Exploring Micron Centerless Grinder Factories Precision and Innovation in Manufacturing

In the ever-evolving landscape of modern manufacturing, precision engineering plays a pivotal role in meeting the increasingly stringent demands of various industries

. Micron centerless grinder factories are at the forefront of this innovation, specializing in the production of high-performance grinding machinery that facilitates the efficient and accurate processing of various materials.Centerless grinding is a technique that allows for the precise shaping and finishing of products without the need for a spindle or fixture to hold the workpiece. This method is particularly beneficial for manufacturing parts with a high degree of roundness and surface finish. Micron centerless grinders are renowned for their ability to attain tight tolerances and maintain consistency over high-volume production runs, making them indispensable in industries such as automotive, aerospace, medical, and consumer goods.

One of the key elements that set Micron centerless grinder factories apart is their commitment to innovation. These facilities employ cutting-edge technology and engineering practices to enhance the performance of their grinders. For example, many factories utilize advanced CNC (Computer Numerical Control) systems that allow for precise control of various grinding parameters, leading to improved accuracy and efficiency. Moreover, the integration of automation solutions enables these factories to streamline their operations, reducing manual labor and minimizing the risk of errors.

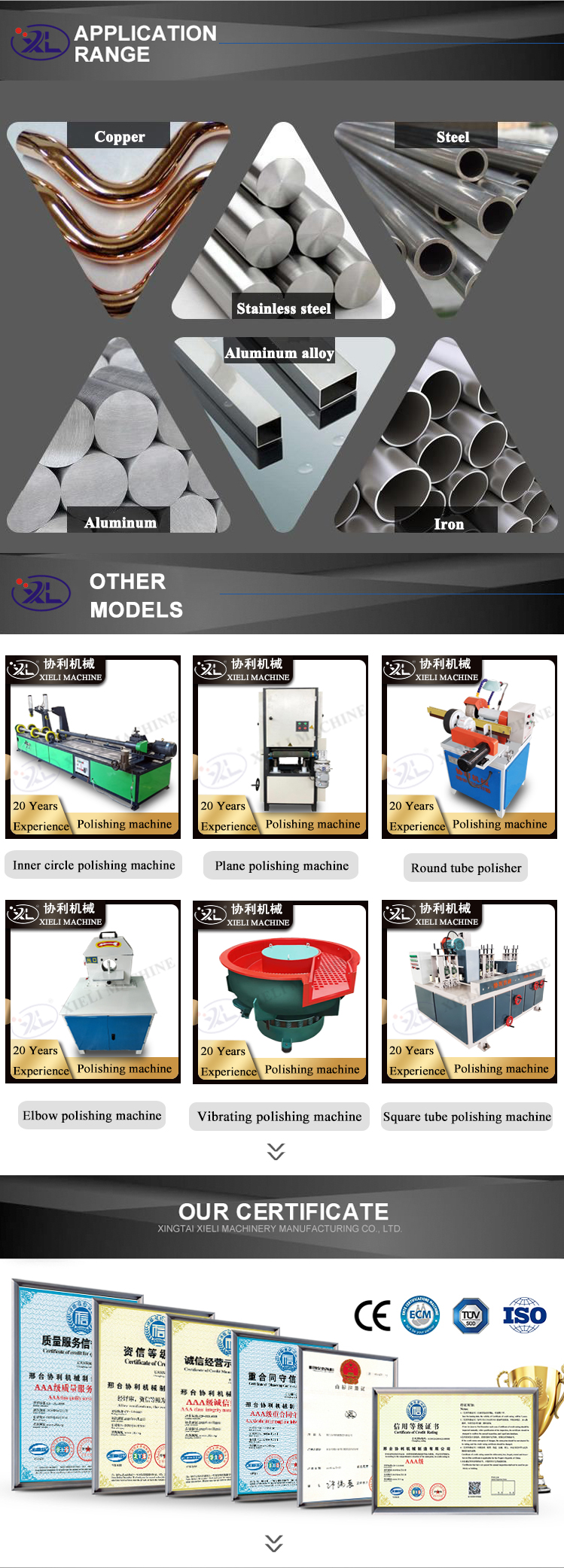

Materials selection is another critical aspect of Micron centerless grinder manufacturing. The machining process requires robust and durable components that can withstand the extreme conditions imposed by high-speed grinding operations. Factories often utilize precision steel, hardened alloys, and advanced composite materials in their machine construction to ensure longevity and reliability.

micron centerless grinder factories

Furthermore, quality control processes are paramount in these factories. At every stage of production, rigorous inspections are conducted to guarantee that every grinder meets the industry's stringent standards. Advanced measurement systems, such as laser scanning and coordinate measuring machines, are routinely utilized to monitor the dimensional accuracy and surface finish of the components. This dedication to quality ensures that Micron centerless grinders provide consistent performance, resulting in higher productivity and lower operational costs for manufacturers.

The role of skilled labor cannot be understated in the realm of Micron centerless grinder factories. Highly trained technicians and engineers are essential to operating and maintaining the sophisticated machinery used in production. Continuous training and development programs are implemented within these factories to ensure that staff members are up-to-date with the latest advancements in technology and manufacturing practices.

As global manufacturing trends shift toward increased sustainability and reduced environmental impact, Micron centerless grinder factories are also embracing these changes. Many facilities are investing in energy-efficient technologies and sustainable practices to minimize waste and energy consumption. This shift not only contributes to a healthier planet but also results in cost savings for manufacturers in the long run.

In conclusion, Micron centerless grinder factories exemplify the intersection of precision engineering and technological innovation in the manufacturing industry. With their focus on quality, efficiency, and sustainability, these facilities are positioned to meet the challenges of modern production while delivering top-notch grinding solutions to a wide array of industries. As they continue to evolve and adapt to changing market demands, the significance of Micron centerless grinder factories will only grow, ensuring their place as leaders in precision manufacturing.