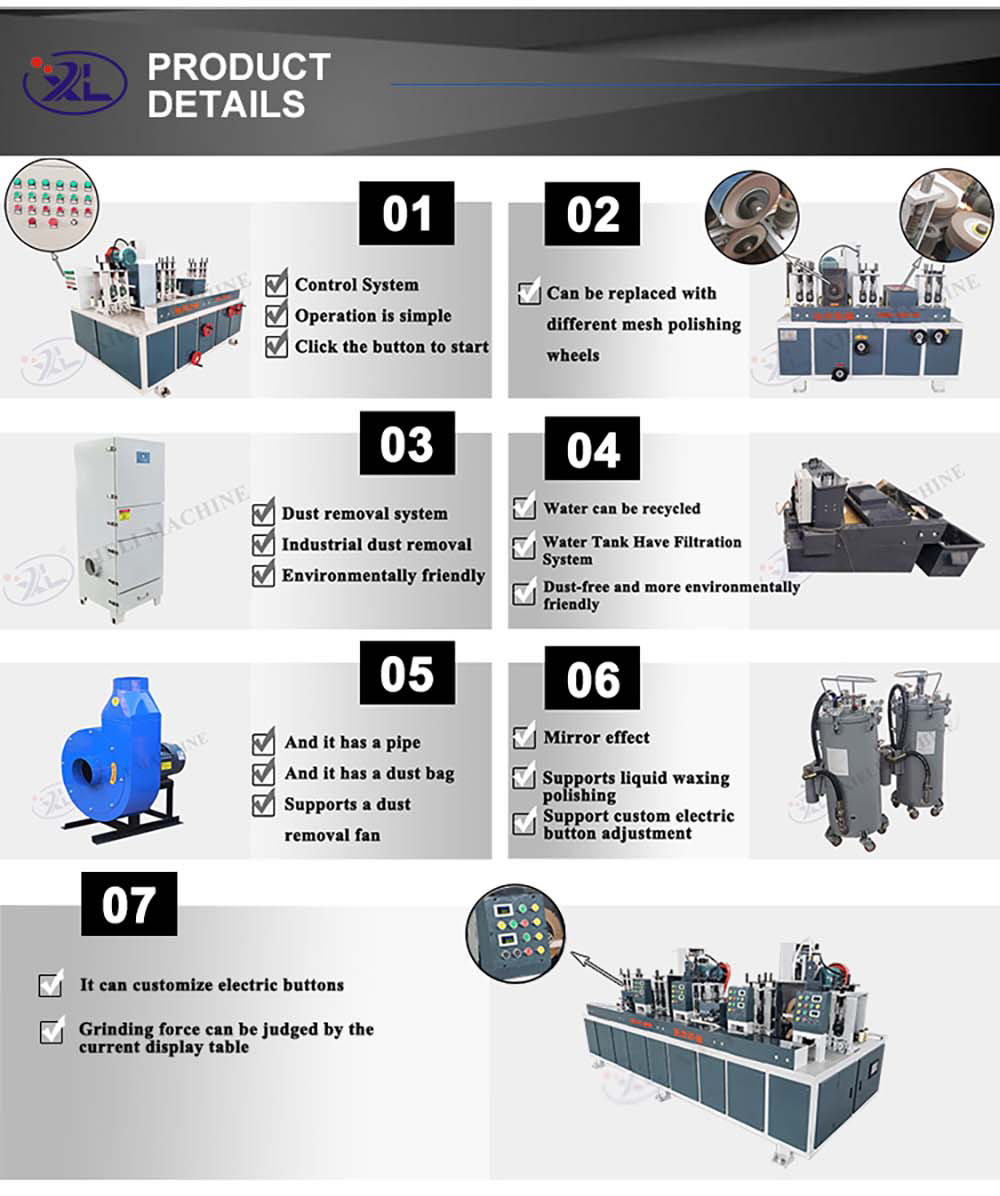

- Advanced Control Systems Micron grinders often include sophisticated control systems, including CNC (Computer Numerical Control) interfaces that allow for precise adjustments and programming. This feature enables manufacturers to produce complex geometries and configurations effortlessly.

- Versatile Wheel Systems Micron’s centerless grinders employ an interchangeable wheel system, which aids in adapting to various grinding needs

. Whether it’s for rough grinding or finishing operations, the flexibility of wheel types and sizes cater to diverse manufacturing processes.micron centerless grinder factories

- Heat Management Effective heat management is critical in grinding, as excessive heat can lead to thermal expansion and affect the integrity of the workpiece. Micron grinders are designed with advanced cooling systems that help maintain optimal temperatures, ensuring consistent results over extended periods.

The Manufacturing Process at Micron Factories

Micron centers its manufacturing process around quality and efficiency. Each machine is meticulously crafted using precision machining techniques, with strict adherence to international quality standards. This commitment to excellence is reflected in their rigorous testing protocols, where every machine undergoes extensive evaluations before reaching the customer. Quality assurance teams at Micron ensure that each grinder performs optimally, meeting or exceeding the customer's specifications.

Sustainability is also a vital component of Micron’s operational philosophy. The company endeavors to minimize waste and reduce its carbon footprint by adopting eco-friendly practices throughout its manufacturing processes. By using renewable resources and optimizing energy consumption, Micron showcases its dedication to sustainable manufacturing.

Customer Support and Legacy

Micron’s commitment to customer support sets it apart from its competitors. The company offers comprehensive training programs, maintenance services, and a robust customer service team to assist buyers in maximizing the performance of their centerless grinders.

Furthermore, the legacy of Micron is built on a foundation of continuous innovation. The brand invests heavily in research and development to stay ahead of industry trends and technological advancements. This proactive approach allows Micron to introduce cutting-edge features and solutions that cater to the evolving needs of manufacturers worldwide.

Conclusion

In summary, Micron centerless grinders represent the pinnacle of precision manufacturing equipment. With their innovative features, commitment to quality, and exceptional customer support, Micron has established itself as a leader in the industry. As manufacturing continues to evolve, Micron remains poised to meet the challenges ahead, empowering manufacturers across various sectors to achieve unparalleled levels of precision and efficiency in their operations.