Understanding Micron Centerless Grinders and Their Global Export Market

Centerless grinding is a machining process that has become essential in the manufacturing of precision components for various industries, from automotive to aerospace. Among the notable players in this domain are micron centerless grinders, which are specialized machines designed for high-precision applications. This article explores the significance of micron centerless grinders, their features, and their impact on the global export market.

What is a Micron Centerless Grinder?

A micron centerless grinder is a type of grinding machine used for producing high-precision parts without the need for a fixture or workpiece holder. Unlike traditional grinding methods, where the workpiece is held stationary, centerless grinders allow for continuous feeding of the workpiece, enabling faster production rates and greater efficiency. This technology is critical in achieving tight tolerances and superior finishes on metal components.

Micron centerless grinders are particularly known for their ability to grind small to medium-sized workpieces with a high degree of accuracy. They typically come equipped with advanced features such as programmable controls, programmable feeds and speeds, and real-time monitoring capabilities. These machines are engineered to provide outstanding performance, durability, and precision.

Advantages of Micron Centerless Grinders

1. High Precision Micron centerless grinders can achieve tolerances in the micro range, making them ideal for industries that require components to meet stringent specifications.

2. Efficiency The centerless grinding process allows for a continuous flow of parts, which significantly improves production output and reduces cycle times compared to traditional grinding methods.

3. Versatility These machines can grind a variety of materials, including metals, plastics, and composites, making them suitable for diverse applications across different industries.

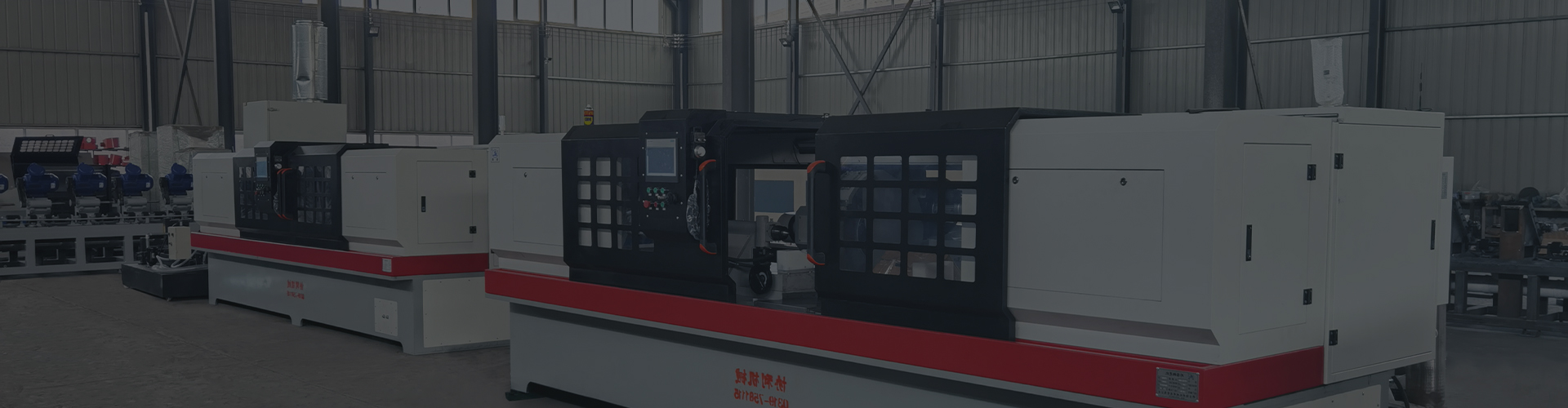

micron centerless grinder exporters

5. Cost-effectiveness While initial investment costs may be higher, the efficiency and reduced labor costs associated with micron centerless grinders often result in lower overall production costs.

The Global Export Market for Micron Centerless Grinders

The market for micron centerless grinders has witnessed significant growth over the past few years, driven by increasing demand from various sectors. Industries such as automotive, aerospace, electronics, and medical equipment are constantly seeking high-precision components, thus fueling the demand for advanced grinding technologies.

Countries such as the United States, Germany, Japan, and China are recognized globally as major exporters of micron centerless grinders. These nations are home to renowned manufacturing firms that specialize in precision machining equipment. The export market for these machines has expanded due to several factors

1. Technological Advancements Continuous innovation and improvement in grinder design and functionalities have made micron centerless grinders more attractive to international purchasers.

2. Rising Demand for Customization As manufacturers look for customized solutions to optimize their production processes, the demand for specialized grinding machines has surged.

3. Globalization of Supply Chains With the globalization of manufacturing, companies are increasingly sourcing precision equipment from international suppliers, leading to a more integrated global market.

4. Growing Emerging Markets Rapid industrialization in developing countries has created new opportunities for the export of high-precision equipment, including micron centerless grinders.

Conclusion

In summary, micron centerless grinders represent a key technology in the precision machining industry, offering unmatched advantages in terms of accuracy and efficiency. As global demand for high-precision components continues to rise, the export market for these advanced grinding machines is poised for further growth. Companies looking to stay competitive will need to invest in the latest grinding technologies, ensuring they can meet the demands of their customers and efficiently navigate the complexities of global trade. The ongoing advancements in machining techniques and the increasing focus on quality manufacturing are likely to solidify the role of micron centerless grinders as an indispensable tool for industries worldwide.